Applied Materials Sustainability Report

SUSTAINABILITY REPORT 2021 Make Possible ® a Better Future

INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS Applied Materials has the industry’s broadest and most enabling portfolio of materials engineering solutions used to produce virtually every chip and advanced display in the world. We recognize that this unique leadership position comes with tremendous responsibility to our employees, customers and society. In fiscal 2021, as the world continued to adapt to the impacts of COVID-19 and global supply chain disruptions challenged the resilience of every industry, Applied made strong progress toward our 10-year sustainability roadmap. Our comprehensive 2030 strategy considers the magnitude of our opportunities including social and environmental impacts in our operations (1X), how we work with customers and suppliers (100X), and how our technology can be used to advance sustainability on a global scale (10,000X). Here are just a few highlights of our recent progress: > Reduced our Scope 1 and 2 emissions and increased our use of renewable electricity, remaining on track to achieve our 2030 goals. > Quantified our full Scope 3 emissions inventory for our 2019 baseline and reported our carbon impact and risks in-line with the Task Force on Climate Related Financial Disclosures (TCFD). > Advanced our 3x30 and SuCCESS2030 goals, including accelerating sustainable innovation, improving the longevity of our products, and enabling our suppliers to better meet our ESG expectations. > Strengthened our Culture of Inclusion by providing comprehensive diversity training to all senior leaders and a majority of employees worldwide and increased the representation of women and underrepresented minorities in our company—though we know we have to do much more to reach our targets. > Conducted our first human rights salience assessment, which builds on our Human Rights Statement of Principles . We will report on our progress toward these topics in future years. > Completed an equity audit of our community involvement and investments, and committed to put equity at the center of all future community engagements. In this 2021 Sustainability Report, you will learn how we lead with purpose and support our local communities; invest in people to create a vibrant culture of inclusion where every Applied employee is empowered to grow and thrive in their careers; protect our planet by reducing our direct and indirect impacts; and innovate for progress across our global supply chain. The opportunity for technology to shape a more equitable and sustainable world has never been more promising. Applied Materials remains steadfast in our commitment to work across this ecosystem to drive critical advances that will accelerate a sustainable and inclusive digital economy and Make Possible ® a Better Future for all generations to come. Gary E. Dickerson President and Chief Executive Officer Digital transformation is accelerating and impacting virtually every area of life and the economy. Semiconductors that power this transformation are more essential than ever and greatly influence the prospect of shaping a more sustainable and equitable future. Message from our CEO Sustainability Report 2021 2 INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS

INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS Sustainability Report 2021 3 Applied Materials is the leader in materials engineering solutions used to produce virtually every new chip and advanced display in the world. Our expertise in modifying materials at atomic levels and on an industrial scale enables customers to transform possibilities into reality. We are driven to Make Possible a Better Future for everyone. About Applied Materials Sustainability Report 2021 Our Products and Services Applied provides manufacturing equipment, services, and software to the semiconductor, display, and related industries. Our customers include manufacturers of semiconductor chips, liquid crystal display (LCD) and organic light-emitting diode (OLED) displays, and other electronic devices. Semiconductor Systems Designing and manufacturing the systems used to fabricate semiconductor chips. Applied Global Services Providing consulting, spare parts, services, and automation software to improve equipment and fab operation performance and productivity. Display and Adjacent Markets Making the products to manufacture LCDs, OLEDs, and other display technologies and customer-oriented devices, and equipment for processing flexible substrates. Applied Ventures, LLC Applied Ventures, LLC, is the venture capital arm of Applied Materials, investing in and collaborating with startups pioneering innovations in smartphones, augmented and virtual reality, artificial intelligence, driverless cars, big data, life sciences, 3D printing, robotics, cleantech, and advanced materials. Applied Ventures is stage agnostic and may invest up to $50M per year globally. INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS

Sustainability Report 2021 4 FY21 Company Overview Highlights Awards and Recognition Fortune The World’s Most Admired Companies 2022 JUST100 America’s Most Just Companies 2022 Barron’s Top 100 Most Sustainable Companies 2021 Forbes World’s Best Employers 2021 Investor’s Business Daily Best ESG Companies 2021 Forbes Green Growth 50 List 2021 FTSE4Good CommonWealth Magazine’s Excellence in Corporate Social Responsibility Award, Foreign Enterprise Category, 2021 HEADQUARTERED IN CALIFORNIA’S SILICON VALLEY $ 23.1 B REVENUE ~15,700 PATENTS AMAT STOCK LISTING ON NASDAQ $ 2.5 B R&D INVESTMENT ~27,000 REGULAR FULL-TIME EMPLOYEES WORLDWIDE (>115 LOCATIONS, 19 COUNTRIES) INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS 2022 Human Rights Campaign Best Places to Work for LGBTQ Equality

INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS Sustainability Report 2021 5 We take a holistic approach to sustainability that considers our direct impact and how we run our business (1X), our industry’s impact and that of our customers and suppliers (100X), and how our technology can be used to advance sustainability on a global scale (10,000X). To advance our 1X–100X–10,000X strategy, we: Our 1X–100X–10,000X framework is underpinned by aggressive environmental and social impact goals to hold us accountable for progress. See our Purpose , People , Planet , and Progress goals and progress. Our Sustainability Vision and Strategy Lead with purpose through a values-based approach to innovation, decision-making and community action. Read more Invest in people to build a deep-rooted Culture of Inclusion and foster a diverse and skilled talent pipeline. Read more Innovate for progress to empower transformative innovation that improves technology in harmony with resources. Read more Protect our planet by respecting the Earth’s finite resources while enabling infinite growth in our business and the data economy. Read more INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS

INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS Lead with Purpose Invest in People Protect our Planet Innovate for Progress 10,000 X 100X FOR THE INDUSTRY 1 X FOR OUR BUSINESS FOR THE WORLD Sustainability Report 2021 6 Make Possible a Better Future Empowering a more sustainable and equitable world. INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS

INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS Sustainability Report 2021 7 Our Progress at a Glance In 2021, Applied Materials made progress toward its vision to Make Possible a Better Future. Here are just a few of the highlights. Lead with purpose Invest in people Innovate for progress Protect our planet $ 13.7 M DIRECT CORPORATE CONTRIBUTIONS & FOUNDATION GRANTS ACHIEVED OUR GOAL TO INCREASE WOMEN’S REPRESENTATION IN THE U.S. TO 21% ENGAGED NEARLY 16,000 EMPLOYEES IN THE PATHWAY LEARNING & DEVELOPMENT PROGRAM 2019 SCOPE 3 BASELINE CALCULATED: ~ 12 M MT CO 2 E OF THE APPLIED LEADERSHIP GROUP COMPLETED OUR INCLUSIVE LEADERSHIP TRAINING PROGRAM OF TOOLS UNDER CONTRACT ARE CONTINUOUSLY REFURBISHED, EXTENDING THEIR PRODUCTIVE LIVES RENEWABLE ELECTRICITY USE INCREASED IN THE U.S. AND GLOBAL LY FROM 2020 TO 2021 28% REDUCTION IN SCOPE 1 & 2 MARKET-BASED EMISSIONS 3 X 30 COLLABORATING WITH MULTIPLE CUSTOMERS TO SIGNIFICANTLY REDUCE ENERGY USE & THE IMPACT OF CHEMICAL CONSUMPTION IN THE SEMICONDUCTOR INDUSTRY ADVOCATED FOR ECONOMIC INCENTIVES TO STRENGTHEN THE U.S. SEMICONDUCTOR INNOVATION ECOSYSTEM 87 % 4 1 % 80 % 37 % 5 7 % U.S. GLOBAL 70 % INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS

INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS Sustainability Report 2021 8 To strengthen our focus and improve our performance on potential environmental, social, and governance issues, Applied conducted a corporate responsibility materiality* assessment in 2021 using the Datamaran platform. Corporate Responsibility Materiality Assessment This automated solution helped us comprehensively review a wide range of environmental, social and governance (ESG) topics to identify those ESG issues most important to our stakeholders and where Applied may effect the most significant progress to Make Possible a Better Future. To ensure the most comprehensive identification of relevant issues, the assessment analyzed impacts using a double-materiality lens: assessing ESG factors likely to impact Applied as well as factors that our activities may impact. The assessment includes insights from key stakeholders, including customers, investors, suppliers, policy makers, regulators, media, industries and peers, as well as internal Applied stakeholders. All the issues identified as critical in the matrix are discussed in this report. Though this exercise has affirmed the company’s prioritization of ESG issues that are most strategic and impactful for Applied, such as climate change, energy, supply chain resilience, diversity and inclusion, and human rights, Applied will continue to reassess relative priorities, which may shift in the future. * Materiality in this context and in this report refers to the relative significance of ESG issues in the context of our ESG program, and does not refer to the concept of materiality used in financial reporting, securities, or other applicable law. Importance to Stakeholders Importance to Business H I G HER H I G HER L O WER L O WER Innovation & Technology Community Relations Water & natural capital Employee health & safety Supply chain resilience Public health risk Climate change & GHG emissions Energy management Transition to renewable & alternative energies Management of the Legal & Regulatory Environment Responsible consumption & production Customer privacy & data security Ethical corporate behavior Human rights Workforce management Environmental Social Economic/Governance Waste & hazardous materials management Employee diversity & inclusion INTRODUCTION Message from our CEO About Applied Materials Our Sustainability Vision and Strategy Make Possible a Better Future Our Progress at a Glance Corporate Responsibility Materiality Assessment PURPOSE PEOPLE PLANET PROGRESS

