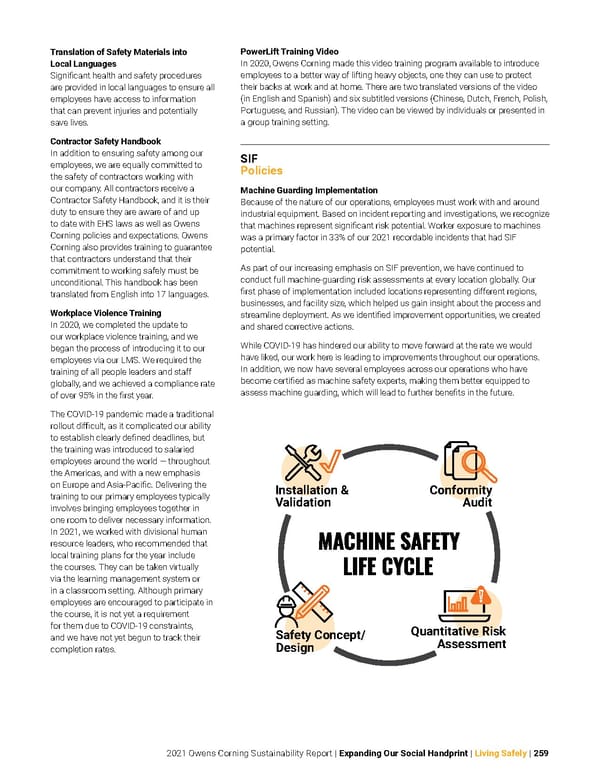

2021 Owens Corning Sustainability Report | Expanding Our Social Handprint | Living Safely | 259 Conformity Audit Quantitative Risk Assessmen t Safe ty Concept/ Design Installation & Va lidation Translation of Safety Materials into Local Languages Significant health and safety procedures are provided in local languages to ensure all employees have access to information that can prevent injuries and potentially save lives. Contractor Safety Handbook In addition to ensuring safety among our employees, we are equally committed to the safety of contractors working with our company. All contractors receive a Contractor Safety Handbook, and it is their duty to ensure they are aware of and up to date with EHS laws as well as Owens Corning policies and expectations. Owens Corning also provides training to guarantee that contractors understand that their commitment to working safely must be unconditional. This handbook has been translated from English into 17 languages. Workplace Violence Training In 2020, we completed the update to our workplace violence training, and we began the process of introducing it to our employees via our LMS. We required the training of all people leaders and staff globally, and we achieved a compliance rate of over 95% in the first year. The COVID-19 pandemic made a traditional rollout difficult, as it complicated our ability to establish clearly defined deadlines, but the training was introduced to salaried employees around the world — throughout the Americas, and with a new emphasis on Europe and Asia-Pacific. Delivering the training to our primary employees typically involves bringing employees together in one room to deliver necessary information. In 2021, we worked with divisional human resource leaders, who recommended that local training plans for the year include the courses. They can be taken virtually via the learning management system or in a classroom setting. Although primary employees are encouraged to participate in the course, it is not yet a requirement for them due to COVID-19 constraints, and we have not yet begun to track their completion rates. PowerLift Training Video In 2020, Owens Corning made this video training program available to introduce employees to a better way of lifting heavy objects, one they can use to protect their backs at work and at home. There are two translated versions of the video (in English and Spanish) and six subtitled versions (Chinese, Dutch, French, Polish, Portuguese, and Russian). The video can be viewed by individuals or presented in a group training setting. SIF Policies Machine Guarding Implementation Because of the nature of our operations, employees must work with and around industrial equipment. Based on incident reporting and investigations, we recognize that machines represent significant risk potential. Worker exposure to machines was a primary factor in 33% of our 2021 recordable incidents that had SIF potential. As part of our increasing emphasis on SIF prevention, we have continued to conduct full machine-guarding risk assessments at every location globally. Our first phase of implementation included locations representing different regions, businesses, and facility size, which helped us gain insight about the process and streamline deployment. As we identified improvement opportunities, we created and shared corrective actions. While COVID-19 has hindered our ability to move forward at the rate we would have liked, our work here is leading to improvements throughout our operations. In addition, we now have several employees across our operations who have become certified as machine safety experts, making them better equipped to assess machine guarding, which will lead to further benefits in the future.

Owens Corning Sustainability Report Page 258 Page 260

Owens Corning Sustainability Report Page 258 Page 260