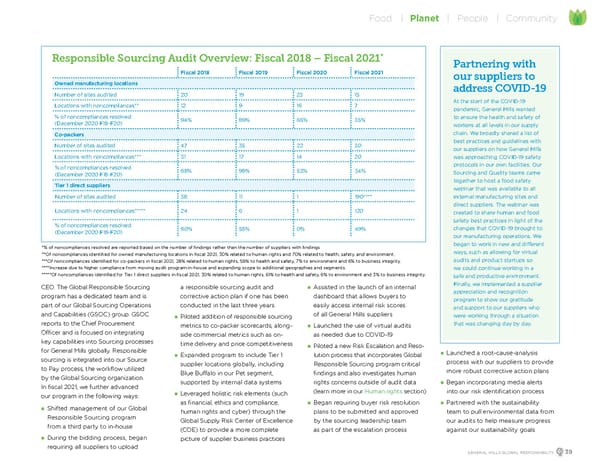

CEO. The Global Responsible Sourcing program has a dedicated team and is part of our Global Sourcing Operations and Capabilities (GSOC) group. GSOC reports to the Chief Procurement Officer and is focused on integrating key capabilities into Sourcing processes for General Mills globally. Responsible sourcing is integrated into our Source to Pay process, the workflow utilized by the Global Sourcing organization. In fiscal 2021, we further advanced our program in the following ways: n Shifted management of our Global Responsible Sourcing program from a third party to in-house n During the bidding process, began requiring all suppliers to upload a responsible sourcing audit and corrective action plan if one has been conducted in the last three years n Piloted addition of responsible sourcing metrics to co-packer scorecards, along - side commercial metrics such as on- time delivery and price competitiveness n Expanded program to include Tier 1 supplier locations globally, including Blue Buffalo in our Pet segment, supported by internal data systems n Leveraged holistic risk elements (such as financial, ethics and compliance, human rights and cyber) through the Global Supply Risk Center of Excellence (COE) to provide a more complete picture of supplier business practices n Assisted in the launch of an internal dashboard that allows buyers to easily access internal risk scores of all General Mills suppliers n Launched the use of virtual audits as needed due to COVID-19 n Piloted a new Risk Escalation and Reso - lution process that incorporates Global Responsible Sourcing program critical findings and also investigates human rights concerns outside of audit data (learn more in our Human rights section) n Began requiring buyer risk resolution plans to be submitted and approved by the sourcing leadership team as part of the escalation process n Launched a root-cause-analysis process with our suppliers to provide more robust corrective action plans n Began incorporating media alerts into our risk identification process n Partnered with the sustainability team to pull environmental data from our audits to help measure progress against our sustainability goals At the start of the COVID-19 pandemic, General Mills wanted to ensure the health and safety of workers at all levels in our supply chain. We broadly shared a list of best practices and guidelines with our suppliers on how General Mills was approaching COVID-19 safety protocols in our own facilities. Our Sourcing and Quality teams came together to host a food safety webinar that was available to all external manufacturing sites and direct suppliers. The webinar was created to share human and food safety best practices in light of the changes that COVID-19 brought to our manufacturing operations. We began to work in new and different ways, such as allowing for virtual audits and product startups so we could continue working in a safe and productive environment. Finally, we implemented a supplier appreciation and recognition program to show our gratitude and support to our suppliers who were working through a situation that was changing day by day. Partnering with our suppliers to address COVID-19 *% of noncompliances resolved are reported based on the number of findings rather than the number of suppliers with findings **Of noncompliances identified for owned manufacturing locations in fiscal 2021, 30% related to human rights and 70% related to health, safety, and environment. ***Of noncompliances identified for co-packers in fiscal 2021, 28% related to human rights, 59% to health and safety, 7% to environment and 6% to business integrity. ****Increase due to higher compliance from moving audit program in-house and expanding scope to additional geographies and segments. *****Of noncompliances identified for Tier 1 direct suppliers in fiscal 2021, 30% related to human rights, 61% to health and safety, 6% to environment and 3% to business integrity. Fiscal 2018 Fiscal 2019 Fiscal 2020 Fiscal 2021 Owned manufacturing locations Number of sites audited 20 19 23 15 Locations with noncompliances** 12 9 16 7 % of noncompliances resolved (December 2020 F18-F20) 94% 89% 65% 35% Co-packers Number of sites audited 47 35 22 30 Locations with noncompliances*** 31 17 14 20 % of noncompliances resolved (December 2020 F18-F20) 68% 98% 53% 34% Tier 1 direct suppliers Number of sites audited 38 11 1 190**** Locations with noncompliances***** 24 6 1 120 % of noncompliances resolved (December 2020 F18-F20) 60% 55% 0% 49% Responsible Sourcing Audit Overview: Fiscal 2018 – Fiscal 2021 * GENERAL MILLS GLOBAL RESPONSIBILITY 39 Food Planet People Community

GeneralMills Global Responsibility Report Page 40 Page 42

GeneralMills Global Responsibility Report Page 40 Page 42