Sustainability Report 2021 9 Lead with Purpose Our values guide every decision we make and every action we take to Make Possible a Better Future for our employees, customers, partners, and neighbors. INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 10 In 2021, the continuing pandemic, historic global supply chain disruptions, increasing impacts of climate change and social inequities, and growing geopolitical unrest challenged nearly all aspects of society and businesses. At the same time, the transformation to a digital economy continued to accelerate at breakneck speed, tightening pressure on the semiconductor industry to scale at an unprecedented pace. As the global leader in materials engineering, Applied Materials is uniquely positioned to drive significant, meaningful, and lasting environmental and social impact across the world. We recognize this position comes with tremendous responsibility and accountability to our employees, customers, partners, investors, and society. Applied takes a strong stance on corporate governance, holding ourselves to high standards of ethics and integrity, privacy, and data security. Throughout 2021, we continued a systematic review and sharpening of our governance policies and procedures to protect our business and stakeholders amid evolving global threats. We engaged leaders, operators, and employees in dedicated trainings and learning opportunities to reinforce awareness, understanding, and compliance across our organizations and geographies. Our purpose extends to uplifting the communities where we live and work as we aim to create a more just, fair, and humane world. In 2021, we engaged a third-party partner to conduct an equity audit of our community involvement and investments to identify and proactively address unintentional barriers arising from bias, norms, or systemic structures. Building on the outcomes of this audit, we made a public declaration to center our community investments in equity, evolving how we approach grantmaking, employee engagement, and personal and professional development. Leading with purpose means putting our core values at the center of our actions and decisions as we Make Possible a Better Future. Lead with Purpose KEY HIGHLIGHTS > Committed to put equity at the center of Applied’s community involvement > Awarded nearly $13.7 million in direct corporate contributions and Applied Materials Foundation grants > Raised $3.8 million for Fight Against Hunger—including $1.9 million raised by Applied employees > Advocated for economic incentives to strengthen the U.S. semiconductor innovation ecosystem > Established regional compliance committees across Applied’s global operations > Refined our privacy policies and procedures in accordance with evolving global privacy laws Sustainability Report 2021 10 INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

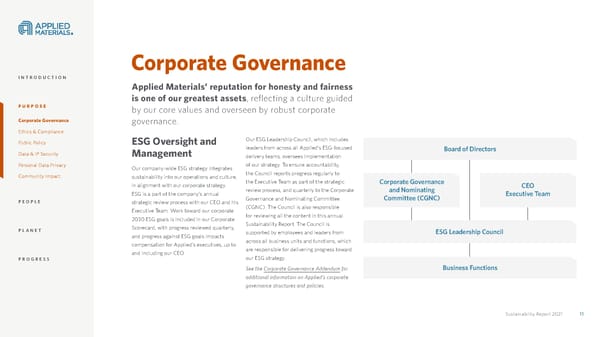

Sustainability Report 2021 11 Sustainability Report 2021 11 Applied Materials’ reputation for honesty and fairness is one of our greatest assets , reflecting a culture guided by our core values and overseen by robust corporate governance. Corporate Governance ESG Oversight and Management Our company-wide ESG strategy integrates sustainability into our operations and culture, in alignment with our corporate strategy. ESG is a part of the company’s annual strategic review process with our CEO and his Executive Team. Work toward our corporate 2030 ESG goals is included in our Corporate Scorecard, with progress reviewed quarterly, and progress against ESG goals impacts compensation for Applied’s executives, up to and including our CEO. Our ESG Leadership Council, which includes leaders from across all Applied’s ESG-focused delivery teams, oversees implementation of our strategy. To ensure accountability, the Council reports progress regularly to the Executive Team as part of the strategic review process, and quarterly to the Corporate Governance and Nominating Committee (CGNC). The Council is also responsible for reviewing all the content in this annual Sustainability Report. The Council is supported by employees and leaders from across all business units and functions, which are responsible for delivering progress toward our ESG strategy. See the Corporate Governance Addendum for additional information on Applied’s corporate governance structures and policies. Board of Directors Business Functions CEO Executive Team Corporate Governance and Nominating Committee (CGNC) ESG Leadership Council INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 12 Sustainability Report 2021 12 Environmental, Social, and Governance (ESG): On a quarterly basis, our Corporate Governance and Nominating Committee (CGNC) receives in-person and written updates from our head of ESG, Corporate Sustainability, and Reporting. The CGNC also reviews the company’s ESG strategy on a regular basis. Environmental Health and Safety (EHS): On a quarterly basis, the CGNC receives updates from our head of EHS, as well as more in-depth annual updates on sustainability, environment, health and safety. Supply Chain and Conflict Minerals: Our Board reviews material supply chain issues and the Board’s Audit Committee reviews the annual Conflict Minerals Report we file with the SEC. Our People and Workplace: The Board’s Human Resources and Compensation Committee (HRCC) oversees corporate culture and human capital management programs, including our Culture of Inclusion practices and initiatives. Community Engagement: Much of our community engagement and grantmaking is led by the Applied Materials Foundation, which has its own board and is independently audited on an annual basis. Applied Materials corporate governance documents are publicly available here . Our 2022 Proxy Statement is available here . Reporting on our ESG efforts is segmented by focus area: INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 13 Sustainability Report 2021 13 Each member of our workforce plays a part in this commitment by conducting their professional duties with responsibility and integrity, and we expect our executives and managers to lead by example. To continually reinforce integrity across our culture, Applied maintains a Global Ethics and Compliance Program with strong leadership and engagement from senior management. Our Board’s Audit Committee oversees the program’s overall design and implementation, including mechanisms for reporting potential violations of law or policy and investigating potential integrity violations by executive officers. The Audit Committee receives quarterly reports covering investigations, program development initiatives, and key trends and