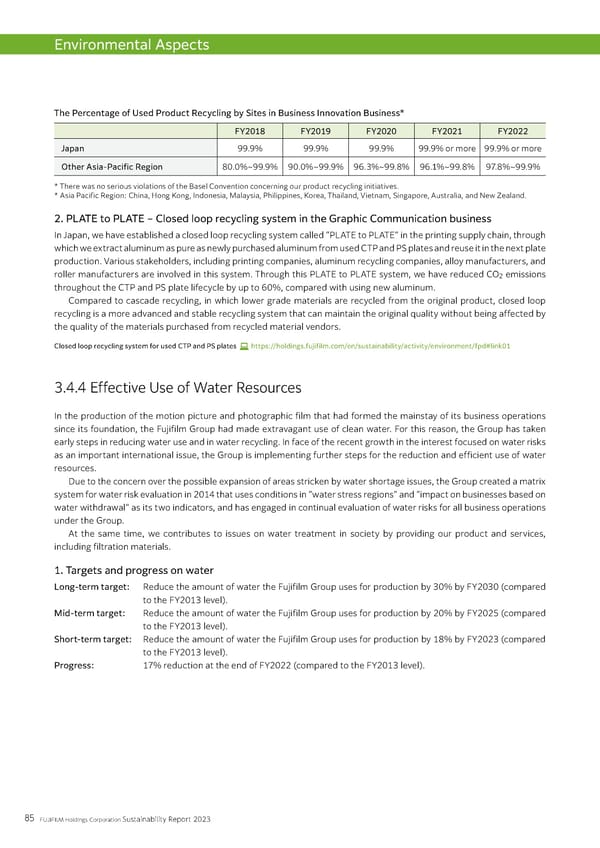

Environmental Aspects The Percentage of Used Product Recycling by Sites in Business Innovation Business* FY2018 FY2019 FY2020 FY2021 FY2022 Japan 99.9% 99.9% 99.9% 99.9% or more 99.9% or more Other Asia-Pacific Region 80.0%~99.9% 90.0%~99.9% 96.3%~99.8% 96.1%~99.8% 97.8%~99.9% * There was no serious violations of the Basel Convention concerning our product recycling initiatives. * Asia Pacific Region: China, Hong Kong, Indonesia, Malaysia, Philippines, Korea, Thailand, Vietnam, Singapore, Australia, and New Zealand. 2. PLATE to PLATE – Closed loop recycling system in the Graphic Communication business In Japan, we have established a closed loop recycling system called “PLATE to PLATE” in the printing supply chain, through which we extract aluminum as pure as newly purchased aluminum from used CTP and PS plates and reuse it in the next plate production. Various stakeholders, including printing companies, aluminum recycling companies, alloy manufacturers, and roller manufacturers are involved in this system. Through this PLATE to PLATE system, we have reduced CO emissions 2 throughout the CTP and PS plate lifecycle by up to 60%, compared with using new aluminum. Compared to cascade recycling, in which lower grade materials are recycled from the original product, closed loop recycling is a more advanced and stable recycling system that can maintain the original quality without being affected by the quality of the materials purchased from recycled material vendors. Closed loop recycling system for used CTP and PS plates https://holdings.fujifilm.com/en/sustainability/activity/environment/fpd#link01 3.4.4 Effective Use of Water Resources In the production of the motion picture and photographic film that had formed the mainstay of its business operations since its foundation, the Fujifilm Group had made extravagant use of clean water. For this reason, the Group has taken early steps in reducing water use and in water recycling. In face of the recent growth in the interest focused on water risks as an important international issue, the Group is implementing further steps for the reduction and efficient use of water resources. Due to the concern over the possible expansion of areas stricken by water shortage issues, the Group created a matrix system for water risk evaluation in 2014 that uses conditions in “water stress regions” and “impact on businesses based on water withdrawal” as its two indicators, and has engaged in continual evaluation of water risks for all business operations under the Group. At the same time, we contributes to issues on water treatment in society by providing our product and services, including filtration materials. 1. Targets and progress on water Long-term target: Reduce the amount of water the Fujifilm Group uses for production by 30% by FY2030 (compared to the FY2013 level). Mid-term target: Reduce the amount of water the Fujifilm Group uses for production by 20% by FY2025 (compared to the FY2013 level). Short-term target: Reduce the amount of water the Fujifilm Group uses for production by 18% by FY2023 (compared to the FY2013 level). Progress: 17% reduction at the end of FY2022 (compared to the FY2013 level). 85 FUJIFILM Holdings Corporation Sustainability Report 2023

2023 | Sustainability Report Page 85 Page 87

2023 | Sustainability Report Page 85 Page 87