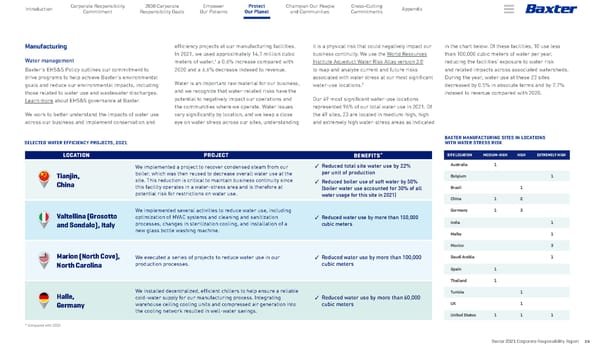

Baxter 2021 Corporate Responsibility Report 26 Protect Our Planet Corporate Responsibility Commitment Introduction 2030 Corporate Responsibility Goals Empower Our Patients Appendix Champion Our People and Communities Cross-Cutting Commitments Manufacturing Water management Baxter’s EHS&S Policy outlines our commitment to drive programs to help achieve Baxter’s environmental goals and reduce our environmental impacts, including those related to water use and wastewater discharges . Learn more about EHS&S governance at Baxter. We work to better understand the impacts of water use across our business and implement conservation and efficiency projects at our manufacturing facilities. In 2021, we used approximately 14.7 million cubic meters of water, 1 a 0.6% increase compared with 2020 and a 6.6% decrease indexed to revenue. Water is an important raw material for our business, and we recognize that water-related risks have the potential to negatively impact our operations and the communities where we operate. Water issues vary significantly by location, and we keep a close eye on water stress across our sites, understanding it is a physical risk that could negatively impact our business continuity. We use the World Resources Institute Aqueduct Water Risk Atlas version 3.0 to map and analyze current and future risks associated with water stress at our most significant water-use locations. 2 Our 49 most significant water-use locations represented 96% of our total water use in 2021. Of the 49 sites, 23 are located in medium-high, high and extremely high water-stress areas as indicated in the chart below. Of these facilities, 10 use less than 100,000 cubic meters of water per year, reducing the facilities’ exposure to water risk and related impacts across associated watersheds. During the year, water use at these 23 sites decreased by 0.5% in absolute terms and by 7.7% indexed to revenue compared with 2020. SELECTED WATER EFFICIENCY PROJECTS, 2021 BAXTER MANUFACTURING SITES IN LOCATIONS WITH WATER STRESS RISK LOCATION PROJECT BENEFITS * Tianjin, China We implemented a project to recover condensed steam from our boiler, which was then reused to decrease overall water use at the site. This reduction is critical to maintain business continuity since this facility operates in a water-stress area and is therefore at potential risk for restrictions on water use. ✓ Reduced total site water use by 22% per unit of production ✓ Reduced boiler use of soft water by 50% (boiler water use accounted for 30% of all water usage for this site in 2021) Valtellina (Grosotto and Sondalo), Italy We implemented several activities to reduce water use, including optimization of HVAC systems and cleaning and sanitization processes, changes in sterilization cooling, and installation of a new glass bottle washing machine. ✓ Reduced water use by more than 150,000 cubic meters Marion (North Cove), North Carolina We executed a series of projects to reduce water use in our production processes. ✓ Reduced water use by more than 100,000 cubic meters Halle, Germany We installed decentralized, efficient chillers to help ensure a reliable cold-water supply for our manufacturing process. Integrating warehouse ceiling cooling units and compressed air generation into the cooling network resulted in well-water savings. ✓ Reduced water use by more than 60,000 cubic meters SITE LOCATION MEDIUM-HIGH HIGH EXTREMELY HIGH Australia 1 Belgium 1 Brazil 1 China 1 2 Germany 1 3 India 1 Malta 1 Mexico 3 Saudi Arabia 1 Spain 1 Thailand 1 Tunisia 1 UK 1 United States 1 1 1 * Compared with 2020.

Baxter Corporate Responsibility Report Page 25 Page 27

Baxter Corporate Responsibility Report Page 25 Page 27