indicators. Employee engagement efforts include ethics training, awareness campaigns, and our annual Responsibility and Integrity Week, along with employee ethics surveys and road shows. Throughout our business units, designated Compliance Champions promote ethics and compliance, intellectual property protection and mandatory training completion, and serve as trusted local contacts employees can approach with questions or concerns. In 2021, we established regional compliance committees across our global operations, comprised of local leaders from the Legal and Compliance Organization (LCO), Finance, HR, and business units. These committees enable local implementation of initiatives, provide regional feedback and recommendations, and further drive our culture of integrity. In 2022, we are launching a cross-functional Global Compliance Oversight Committee (GCOC) to enable the business with global compliance procedures, training and controls calibrated to Applied’s business and evolving risk profile. Sponsored by our Chief Legal Officer, Chief Financial Officer, and Chief Human Resources Officer, the GCOC includes senior representatives from each Applied business unit and department and meets quarterly. In 2022, we aim to complete our compliance management systems documentation, which details regional, global and cross-functional compliance policies and procedures. See the Corporate Governance Addendum for additional details about our ethics policies and governance structures. Click here for information on our mechanisms for reporting ethics concerns. Applied is committed to being a good corporate citizen and a trusted partner to our customers, suppliers and shareholders. Ethics and Compliance INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 14 Standards of Business Conduct Applied Materials’ Standards of Business Conduct communicate our values, set expectations for our global workforce and network of trusted partners, and provide guidance designed to promote the highest ethical standards in our interactions with customers, suppliers, colleagues, communities and other stakeholders. The Standards are designed to promote trust in management’s commitment to our values, empower employees to speak up without fear of retaliation, and provide comprehensive guidance about risks, laws, policies and reporting processes, including key concerns such as conflicts of interest, bribery and corruption. Over the past two years we’ve been working on updates to our Standards and associated policies, procedures, controls and trainings, tying them closer to our core values and emphasizing relevance to today’s dynamic risk environment, everywhere we do business. We will complete our Standards update in 2022, along with the release of a new set of standards for business partners. In 2021, we updated our global Anti-Corruption Policy and our Gifts, Meals, Entertainment and Travel (GMET) Policy. We also updated our Conflict of Interest (COI) new-hire process and added anti-corruption controls to our intern recruitment process. To enable real-time data analytics and insights regarding compliance with our Standards, we maintain a global dashboard for tracking conflict-of-interest disclosures, corporate donation approval requests and GMET approvals. We are currently in the process of building out and automating key elements of our third-party anti-corruption due diligence procedures, and in 2021 we transitioned to conducting regular third-party audits. Our Core Values Most valued partner Winning team Responsibility and integrity World-class performance Sustainability Report 2021 14 INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 15 Sustainability Report 2021 15 Responsible Business Alliance Code of Conduct Applied Materials sets clear expectations for social responsibility in our supply chain, requiring our vendors and suppliers to comply with both our own Standards and the Responsible Business Alliance (RBA) Code of Conduct. The RBA Code provides standards related to labor, health and safety, environment, ethics and management systems, including responsible minerals sourcing. Ethics Compliance and Training Applied Materials provides all our employees with training and reinforcement to support their ongoing obligations around ethics and compliance. Newly hired employees are assigned a Standards of Business Conduct training and certification course that covers our policies on conflicts of interest, intellectual property protection, anti-corruption, gifts, insider trading, supplier selection and treatment, speaking up and non-retaliation. Employees renew their training and certification to the Standards each year. Employees also have access to ongoing training in specific areas of ethics and compliance. In 2021, those included live localized anti-corruption training across our APAC region and micro-learning and awareness campaigns designed to provide process refreshers and support ethical decision-making. Responsibility and Integrity Week In April 2022, we held our annual Responsibility & Integrity Week to show Applied’s values in action. Conducted virtually, the week included events designed to raise awareness of themes, resources and best practices supporting our core value of Responsibility and Integrity, and featured insights from regional leaders and a fireside chat with Chief Legal Officer Teri Little and CFO Brice Hill. Over the course of the week, the programming attracted over 38,560 views and included cross-functional presenters from across our teams. In early 2022, we launched a new Inside Compliance channel on our internal Applied4You social media platform. INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Throughout 2021, Government Affairs engaged on proposed changes to corporate and international tax policy to ensure a level playing field for Applied in all the jurisdictions where we operate. We also dedicated considerable effort to proposed U.S. economic