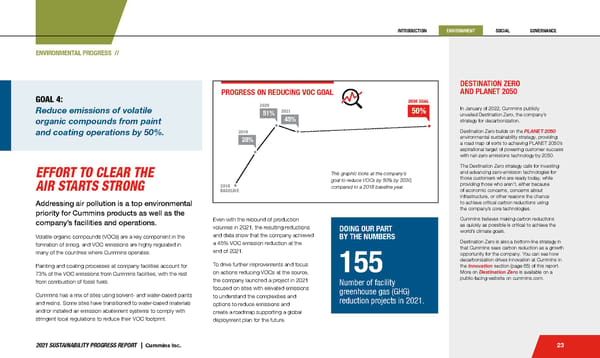

2021 SUSTAINABILITY PROGRESS REPORT | Cummins Inc. PROGRESS ON REDUCING VOC GOAL 2018 BASELINE 2019 28% 2020 51% 2021 45% 2030 GOAL 50% This graphic looks at the company’s goal to reduce VOCs by 50% by 2030, compared to a 2018 baseline year. DESTINATION ZERO AND PLANET 2050 In January of 2022, Cummins publicly unveiled Destination Zero, the company’s strategy for decarbonization. Destination Zero builds on the PLANET 2050 environmental sustainability strategy, providing a road map of sorts to achieving PLANET 2050’s aspirational target of powering customer success with net-zero emissions technology by 2050. The Destination Zero strategy calls for investing and advancing zero-emission technologies for those customers who are ready today, while providing those who aren’t, either because of economic concerns, concerns about infrastructure, or other reasons the chance to achieve critical carbon reductions using the company’s core technologies. Cummins believes making carbon reductions as quickly as possible is critical to achieve the world’s climate goals. Destination Zero is also a bottom-line strategy in that Cummins sees carbon reduction as a growth opportunity for the company. You can see how decarbonization drives innovation at Cummins in the Innovation section (page 65) of this report. More on Destination Zero is available on a public-facing website on cummins.com. ENVIRONMENTAL PROGRESS // 23 Even with the rebound of production volumes in 2021, the resulting reductions and data show that the company achieved a 45% VOC emission reduction at the end of 2021. To drive further improvements and focus on actions reducing VOCs at the source, the company launched a project in 2021 focused on sites with elevated emissions to understand the complexities and options to reduce emissions and create a roadmap supporting a global deployment plan for the future. GOAL 4: Reduce emissions of volatile organic compounds from paint and coating operations by 50%. EFFORT TO CLEAR THE AIR STARTS STRONG Addressing air pollution is a top environmental priority for Cummins products as well as the company’s facilities and operations. Volatile organic compounds (VOCs) are a key component in the formation of smog, and VOC emissions are highly regulated in many of the countries where Cummins operates. Painting and coating processes at company facilities account for 73% of the VOC emissions from Cummins facilities, with the rest from combustion of fossil fuels. Cummins has a mix of sites using solvent- and water-based paints and resins. Some sites have transitioned to water-based materials and/or installed air emission abatement systems to comply with stringent local regulations to reduce their VOC footprint. DOING OUR PART BY THE NUMBERS 155 Number of facility greenhouse gas (GHG) reduction projects in 2021.

Cummins Sustainability Progress Report Page 23 Page 25

Cummins Sustainability Progress Report Page 23 Page 25