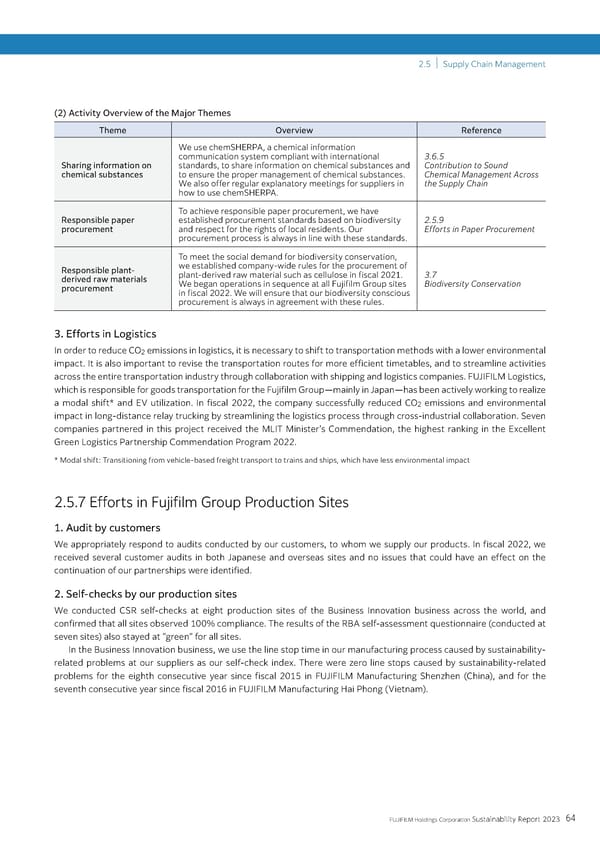

2.5 | Supply Chain Management (2) Activity Overview of the Major Themes Theme Overview Reference We use chemSHERPA, a chemical information communication system compliant with international 3.6.5 Sharing information on standards, to share information on chemical substances and Contribution to Sound chemical substances to ensure the proper management of chemical substances. Chemical Management Across We also offer regular explanatory meetings for suppliers in the Supply Chain how to use chemSHERPA. To achieve responsible paper procurement, we have Responsible paper established procurement standards based on biodiversity 2.5.9 procurement and respect for the rights of local residents. Our Efforts in Paper Procurement procurement process is always in line with these standards. To meet the social demand for biodiversity conservation, Responsible plant- we established company-wide rules for the procurement of derived raw materials plant-derived raw material such as cellulose in fiscal 2021. 3.7 procurement We began operations in sequence at all Fujifilm Group sites Biodiversity Conservation in fiscal 2022. We will ensure that our biodiversity conscious procurement is always in agreement with these rules. 3. Efforts in Logistics In order to reduce CO emissions in logistics, it is necessary to shift to transportation methods with a lower environmental 2 impact. It is also important to revise the transportation routes for more efficient timetables, and to streamline activities across the entire transportation industry through collaboration with shipping and logistics companies. FUJIFILM Logistics, which is responsible for goods transportation for the Fujifilm Group—mainly in Japan—has been actively working to realize a modal shift* and EV utilization. In fiscal 2022, the company successfully reduced CO emissions and environmental 2 impact in long-distance relay trucking by streamlining the logistics process through cross-industrial collaboration. Seven companies partnered in this project received the MLIT Minister's Commendation, the highest ranking in the Excellent Green Logistics Partnership Commendation Program 2022. * Modal shift: Transitioning from vehicle-based freight transport to trains and ships, which have less environmental impact 2.5.7 Efforts in Fujifilm Group Production Sites 1. Audit by customers We appropriately respond to audits conducted by our customers, to whom we supply our products. In fiscal 2022, we received several customer audits in both Japanese and overseas sites and no issues that could have an effect on the continuation of our partnerships were identified. 2. Self-checks by our production sites We conducted CSR self-checks at eight production sites of the Business Innovation business across the world, and confirmed that all sites observed 100% compliance. The results of the RBA self-assessment questionnaire (conducted at seven sites) also stayed at “green” for all sites. In the Business Innovation business, we use the line stop time in our manufacturing process caused by sustainability- related problems at our suppliers as our self-check index. There were zero line stops caused by sustainability-related problems for the eighth consecutive year since fiscal 2015 in FUJIFILM Manufacturing Shenzhen (China), and for the seventh consecutive year since fiscal 2016 in FUJIFILM Manufacturing Hai Phong (Vietnam). 64 FUJIFILM Holdings Corporation Sustainability Report 2023

2023 | Sustainability Report Page 64 Page 66

2023 | Sustainability Report Page 64 Page 66