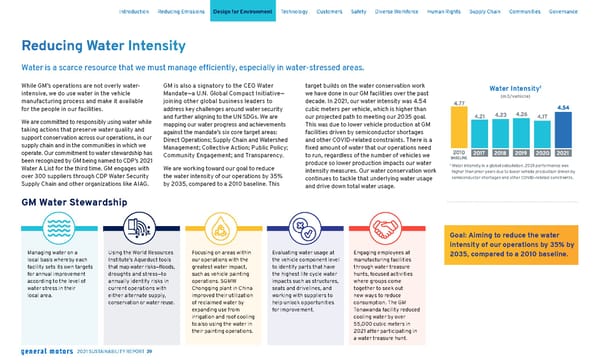

Reducing Water Intensity Water is a scarce resource that we must manage efficiently, especially in water-stressed areas. While GM’s operations are not overly water- intensive, we do use water in the vehicle manufacturing process and make it available for the people in our facilities. We are committed to responsibly using water while taking actions that preserve water quality and support conservation across our operations, in our supply chain and in the communities in which we operate. Our commitment to water stewardship has been recognized by GM being named to CDP’s 2021 Water A List for the third time. GM engages with over 300 suppliers through CDP Water Security Supply Chain and other organizations like AIAG. GM is also a signatory to the CEO Water Mandate—a U.N. Global Compact Initiative— joining other global business leaders to address key challenges around water security and further aligning to the UN SDGs. We are mapping our water progress and achievements against the mandate’s six core target areas: Direct Operations; Supply Chain and Watershed Management; Collective Action; Public Policy; Community Engagement; and Transparency. We are working toward our goal to reduce the water intensity of our operations by 35% by 2035, compared to a 2010 baseline. This target builds on the water conservation work we have done in our GM facilities over the past decade. In 2021, our water intensity was 4.54 cubic meters per vehicle, which is higher than our projected path to meeting our 2035 goal. This was due to lower vehicle production at GM facilities driven by semiconductor shortages and other COVID-related constraints. There is a fixed amount of water that our operations need to run, regardless of the number of vehicles we produce so lower production impacts our water intensity measures. Our water conservation work continues to tackle that underlying water usage and drive down total water usage. GM Water Stewardship Managing water on a local basis whereby each facility sets its own targets for annual improvement according to the level of water stress in their local area. Using the World Resources Institute’s Aqueduct tools that map water risks—floods, droughts and stress—to annually identify risks in current operations with either alternate supply, conservation or water reuse. Focusing on areas within our operations with the greatest water impact, such as vehicle painting operations. SGMW Chongqing plant in China improved their utilization of reclaimed water by expanding use from irrigation and roof cooling to also using the water in their painting operations. Evaluating water usage at the vehicle component level to identify parts that have the highest life cycle water impacts such as structures, seats and drivelines, and working with suppliers to help unlock opportunities for improvement. Engaging employees at manufacturing facilities through water treasure hunts, focused activities where groups come together to seek out new ways to reduce consumption. The GM Tonawanda facility reduced cooling water by over 55,000 cubic meters in 2021 after participating in a water treasure hunt. Water Intensity 1 (m3/vehicle) 2018 2020 2021 2019 1 W ater intensity is a global calculation. 2021 performance was higher than prior years due to lower vehicle production driven by semiconductor shortages and other COVID-related constraints. Goal: Aiming to reduce the water intensity of our operations by 35% by 2035, compared to a 2010 baseline. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 39

General Motors Sustainability Report Page 39 Page 41

General Motors Sustainability Report Page 39 Page 41