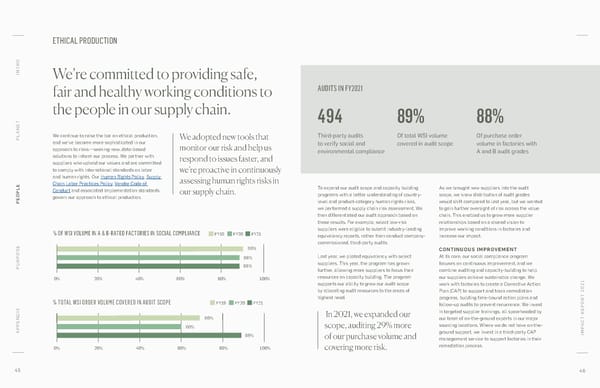

ETHICAL PRODUCTION O INTR We’re committed to providing safe, fair and healthy working conditions to AUDITS IN FY2021 the people in our supply chain. 494 89% 88% ANET We continue to raise the bar on ethical production, We adopted new tools that Third-party audits Of total WSI volume Of purchase order PL and we’ve become more sophisticated in our to verify social and covered in audit scope volume in factories with approach to risks—seeking new, data-based monitor our risk and help us environmental compliance A and B audit grades solutions to inform our process. We partner with respond to issues faster, and suppliers who uphold our values and are committed to comply with international standards on labor we’re proactive in continuously and human rights. Our Human Rights Policy, Supply assessing human rights risks in Chain Labor Practices Policy, Vendor Code of To expand our audit scope and capacity building As we brought new suppliers into the audit Conduct and associated implementation standards OPLE govern our approach to ethical production. our supply chain. programs with a better understanding of country- scope, we knew distribution of audit grades PE level and product-category human rights risks, would shift compared to last year, but we wanted we performed a supply chain risk assessment. We to gain further oversight of risk across the value then differentiated our audit approach based on chain. This enabled us to grow more supplier those results. For example, select low-risk relationships based on a shared vision to % OF WSI VOLUME IN A & B-RATED FACTORIES IN SOCIAL COMPLIANCE suppliers were eligible to submit industry-leading improve working conditions in factories and FY19 FY20 FY21 equivalency reports, rather than conduct company- increase our impact. commissioned, third-party audits. 90% CONTINUOUS IMPROVEMENT 88% Last year, we piloted equivalency with select At its core, our social compliance program PURPOSE 88% suppliers. This year, the program has grown focuses on continuous improvement, and we further, allowing more suppliers to focus their combine auditing and capacity-building to help 0% 20% 40% 60% 80% 100% resources on capacity building. The program our suppliers achieve sustainable change. We supports our ability to grow our audit scope work with factories to create a Corrective Action by allocating audit resources to the areas of Plan (CAP) to support and track remediation T 2021 % TOTAL WSI ORDER VOLUME COVERED IN AUDIT SCOPE highest need. progress, building time-bound action plans and FY19 FY20 FY21 follow-up audits to prevent recurrence. We invest In 2021, we expanded our in targeted supplier trainings, all spearheaded by T REPOR 69% our team of on-the-ground experts in our major C 60% scope, auditing 29% more sourcing locations. Where we do not have on-the- A APPENDIX APPENDIX 89% of our purchase volume and ground support, we invest in a third-party CAP IMP management service to support factories in their 0% 20% 40% 60% 80% 100% covering more risk. remediation process. 45 46

Williams-Sonoma, Inc - Impact Report Page 22 Page 24

Williams-Sonoma, Inc - Impact Report Page 22 Page 24