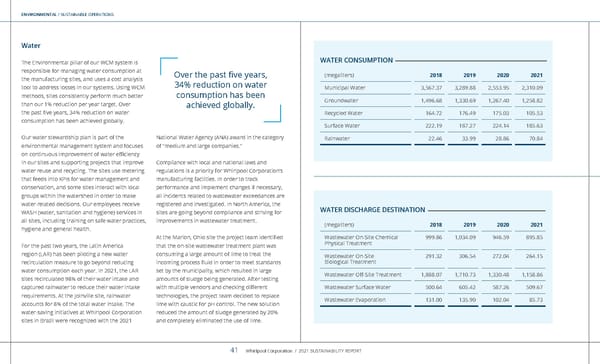

ENVIRONMENTAL / OUR ESG APPROACH ENVIRONMENTAL / SUSTAINABLE OPERATIONS Water The Environmental pillar of our WCM system is responsible for managing water consumption at the manufacturing sites, and uses a cost analysis tool to address losses in our systems. Using WCM methods, sites consistently perform much better than our 1% reduction per year target. Over the past five years, 34% reduction on water consumption has been achieved globally. Our water stewardship plan is part of the environmental management system and focuses on continuous improvement of water efficiency in our sites and supporting projects that improve water reuse and recycling. The sites use metering that feeds into KPIs for water management and conservation, and some sites interact with local groups within the watershed in order to make water-related decisions. Our employees receive WASH (water, sanitation and hygiene) services in all sites, including training on safe water practices, hygiene and general health. For the past two years, the Latin America region (LAR) has been piloting a new water recirculation measure to go beyond reducing water consumption each year. In 2021, the LAR sites recirculated 98% of their water intake and captured rainwater to reduce their water intake requirements. At the Joinville site, rainwater accounts for 8% of the total water intake. The water-saving initiatives at Whirlpool Corporation sites in Brazil were recognized with the 2021 National Water Agency (ANA) award in the category of “medium and large companies.” Compliance with local and national laws and regulations is a priority for Whirlpool Corporation’s manufacturing facilities. In order to track performance and implement changes if necessary, all incidents related to wastewater exceedances are registered and investigated. In North America, the sites are going beyond compliance and striving for improvements in wastewater treatment. At the Marion, Ohio site the project team identified that the on-site wastewater treatment plant was consuming a large amount of lime to treat the incoming process fluid in order to meet standards set by the municipality, which resulted in large amounts of sludge being generated. After testing with multiple vendors and checking different technologies, the project team decided to replace lime with caustic for pH control. The new solution reduced the amount of sludge generated by 20% and completely eliminated the use of lime. Over the past five years, 34% reduction on water consumption has been achieved globally. WATER CONSUMPTION WATER CONSUMPTION (megaliters) 2018 2019 2020 2021 Municipal Water 3,567.37 3,289.88 2,553.95 2,310.09 Groundwater 1,496.68 1,330.69 1,267.40 1,258.82 Recycled Water 164.72 176.49 175.03 105.53 Surface Water 222.19 187.27 224.14 185.63 Rainwater 22.46 33.99 28.86 70.84 WATER CONSUMPTION WATER DISCHARGE DESTINATION (megaliters) 2018 2019 2020 2021 Wastewater On-Site Chemical Physical Treatment 999.86 1,034.09 946.59 895.85 Wastewater On-Site Biological Treatment 291.32 306.54 272.04 264.15 Wastewater Off-Site Treatment 1,888.07 1,710.73 1,330.48 1,158.86 Wastewater Surface Water 500.64 605.42 587.26 509.67 Wastewater Evaporation 131.00 135.90 102.04 85.73 Whirlpool Corporation / 2021 SUSTAINABILITY REPORT 41 Whirlpool Corporation / 2021 SUSTAINABILITY REPORT 41

Whirlpool Sustainability Report Page 40 Page 42

Whirlpool Sustainability Report Page 40 Page 42