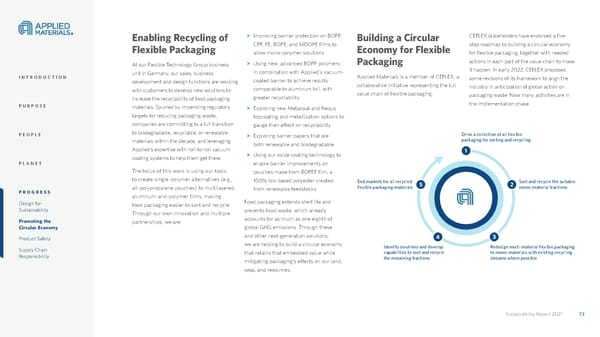

Sustainability Report 2021 73 Enabling Recycling of Flexible Packaging At our Flexible Technology Group business unit in Germany, our sales, business development and design functions are working with customers to develop new solutions to increase the recyclability of food packaging materials. Spurred by impending regulatory targets for reducing packaging waste, companies are committing to a full transition to biodegradable, recyclable, or renewable materials within the decade, and leveraging Applied’s expertise with roll-to-roll vacuum coating systems to help them get there. The focus of this work is using our tools to create single-polymer alternatives (e.g., all-polypropylene pouches) to multilayered aluminum-and-polymer films, making food packaging easier to sort and recycle. Through our own innovation and multiple partnerships, we are: > Improving barrier protection on BOPP, CPP, PE, BOPE, and MDOPE films to allow mono-polymer solutions > Using new, advanced BOPP polymers in combination with Applied’s vacuum- coated barrier to achieve results comparable to aluminum foil, with greater recyclability > Exploring new Metacoat and Nexus topcoating and metallization options to gauge their effect on recyclability > Exploring barrier papers that are both renewable and biodegradable > Using our oxide coating technology to enable barrier improvements on pouches made from BOPEF film, a 100% bio-based polyester created from renewable feedstocks Food packaging extends shelf life and prevents food waste, which already accounts for as much as one eighth of global GHG emissions. Through these and other next-generation solutions, we are helping to build a circular economy that retains that embedded value while mitigating packaging’s effects on our land, seas, and resources. Building a Circular Economy for Flexible Packaging Applied Materials is a member of CEFLEX, a collaborative initiative representing the full value chain of flexible packaging. CEFLEX stakeholders have endorsed a five- step roadmap to building a circular economy for flexible packaging, together with needed actions in each part of the value chain to make it happen. In early 2022, CEFLEX proposed some revisions of its framework to align the industry in anticipation of global action on packaging waste. Now many activities are in the implementation phase. 1 2 3 4 5 Drive a collection of all flexible packaging for sorting and recycling Sort and recycle the suitable mono-material fractions Redesign multi-material flexible packaging to mono-materials with existing recycling streams where possible Identify solutions and develop capabilities to sort and recycle the remaining fractions End markets for all recycled flexible packaging materials INTRODUCTION PURPOSE PEOPLE PLANET PROGRESS Design for Sustainability Promoting the Circular Economy Product Safety Supply Chain Responsibility

Applied Materials Sustainability Report Page 72 Page 74

Applied Materials Sustainability Report Page 72 Page 74