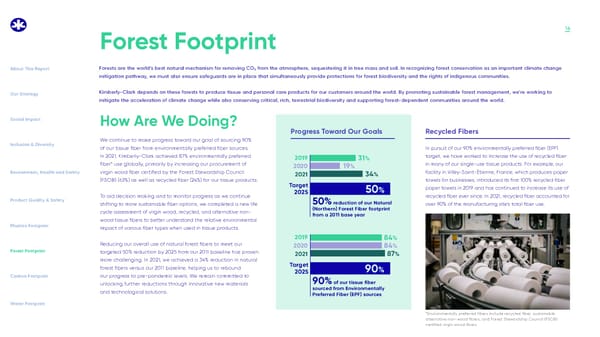

16 How Are We Doing? We continue to make progress toward our goal of sourcing 90% of our tissue fiber from environmentally preferred fiber sources. In 2021, Kimberly-Clark achieved 87% environmentally preferred fiber* use globally, primarily by increasing our procurement of virgin wood fiber certified by the Forest Stewardship Council (FSC®) (63%) as well as recycled fiber (24%) for our tissue products. To aid decision making and to monitor progress as we continue shifting to more sustainable fiber options, we completed a new life cycle assessment of virgin wood, recycled, and alternative non- wood tissue fibers to better understand the relative environmental impact of various fiber types when used in tissue products. Reducing our overall use of natural forest fibers to meet our targeted 50% reduction by 2025 from our 2011 baseline has proven more challenging. In 2021, we achieved a 34% reduction in natural forest fibers versus our 2011 baseline, helping us to rebound our progress to pre-pandemic levels. We remain committed to unlocking further reductions through innovative new materials and technological solutions. 90% of our tissue fiber sourced from Environmentally Preferred Fiber (EPF) sources Target 2025 2019 2020 2021 84 % 84 % 87 % Forest Footprint Forests are the world’s best natural mechanism for removing CO2 from the atmosphere, sequestering it in tree mass and soil. In recognizing forest conservation as an important climate change mitigation pathway, we must also ensure safeguards are in place that simultaneously provide protections for forest biodiversity and the rights of indigenous communities. Kimberly-Clark depends on these forests to produce tissue and personal care products for our customers around the world. By promoting sustainable forest management, we’re working to mitigate the acceleration of climate change while also conserving critical, rich, terrestrial biodiversity and supporting forest-dependent communities around the world. Recycled Fibers In pursuit of our 90% environmentally preferred fiber (EPF) target, we have worked to increase the use of recycled fiber in many of our single-use tissue products. For example, our facility in Villey-Saint-Étienne, France, which produces paper towels for businesses, introduced its first 100% recycled fiber paper towels in 2019 and has continued to increase its use of recycled fiber ever since. In 2021, recycled fiber accounted for over 90% of the manufacturing site’s total fiber use. *Environmentally preferred fibers include recycled fiber, sustainable alternative non-wood fibers, and Forest Stewardship Council (FSC®) certified virgin wood fibers Progress Toward Our Goals 50% reduction of our Natural (Northern) Forest Fiber footprint from a 2011 base year Target 2025 2019 2020 2021 19 % 31 % 34 % 50 % 90 % About This Report Social Impact Our Strategy Inclusion & Diversity Environment, Health and Safety Product Quality & Safety Plastics Footprint Forest Footprint Carbon Footprint Water Footprint

Kimberly-Clark Global Sustainability Report Page 15 Page 17

Kimberly-Clark Global Sustainability Report Page 15 Page 17