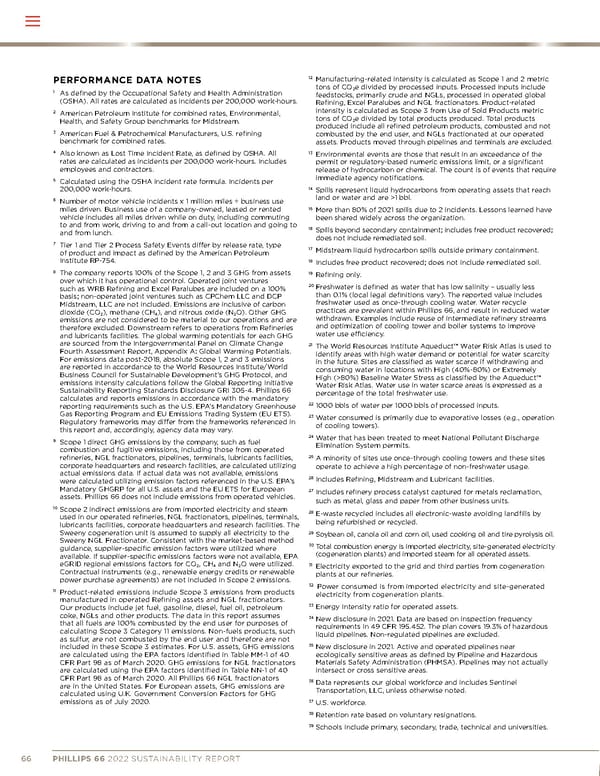

PERFORMANCE DATA NOTES 1 As defined by the Occupational Safety and Health Administration (OSHA). All rates are calculated as incidents per 200,000 work-hours. 2 American Petroleum Institute for combined rates, Environmental, Health, and Safety Group benchmarks for Midstream. 3 American Fuel & Petrochemical Manufacturers, U.S. refining benchmark for combined rates. 4 Also known as Lost Time Incident Rate, as defined by OSHA. All rates are calculated as incidents per 200,000 work-hours. Includes employees and contractors. 5 Calculated using the OSHA incident rate formula. Incidents per 200,000 work-hours. 6 Number of motor vehicle incidents x 1 million miles ÷ business use miles driven. Business use of a company-owned, leased or rented vehicle includes all miles driven while on duty, including commuting to and from work, driving to and from a call-out location and going to and from lunch. 7 Tier 1 and Tier 2 Process Safety Events differ by release rate, type of product and impact as defined by the American Petroleum Institute RP-754. 8 The company reports 100% of the Scope 1, 2 and 3 GHG from assets over which it has operational control. Operated joint ventures such as WRB Refining and Excel Paralubes are included on a 100% basis; non-operated joint ventures such as CPChem LLC and DCP Midstream, LLC are not included. Emissions are inclusive of carbon dioxide (CO₂), methane (CH₄), and nitrous oxide (N₂O). Other GHG emissions are not considered to be material to our operations and are therefore excluded. Downstream refers to operations from Refineries and lubricants facilities. The global warming potentials for each GHG are sourced from the Intergovernmental Panel on Climate Change Fourth Assessment Report, Appendix A: Global Warming Potentials. For emissions data post-2018, absolute Scope 1, 2 and 3 emissions are reported in accordance to the World Resources Institute/World Business Council for Sustainable Development’s GHG Protocol, and emissions intensity calculations follow the Global Reporting Initiative Sustainability Reporting Standards Disclosure GRI 305-4. Phillips 66 calculates and reports emissions in accordance with the mandatory reporting requirements such as the U.S. EPA’s Mandatory Greenhouse Gas Reporting Program and EU Emissions Trading System (EU ETS). Regulatory frameworks may differ from the frameworks referenced in this report and, accordingly, agency data may vary. 9 Scope 1 direct GHG emissions by the company, such as fuel combustion and fugitive emissions, including those from operated refineries, NGL fractionators, pipelines, terminals, lubricants facilities, corporate headquarters and research facilities, are calculated utilizing actual emissions data. If actual data was not available, emissions were calculated utilizing emission factors referenced in the U.S. EPA’s Mandatory GHGRP for all U.S. assets and the EU ETS for European assets. Phillips 66 does not include emissions from operated vehicles. 10 Scope 2 indirect emissions are from imported electricity and steam used in our operated refineries, NGL fractionators, pipelines, terminals, lubricants facilities, corporate headquarters and research facilities. The Sweeny cogeneration unit is assumed to supply all electricity to the Sweeny NGL Fractionator. Consistent with the market-based method guidance, supplier-specific emission factors were utilized where available. If supplier-specific emissions factors were not available, EPA eGRID regional emissions factors for CO₂, CH₄ and N₂O were utilized. Contractual instruments (e.g., renewable energy credits or renewable power purchase agreements) are not included in Scope 2 emissions. 11 Product-related emissions include Scope 3 emissions from products manufactured in operated Refining assets and NGL fractionators. Our products include jet fuel, gasoline, diesel, fuel oil, petroleum coke, NGLs and other products. The data in this report assumes that all fuels are 100% combusted by the end user for purposes of calculating Scope 3 Category 11 emissions. Non-fuels products, such as sulfur, are not combusted by the end user and therefore are not included in these Scope 3 estimates. For U.S. assets, GHG emissions are calculated using the EPA factors identified in Table MM-1 of 40 CFR Part 98 as of March 2020. GHG emissions for NGL fractionators are calculated using the EPA factors identified in Table NN-1 of 40 CFR Part 98 as of March 2020. All Phillips 66 NGL fractionators are in the United States. For European assets, GHG emissions are calculated using U.K. Government Conversion Factors for GHG emissions as of July 2020. 