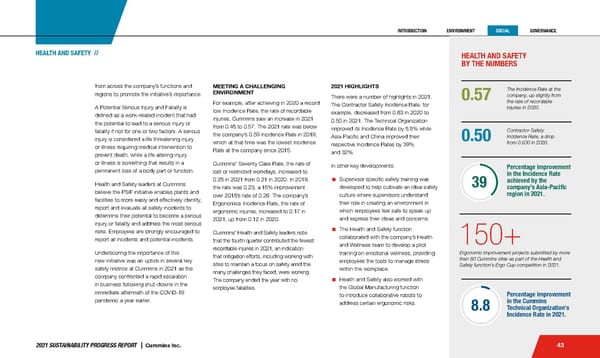

2021 SUSTAINABILITY PROGRESS REPORT | Cummins Inc. 43 2021 HIGHLIGHTS There were a number of highlights in 2021. The Contractor Safety Incidence Rate, for example, decreased from 0.63 in 2020 to 0.50 in 2021. The Technical Organization improved its Incidence Rate by 8.8% while Asia-Pacific and China improved their respective Incidence Rates by 39% and 32%. In other key developments: Supervisor specific safety training was developed to help cultivate an ideal safety culture where supervisors understand their role in creating an environment in which employees feel safe to speak up and express their ideas and concerns. The Health and Safety function collaborated with the company’s Health and Wellness team to develop a pilot training on emotional wellness, providing employees the tools to manage stress within the workplace. Health and Safety also worked with the Global Manufacturing function to introduce collaborative robots to address certain ergonomic risks. MEETING A CHALLENGING ENVIRONMENT For example, after achieving in 2020 a record low Incidence Rate, the rate of recordable injuries, Cummins saw an increase in 2021 from 0.48 to 0.57. The 2021 rate was below the company’s 0.59 Incidence Rate in 2019, which at that time was the lowest Incidence Rate at the company since 2015. Cummins’ Severity Case Rate, the rate of lost or restricted workdays, increased to 0.28 in 2021 from 0.21 in 2020. In 2019, the rate was 0.23, a 15% improvement over 2018’s rate of 0.26. The company’s Ergonomics Incidence Rate, the rate of ergonomic injuries, increased to 0.17 in 2021, up from 0.12 in 2020. Cummins’ Health and Safety leaders note that the fourth quarter contributed the fewest recordable injuries in 2021, an indication that mitigation efforts, including working with sites to maintain a focus on safety amid the many challenges they faced, were working. The company ended the year with no employee fatalities. from across the company’s functions and regions to promote the initiative’s importance. A Potential Serious Injury and Fatality is defined as a work-related incident that had the potential to lead to a serious injury or fatality if not for one or two factors. A serious injury is considered a life threatening injury or illness requiring medical intervention to prevent death, while a life altering injury or illness is something that results in a permanent loss of a body part or function. Health and Safety leaders at Cummins believe the PSIF initiative enables plants and facilities to more easily and effectively identify, report and evaluate all safety incidents to determine their potential to become a serious injury or fatality and address the most serious risks. Employees are strongly encouraged to report all incidents and potential incidents. Underscoring the importance of this new initiative was an uptick in several key safety metrics at Cummins in 2021 as the company confronted a rapid escalation in business following shut-downs in the immediate aftermath of the COVID-19 pandemic a year earlier. HEALTH AND SAFETY BY THE NUMBERS 150+ Ergonomic improvement projects submitted by more than 60 Cummins sites as part of the Health and Safety function’s Ergo Cup competition in 2021. 0.57 39 Percentage improvement in the Incidence Rate achieved by the company’s Asia-Pacific region in 2021. 8.8 Percentage improvement in the Cummins Technical Organization’s Incidence Rate in 2021. The Incidence Rate at the company, up slightly from the rate of recordable injuries in 2020. 0.50 Contractor Safety Incidence Rate, a drop from 0.630 in 2020. HEALTH AND SAFETY //

Cummins Sustainability Progress Report Page 43 Page 45

Cummins Sustainability Progress Report Page 43 Page 45