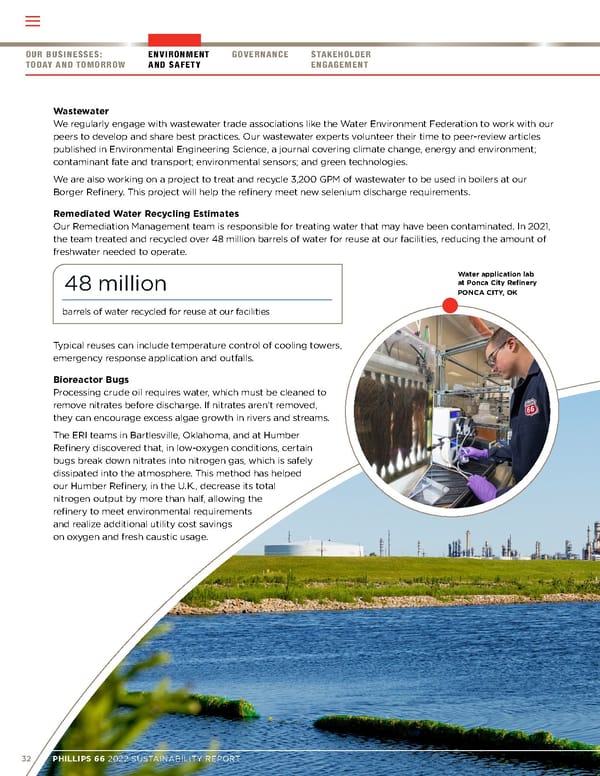

Wastewater We regularly engage with wastewater trade associations like the Water Environment Federation to work with our peers to develop and share best practices. Our wastewater experts volunteer their time to peer-review articles published in Environmental Engineering Science, a journal covering climate change, energy and environment; contaminant fate and transport; environmental sensors; and green technologies. We are also working on a project to treat and recycle 3,200 GPM of wastewater to be used in boilers at our Borger Refinery. This project will help the refinery meet new selenium discharge requirements. Remediated Water Recycling Estimates Our Remediation Management team is responsible for treating water that may have been contaminated. In 2021, the team treated and recycled over 48 million barrels of water for reuse at our facilities, reducing the amount of freshwater needed to operate. Typical reuses can include temperature control of cooling towers, emergency response application and outfalls. Bioreactor Bugs Processing crude oil requires water, which must be cleaned to remove nitrates before discharge. If nitrates aren’t removed, they can encourage excess algae growth in rivers and streams. The ERI teams in Bartlesville, Oklahoma, and at Humber Refinery discovered that, in low-oxygen conditions, certain bugs break down nitrates into nitrogen gas, which is safely dissipated into the atmosphere. This method has helped our Humber Refinery, in the U.K., decrease its total nitrogen output by more than half, allowing the refinery to meet environmental requirements and realize additional utility cost savings on oxygen and fresh caustic usage. 48 million barrels of water recycled for reuse at our facilities 32 PHILLIPS 66 2022 SUSTAINABILITY REPORT Water application lab at Ponca City Refinery PONCA CITY, OK PHILLIPS 66 2022 SUSTAINABILITY REPORT OUR BUSINESSES: TODAY AND TOMORROW ENVIRONMENT AND SAFETY GOVERNANCE STAKEHOLDER ENGAGEMENT

Philips 66 ESG Report Page 33 Page 35

Philips 66 ESG Report Page 33 Page 35