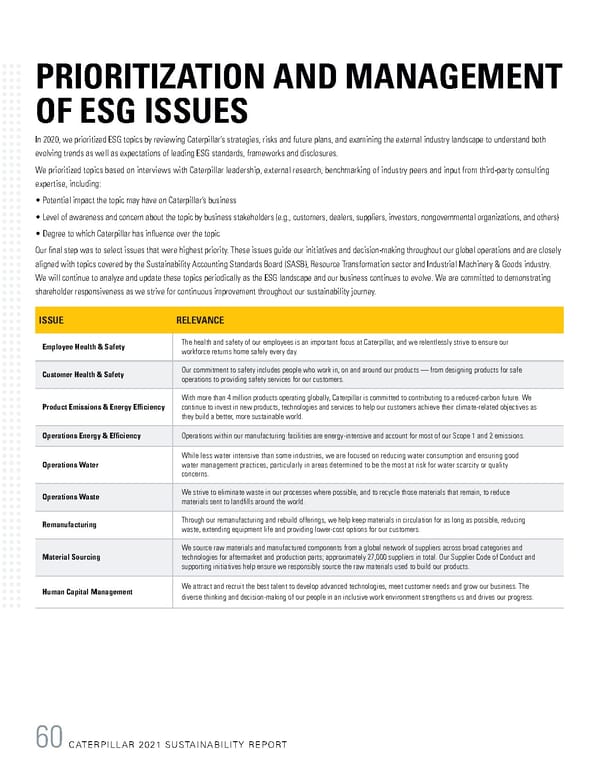

PRIORITIZATION AND MANAGEMENT OF ESG ISSUES In 2020, we prioritized ESG topics by reviewing Caterpillar’s strategies, risks and future plans, and examining the external industry landscape to understand both evolving trends as well as expectations of leading ESG standards, frameworks and disclosures. We prioritized topics based on interviews with Caterpillar leadership, external research, benchmarking of industry peers and input from third-party consulting expertise, including: • Potential impact the topic may have on Caterpillar’s business • Level of awareness and concern about the topic by business stakeholders (e.g., customers, dealers, suppliers, investors, nongovernmental organizations, and others) • Degree to which Caterpillar has influence over the topic Our final step was to select issues that were highest priority. These issues guide our initiatives and decision-making throughout our global operations and are closely aligned with topics covered by the Sustainability Accounting Standards Board (SASB), Resource Transformation sector and Industrial Machinery & Goods industry. We will continue to analyze and update these topics periodically as the ESG landscape and our business continues to evolve. We are committed to demonstrating shareholder responsiveness as we strive for continuous improvement throughout our sustainability journey. ISSUE RELEVANCE Employee Health & Safety The health and safety of our employees is an important focus at Caterpillar, and we relentlessly strive to ensure our workforce returns home safely every day. Customer Health & Safety Our commitment to safety includes people who work in, on and around our products — from designing products for safe operations to providing safety services for our customers. With more than 4 million products operating globally, Caterpillar is committed to contributing to a reduced-carbon future. We Product Emissions & Energy Efficiency continue to invest in new products, technologies and services to help our customers achieve their climate-related objectives as they build a better, more sustainable world. Operations Energy & Efficiency Operations within our manufacturing facilities are energy-intensive and account for most of our Scope 1 and 2 emissions. While less water intensive than some industries, we are focused on reducing water consumption and ensuring good Operations Water water management practices, particularly in areas determined to be the most at risk for water scarcity or quality concerns. Operations Waste We strive to eliminate waste in our processes where possible, and to recycle those materials that remain, to reduce materials sent to landfills around the world. Remanufacturing Through our remanufacturing and rebuild offerings, we help keep materials in circulation for as long as possible, reducing waste, extending equipment life and providing lower-cost options for our customers. We source raw materials and manufactured components from a global network of suppliers across broad categories and Material Sourcing technologies for aftermarket and production parts; approximately 27,000 suppliers in total. Our Supplier Code of Conduct and supporting initiatives help ensure we responsibly source the raw materials used to build our products. Human Capital Management We attract and recruit the best talent to develop advanced technologies, meet customer needs and grow our business. The diverse thinking and decision-making of our people in an inclusive work environment strengthens us and drives our progress. 60CATERPILLAR 2021 SUSTAINABILITY REPORT

Caterpillar Sustainability Report Page 59 Page 61

Caterpillar Sustainability Report Page 59 Page 61