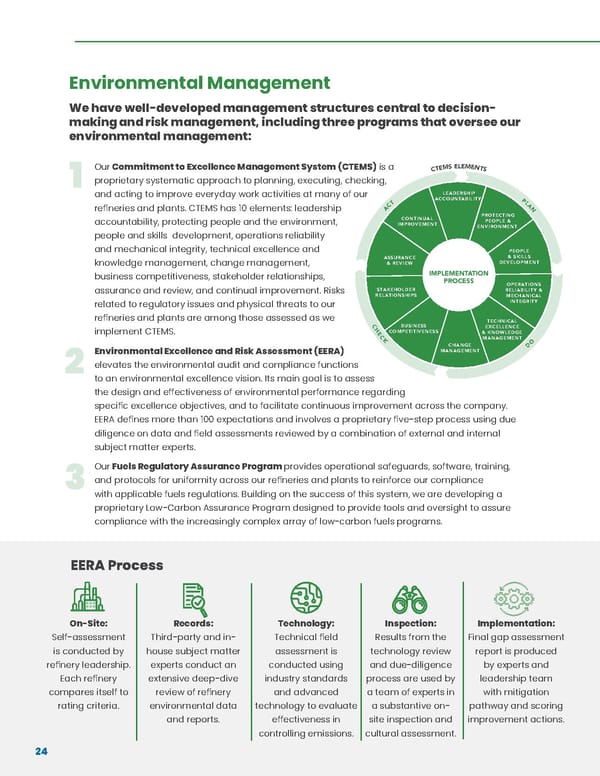

24 Our Commitment to Excellence Management System (CTEMS) is a proprietary systematic approach to planning, executing, checking, and acting to improve everyday work activities at many of our refineries and plants. CTEMS has 10 elements: leadership accountability, protecting people and the environment, people and skills development, operations reliability and mechanical integrity, technical excellence and knowledge management, change management, business competitiveness, stakeholder relationships, assurance and review, and continual improvement. Risks related to regulatory issues and physical threats to our refineries and plants are among those assessed as we implement CTEMS. Environmental Excellence and Risk Assessment (EERA) elevates the environmental audit and compliance functions to an environmental excellence vision. Its main goal is to assess the design and effectiveness of environmental performance regarding specific excellence objectives, and to facilitate continuous improvement across the company. EERA defines more than 100 expectations and involves a proprietary five-step process using due diligence on data and field assessments reviewed by a combination of external and internal subject matter experts. Our Fuels Regulatory Assurance Program provides operational safeguards, software, training, and protocols for uniformity across our refineries and plants to reinforce our compliance with applicable fuels regulations. Building on the success of this system, we are developing a proprietary Low-Carbon Assurance Program designed to provide tools and oversight to assure compliance with the increasingly complex array of low-carbon fuels programs. 1 2 3 Environmental Management We have well-developed management structures central to decision- making and risk management, including three programs that oversee our environmental management: EERA Process LEADERSHIP ACCOUNTABILITY PROTECTING PEOPLE & ENVIRONMENT PEOPLE & SKILLS DEVELOPMENT OPERATIONS RELIABILITY & MECHANICAL INTEGRITY TECHNICAL EXCELLENCE & KNOWLEDGE MANAGEMENT CHANGE MANAGEMENT BUSINESS COMPETITIVENESS STAKEHOLDER RELATIONSHIPS ASSURANCE & REVIEW CONTINUAL IMPROVEMENT C T E M S E L E M E N T S P L A N A C T C H E C K D O IMPLEMENTATION PROCESS C T E M S E L E M E N T S On-Site: Self-assessment is conducted by refinery leadership. Each refinery compares itself to rating criteria. Records: Third-party and in- house subject matter experts conduct an extensive deep-dive review of refinery environmental data and reports. Technology: Technical field assessment is conducted using industry standards and advanced technology to evaluate effectiveness in controlling emissions. Inspection: Results from the technology review and due-diligence process are used by a team of experts in a substantive on- site inspection and cultural assessment. Implementation: Final gap assessment report is produced by experts and leadership team with mitigation pathway and scoring improvement actions. 24

Valero ESG Report Page 23 Page 25

Valero ESG Report Page 23 Page 25