incentives to strengthen the U.S. semiconductor innovation ecosystem. Other policy areas of focus included the ongoing pandemic response, international trade, technology regulation, Research and Development (R&D), human resources and labor, and sustainability. These include advocating for immigration reform that embraces the valuable role of immigrants in the U.S. economy; advocating for fairness, diversity and inclusion, including LGBTQ rights; and working on policies, partnerships and R&D incentives to develop and advance next-generation technologies. Sustainability Report 2021 16 Sustainability Report 2021 16 Public Policy Applied Materials participates in efforts to inform policymakers about issues and challenges critical to our company, our customers and our end users, typically via meetings, hearings and trade association advocacy efforts. INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 17 Sustainability Report 2021 17 Business and Trade Associations Applied Materials maintains memberships in various business and trade associations that advance issues aligned with our corporate strategy and the needs of our company, industry, employees, and communities. Our membership in a group does not imply that we endorse the entirety of that group’s policy positions. In 2021, Applied paid approximately $578,000 in trade association membership dues, 18% of which were specified by the associations as non-deductible lobbying expenditures. This total does not include conference or event sponsorships, programming activities or similar costs. Applied Materials reports on federal lobbying through the Lobbying Disclosure Act Database, and files periodic reports with federal and state agencies as appropriate. Our U.S. Trade and Business Associations membership list can be found here . Political Contributions The Applied Materials, Inc. Political Action Committee (AMPAC) contributes to federal candidates, political action committees and party committees supporting issues of strategic importance to Applied, consistent with all legal requirements. Our State Contributions Committee oversees corporate political spending to advance those strategic issues at the state and local levels. While Applied pays the administrative expenses for AMPAC, AMPAC is funded entirely through voluntary contributions from eligible employees, and does not make any contributions using Applied Materials corporate funds. AMPAC’s activities are overseen, and its contributions reviewed and approved, by the AMPAC Board of Directors. Contributions are based solely on corporate objectives, without regard for the private political preferences of either the employees who contribute to AMPAC or individual committee members. During 2021, political contributions made by AMPAC totaled $24,600. See the Corporate Governance Addendum for additional details on Applied’s political donation policies, mechanisms, and compliance practices. Political Spending FY 2021 FY 2020 FY 2019 POLITICAL CONTRIBUTION DATA Total value of financial contributions to political parties, candidates, and related institutions by Applied Materials $0 $0 $0 Total value of financial contributions to political parties, candidates, and related institutions by AMPAC $24,600 $53,500 $84,000 INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 18 Sustainability Report 2021 18 Recognizing that cyber-attacks long ago moved from being a matter of if to when, we maintain both a robust defense framework and the capacity for rapid detection and response. We conduct 24/7 monitoring and weekly vulnerability assessments and continuously update our mitigation practices to stay ahead of threats. Among other efforts, we: > Maintain response procedures and escalation protocols > Employ third parties for external threat monitoring, penetration testing and phishing exercises > Maintain enhanced email security controls > Provide robust training for our employees on recognizing security threats to enable compliance with applicable data security laws, regulations, industry practice and our internal policies > Partner with industry groups, government agencies and outside experts for information exchange and peer benchmarking > Engage third-party auditors to help assure the effectiveness of internal controls Our efforts extend across our supply chain via enhanced security controls embedded in the supplier onboarding process, protocols for assessing supply chain cyber-breaches and ransomware incidents, a playbook for restoring business continuity and continuous assessment and control enhancement for high-impact suppliers. To enhance customer trust, we provide virus-free certifications with all sales of Applied semiconductor systems. Applied Materials has undergone a National Institute of Standards of Technology (NIST) Cybersecurity Framework assessment and currently maintains one of the best BitSight security scores among our industry peers. We’ve also achieved ISO 27001 certification for information security at 45 of our business sites, in order to align our data security management systems and programs with global best practices. Our Chief Information Security Officer reports at least quarterly to the Board’s Audit Committee on our data and IP security programs, policies, controls, key risks and notable incidents. Applied Materials considers data security one of our top strategic priorities. In a threat landscape highlighted by massive data breaches, rising ransomware attacks, increasing availability of hacking tools and incursions by state-sponsored actors, we devote all necessary resources toward making Applied a safe data choice for our global stakeholders. Data and IP Security INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 19 Sustainability Report 2021 19 We maintain a privacy policy that describes our procedures regarding the collection, use, storage and disclosure of information collected through these channels, and a dedicated email address