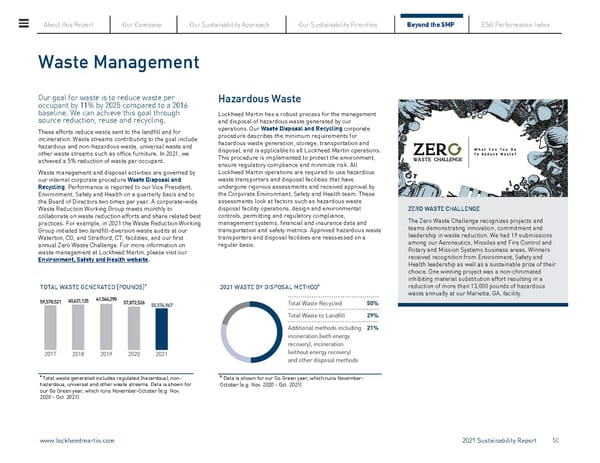

Waste Management Our goal for waste is to reduce waste per occupant by 11% by 2025 compared to a 2016 baseline. We can achieve this goal through source reduction, reuse and recycling. These efforts reduce waste sent to the landfill and for incineration. Waste streams contributing to the goal include hazardous and non-hazardous waste, universal waste and other waste streams such as office furniture. In 2021, we achieved a 5% reduction of waste per occupant. Waste management and disposal activities are governed by our internal corporate procedure Waste Disposal and Recycling . Performance is reported to our Vice President, Environment, Safety and Health on a quarterly basis and to the Board of Directors two times per year. A corporate-wide Waste Reduction Working Group meets monthly to collaborate on waste reduction efforts and share related best practices. For example, in 2021 the Waste Reduction Working Group initiated two landfill-diversion waste audits at our Waterton, CO, and Stratford, CT, facilities, and our first annual Zero Waste Challenge. For more information on waste management at Lockheed Martin, please visit our Environment, Safety and Health website . TOTAL WASTE GENERATED [POUNDS] a a Total waste generated includes regulated (hazardous), non- hazardous, universal and other waste streams. Data is shown for our Go Green year, which runs November-October (e.g. Nov. 2020 - Oct. 2021). Hazardous Waste Lockheed Martin has a robust process for the management and disposal of hazardous waste generated by our operations. Our Waste Disposal and Recycling corporate procedure describes the minimum requirements for hazardous waste generation, storage, transportation and disposal, and is applicable to all Lockheed Martin operations. This procedure is implemented to protect the environment, ensure regulatory compliance and minimize risk. All Lockheed Martin operations are required to use hazardous waste transporters and disposal facilities that have undergone rigorous assessments and received approval by the Corporate Environment, Safety and Health team. These assessments look at factors such as hazardous waste disposal facility operations, design and environmental controls, permitting and regulatory compliance, management systems, financial and insurance data and transportation and safety metrics. Approved hazardous waste transporters and disposal facilities are reassessed on a regular basis. 2021 WASTE BY DISPOSAL METHOD b b Data is shown for our Go Green year, which runs November- October (e.g. Nov. 2020 - Oct. 2021). ZERO WASTE CHALLENGE The Zero Waste Challenge recognizes projects and teams demonstrating innovation, commitment and leadership in waste reduction. We had 19 submissions among our Aeronautics, Missiles and Fire Control and Rotary and Mission Systems business areas. Winners received recognition from Environment, Safety and Health leadership as well as a sustainable prize of their choice. One winning project was a non-chromated inhibiting material substitution effort resulting in a reduction of more than 13,000 pounds of hazardous waste annually at our Marietta, GA, facility. About this Report Our Company Our Sustainability Approach Our Sustainability Priorities Beyond the SMP ESG Performance Index www.lockheedmartin.com 2021 Sustainability Report 50

Lockheed Martin Sustainability Report Page 49 Page 51

Lockheed Martin Sustainability Report Page 49 Page 51