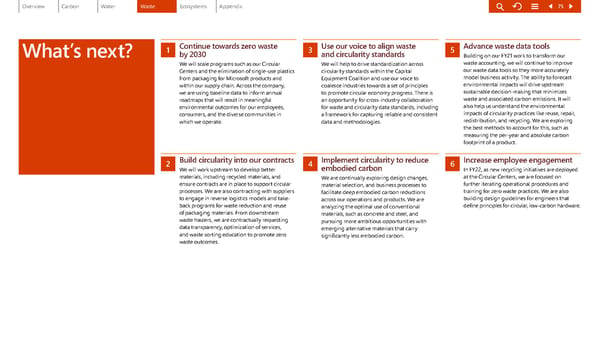

What’s next? 1 Continue towards zero waste by 2030 We will scale programs such as our Circular Centers and the elimination of single-use plastics from packaging for Microsoft products and within our supply chain. Across the company, we are using baseline data to inform annual roadmaps that will result in meaningful environmental outcomes for our employees, consumers, and the diverse communities in which we operate. 2 Build circularity into our contracts We will work upstream to develop better materials, including recycled materials, and ensure contracts are in place to support circular processes. We are also contracting with suppliers to engage in reverse logistics models and take- back programs for waste reduction and reuse of packaging materials. From downstream waste haulers, we are contractually requesting data transparency, optimization of services, and waste sorting education to promote zero waste outcomes. 3 Use our voice to align waste and circularity standards We will help to drive standardization across circularity standards within the Capital Equipment Coalition and use our voice to coalesce industries towards a set of principles to promote circular economy progress. There is an opportunity for cross-industry collaboration for waste and circularity data standards, including a framework for capturing reliable and consistent data and methodologies. 4 Implement circularity to reduce embodied carbon We are continually exploring design changes, material selection, and business processes to facilitate deep embodied carbon reductions across our operations and products. We are analyzing the optimal use of conventional materials, such as concrete and steel, and pursuing more ambitious opportunities with emerging alternative materials that carry significantly less embodied carbon. 5 Advance waste data tools Building on our FY21 work to transform our waste accounting, we will continue to improve our waste data tools so they more accurately model business activity. The ability to forecast environmental impacts will drive upstream sustainable decision-making that minimizes waste and associated carbon emissions. It will also help us understand the environmental impacts of circularity practices like reuse, repair, redistribution, and recycling. We are exploring the best methods to account for this, such as measuring the per-year and absolute carbon footprint of a product. 6 Increase employee engagement In FY22, as new recycling initiatives are deployed at the Circular Centers, we are focused on further iterating operational procedures and training for zero waste practices. We are also building design guidelines for engineers that define principles for circular, low-carbon hardware. 75

Environmental Sustainability Report | Microsoft Page 74 Page 76

Environmental Sustainability Report | Microsoft Page 74 Page 76