to streamline questions, concerns and reporting issues around privacy. In 2021, we began a full overhaul and expansion of our policies and procedures to adapt to evolving global privacy laws, including China’s Personal Information Protection Law. We also launched a technology platform to semi-automate the creation and maintenance of records of personal data processing activities and a map of personal data in our systems. Throughout the year, we conducted instructor-led virtual trainings on compliance policies and practices, targeted to: > Roles and responsibilities related to new and updated privacy laws > Human Resources, Information Technology and other functions that process high volumes of personal data > Regional compliance committees, including their most senior country leadership We anticipate rolling out global required trainings for all employees by summer 2022. Applied Materials respects the privacy of all individuals with whom we communicate and interact , whether directly or via our software or website. Personal Data Privacy INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 20 Sustainability Report 2021 20 We turn our values into local action through community engagement efforts driven by our belief that equity-centered engagement contributes to a more just, fair and humane world. We are committed to working collaboratively to address historical inequities and to learning from leaders who understand the issues we hope to help solve. Applied Materials and the Applied Materials Foundation focus funding on nonprofits working to advance education, civic engagement, arts and culture, the environment, and girls’ empowerment—the latter primarily through the Generation Girl® initiative, a signature Foundation program. We also pivot in response to societal need, as we have over the past two years to support community service organizations and first responders during critical periods of the COVID-19 pandemic. At Applied Materials, making a positive contribution to the world around us is the foundation of our culture. We respect each individual, welcome diversity and embrace different perspectives as a key component of innovation—valuing our differences is our greatest strength. Community Impact Breakdown of Contributions by Category “Working at Applied Materials allows me to enjoy all my passions— growing my technical skills and having ownership of projects that drive key business outcomes, while at the same time working with my community and peers through volunteering and outreach opportunities. I love that I can grow and learn in all aspects through Applied’s initiatives, employee groups, and technology experts. Erika Process Engineer $1,299,057 $2,828,701 $3,029,760 $666,942 $962,400 $145,549 $4,794,230 $13,726,640 DISASTER RESPONSE ENVIRONMENT GIRLS’ EMPOWERMENT ARTS & CULTURE EDUCATION CIVIC DEVELOPMENT EMPLOYEE MATCHING TOTAL INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 21 In 2021, Applied Materials and the Foundation awarded $13,726,640 in direct corporate contributions and Foundation grants, benefiting 330 recipients in 10 countries. The total represents a decrease from 2020 as the Foundation’s COVID-19 response downshifted to recovery efforts. At the same time, we enabled our employees to achieve greater impact on community issues through the Foundation’s matching grant program, which doubles individual employee giving up to $3,000 annually— aligning our support behind the causes our people care about. During large, culturally significant celebrations such as Black History Month and Pride Month, our employee communications highlight local and national charities working for social justice and equity, suggesting ways to make a positive impact. We believe our role as leaders is to make the world a better place, and we are committed to taking meaningful action. “I have been both a recipient and supporter of food programs... I am proud to be part of a company that gives back to our communities in such a meaningful way. I am so incredibly grateful for the opportunities I have here at Applied, the position our company is in, and the ability to continue to help others.” Ann Enterprise Enablement Group Community Impact con t. INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 22 Evolving Engagement to Center Equity As part of a multi-year journey to evaluate and improve the Applied Materials Foundation and Applied Materials’ U.S.- based engagement in communities of color, our Community Affairs team partnered with Black-owned consulting firm Frontline Solutions in 2021 to conduct an equity assessment examining Foundation and company programs and practices. The team dedicated time to listening, learning, and reflecting on issues of equity, prejudice, power, and privilege, seeking to identify and proactively address unintentional barriers arising from bias, norms, or systemic structures. We also surveyed recent grantees on the degree to which company and Foundation programs and practices center equity. Based on audit results and feedback, we made a public declaration of commitment to equity-centered community involvement focused across three core areas: > Grantmaking: Applied and the Foundation will make data-driven assessments of how organizations include the voice of the community in the issue they seek to address, to ensure we are funding organizations with the deep community trust required to achieve their goals. To increase transparency, we will post grant recipients of both Foundation and company grants on our website beginning in 2022. > Employee Engagement: The Community Affairs team will work with community leaders, our Employee Resource Groups, and an outside vendor to identify high-impact nonprofits led by and serving people of color to promote a greater variety of volunteer and other community engagement opportunities for Applied employees. > Personal and Professional Development: To ensure that company and Foundation decision-making structures and Community Affairs operations are centered in equity, we will conduct internal team learning activities to address biases and norms that negatively impact communities and organizations of color. 