12 Manufacturing-related intensity is calculated as Scope 1 and 2 metric tons of CO₂e divided by processed inputs. Processed inputs include feedstocks, primarily crude and NGLs, processed in operated global Refining, Excel Paralubes and NGL fractionators. Product-related intensity is calculated as Scope 3 from Use of Sold Products metric tons of CO₂e divided by total products produced. Total products produced include all refined petroleum products, combusted and not combusted by the end user, and NGLs fractionated at our operated assets. Products moved through pipelines and terminals are excluded. 13 Environmental events are those that result in an exceedance of the permit or regulatory-based numeric emissions limit, or a significant release of hydrocarbon or chemical. The count is of events that require immediate agency notifications. 14 Spills represent liquid hydrocarbons from operating assets that reach land or water and are >1 bbl. 15 More than 80% of 2021 spills due to 2 incidents. Lessons learned have been shared widely across the organization. 16 Spills beyond secondary containment; includes free product recovered; does not include remediated soil. 17 Midstream liquid hydrocarbon spills outside primary containment. 18 Includes free product recovered; does not include remediated soil. 19 Refining only. 20 Freshwater is defined as water that has low salinity – usually less than 0.1% (local legal definitions vary). The reported value includes freshwater used as once-through cooling water. Water recycle practices are prevalent within Phillips 66, and result in reduced water withdrawn. Examples include reuse of intermediate refinery streams and optimization of cooling tower and boiler systems to improve water use efficiency. 21 The World Resources Institute Aqueduct™ Water Risk Atlas is used to identify areas with high water demand or potential for water scarcity in the future. Sites are classified as water scarce if withdrawing and consuming water in locations with High (40%-80%) or Extremely High (>80%) Baseline Water Stress as classified by the Aqueduct™ Water Risk Atlas. Water use in water scarce areas is expressed as a percentage of the total freshwater use. 22 1000 bbls of water per 1000 bbls of processed inputs. 23 Water consumed is primarily due to evaporative losses (e.g., operation of cooling towers). 24 Water that has been treated to meet National Pollutant Discharge Elimination System permits. 25 A minority of sites use once-through cooling towers and these sites operate to achieve a high percentage of non-freshwater usage. 26 Includes Refining, Midstream and Lubricant facilities. 27 Includes refinery process catalyst captured for metals reclamation, such as metal, glass and paper from other business units. 28 E-waste recycled includes all electronic-waste avoiding landfills by being refurbished or recycled. 29 Soybean oil, canola oil and corn oil, used cooking oil and tire pyrolysis oil. 30 Total combustion energy is imported electricity, site-generated electricity (cogeneration plants) and imported steam for all operated assets. 31 Electricity exported to the grid and third parties from cogeneration plants at our refineries. 32 Power consumed is from imported electricity and site-generated electricity from cogeneration plants. 33 Energy Intensity ratio for operated assets. 34 New disclosure in 2021. Data are based on inspection frequency requirements in 49 CFR 195.452. The plan covers 19.3% of hazardous liquid pipelines. Non-regulated pipelines are excluded. 35 New disclosure in 2021. Active and operated pipelines near ecologically sensitive areas as defined by Pipeline and Hazardous Materials Safety Administration (PHMSA). Pipelines may not actually intersect or cross sensitive areas. 36 Data represents our global workforce and includes Sentinel Transportation, LLC, unless otherwise noted. 37 U.S. workforce. 38 Retention rate based on voluntary resignations. 39 Schools include primary, secondary, trade, technical and universities. 66 PHILLIPS 66 2022 SUSTAINABILITY REPORT

Philips 66 ESG Report Page 67 Page 69

Philips 66 ESG Report Page 67 Page 69