2021 Excellence in Corporate Social Responsibility Award Top 15, Foreign Enterprise Category CommonWealth magazine, Taiwan Sustainability Report 2021 22 INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 23 Sustainability Report 2021 23 Responding to Acute Community Need Applied Materials, the Applied Materials Foundation, and our 27,000 employees remain flexible in providing funding for communities severely impacted by the COVID-19 pandemic, natural disasters, and systemic racism. For the past two-plus years, Applied and the Foundation have stepped up to help those most impacted by the COVID-19 pandemic. These efforts have included providing financial support to U.S. food banks and global relief organizations, delivering Personal Protective Equipment (PPE) and other supplies to frontline medical personnel, providing hand sanitizer to senior programs and homeless shelters, and ensuring disadvantaged children and their families have access to nutritious meals. In 2021, the Foundation partnered with the Indian- American Friendship Alliance to deliver oxygen concentrators to India during that country’s deadly Delta variant surge. As Asian-Americans faced a wave of racist violence across the U.S. inspired by COVID-19 misinformation and anti-Asian rhetoric, the Foundation donated to Asian Americans Advancing Justice to support their efforts to document hate and demand action. In the wake of the February 2021 ice storms that disrupted power grids across Texas, the Foundation provided funding to Caritas of Austin and the American Red Cross to aid community relief efforts. Promoting Civic Development In 2021, the COVID-19 pandemic continued to adversely affect nonprofit organizations and the way they provide services. Applied and the Foundation responded by providing infrastructural support to 94 community organizations, helping them become more efficient and grow their capacity to serve local needs, including through advocating for affordable housing and helping families in need access housing and income assistance. Through joint support from Applied and the Foundation, we hope to prevent families from becoming homeless and to fund supportive services and shelter for those who are already without a home. The following examples illustrate this approach in 2021: > In response to high numbers of homeless youth in Portland, Oregon, and Austin, Texas, the Foundation funded organizations such as New Avenues for Youth and LifeWorks, which help transition homeless youth to stable and safe housing. > In Silicon Valley, the Foundation provided financial support for the expansion of the Sunnyvale Community Services facility. With three times more space, the new building allows improvements in the management and delivery of current services and the opportunity to offer new support services to individuals and families. > In Arizona, the Foundation supported House of Refuge, Inc. and UMOM New Day Centers, Inc., which serve families in transition, provide safe housing and offer wrap-around services that help families become financially stable. > In India, Applied supported SOS Children’s Villages, an organization providing homes, nurturing care and educational support for children who have been abandoned or orphaned. INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 24 Sustainability Report 2021 24 Fight Against Hunger The ongoing COVID-19 pandemic has exacerbated longstanding societal inequities, with historically excluded communities experiencing the most severe impact. In the first year of the pandemic, organizations working to alleviate food insecurity at the community level reported a 100% increase in demand for their services. While demand decreased slightly in 2021, it remained above historical norms, and food banks had to contend with additional pressures from high food and transportation costs, supply chain delays, and a lack of volunteers. To do our part in addressing these challenges, Applied employee teams across North America closed out the year with our annual Fight Against Hunger fundraising effort. During the campaign, which remained primarily virtual to prioritize health and safety, our employees raised $1.9 million, our most generous employee donation total ever. Adding a dollar-for- dollar match from the Applied Materials Foundation, we were able to distribute over $3.8 million to 52 food banks across the U.S. and Canada. Global Fight Against Hunger efforts continued throughout the year, often aligned with cultural and seasonal holidays in different countries. In Belgium, the Netherlands, Japan, and Taiwan, employee efforts benefited food banks. In Greece, our people supported The Smile of the Child’s work providing meals to children living in poverty. In India, employee giving targeted mid-day meals for students through the Akshaya Patra Foundation, as well as year- round support for orphans living in group homes. In China, our people filled and distributed food packages, and in Israel they supported the delivery of meals to Holocaust survivors. All these efforts reflect Applied’s values and purpose, aligning who we are with what matters to our employees and what’s needed in our communities. INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 25 25 Generation Girl ® Initiative In a time of renewed focus on diversity and empowerment across industry and society, the Applied Materials Foundation’s Generation Girl ® initiative continued its efforts to ensure that girls have the opportunity to reach their full potential. The Generation Girl initiative works with nonprofit organizations throughout the United States to help girls gain the confidence, skills, and opportunities they need to succeed. In recognition of the fact that women of color remain the tech industry’s most underrepresented group, the program prioritizes funding for organizations serving Black, Latinx, and Indigenous girls as well as girls from low-income backgrounds. By working to break down societal and systemic barriers and develop talent in underrepresented communities, we can help make our future workplaces more vibrant, equitable and effective. During the grant period that began in September 2020 and ran through August 2021, the Generation Girl initiative provided close to $1 million to 28 nonprofit organizations serving girls in six U.S. regions where Applied maintains facilities, with 89% of funded programs focusing on girls in middle and high school. Foundation funding enabled grantees to deliver virtual, hybrid, and/or in-person after-school and summer programming and connect girls and their caregivers to local community service agencies to address need. All told, grantees were able to serve almost 6,000 girls, 69% of whom identify as Black, Latinx, or Indigenous and 64% of whom come from low-income backgrounds. While girls continued to face barriers to program participation—including cancellation of large in-person events, increased caregiving responsibilities, and virtual learning burnout—impact on the girls served remained strong, with over 75% of participants reporting growth in research- based girls empowerment outcomes, STEM interest, and STEM confidence. T Sustainability Report 2021 INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Throughout 2021, the Foundation continued to facilitate learning through bimonthly meetings of the Community of Practice (CoP), in which representatives from the 30 grantee organizations met virtually to discuss common challenges, share success stories, and pursue partnership opportunities. In 2021, the group focused on the pandemic’s impact on girls, strategies for supporting girls who have experienced trauma, delivering service to hard-to- reach communities and plans to resume in-person services in various regions. All of the participating organizations gave these meetings high marks for fostering collaboration and a community of support during difficult times. Applied employee volunteers remain a vital component to the Generation Girl initiative, teaching girls about careers in the semiconductor industry and inspiring them to dream big. In 2021, Applied employees across the U.S. volunteered more than ever with girl-serving organizations such as the Society of Women Engineers–Santa Clara Valley, GirlStart, Girls on the Run Silicon Valley, Latinitas and the Girls Empowerment Network—conducting virtual career exploration sessions, serving as volunteer mentors, and leading online activities that introduce girls to microchips and more. The virtual environment helped break down regional barriers to volunteerism, connecting women engineers in Montana with high school girls in New Jersey, female technical project managers in Silicon Valley with aspiring coders in Austin, and remote college recruiting staff with young women pursuing computer science degrees across the U.S. In October, employees came together in celebration of International Day of the Girl to listen to leaders from Alliance for Girls and TechBridge Girls speak about the impact of the pandemic on girls in the U.S. They then turned that knowledge into action through participation in a mentorship forum with female high school students participating in the YesSheCan Campaign. A complete list of 2021 Generation Girl initiative grantees is available here . Generation Girl Initiative con t. #ChooseToChallenge In March 2021, Applied Materials employees responded to the year’s International Women’s Day theme #ChooseToChallenge by raising women’s voices and providing resources to help girls become confident leaders and innovators. From the U.S. to India, China, Taiwan, Japan, Korea, Singapore, and Israel, the company, our employees, and our Women’s Professional Development Network Employee Resource Group (ERG) hosted activities such as panel discussions on further cultivating Applied’s Culture of Inclusion, a working mom’s conversation, networking sessions, virtual volunteering opportunities, informational videos telling the stories of women at Applied, and daily stories and calls to action. 26 Sustainability Report 2021 INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 27 27 Promoting Education Access To inspire young minds, prepare the next generation of innovators, and pave the way to more promising futures, Applied Materials and the Applied Materials Foundation work continuously to give students worldwide equitable access to high-quality education. In FY2021, Applied Materials and the Foundation provided $2,828,701 in funding to 63 educational initiatives. Throughout the year, as COVID-19 waves forced many schools to cycle between distance, hybrid and in-person learning, we remained flexible in our funding decisions. We listened to school and community leaders, and Applied and the Foundation jointly provided needed tools to reach kids where they are, address learning loss challenges and bolster teacher enthusiasm. Applied and the Foundation funded programs to address the mental health needs of kids returning to classrooms and supported high- quality STEM education programs so kids from all backgrounds and income levels can envision future careers in technology. Highlights at the local level included: > Flexible support in East San José, California. The Foundation worked closely with school districts and education nonprofits serving the predominantly working-class, immigrant families of East San José, who have been disproportionately impacted by the pandemic. Foundation grantees City Year San José/Silicon Valley and Catholic Charities offered in-person learning pods for children of essential workers and others while most students learned remotely. When schools reopened onsite, these organizations maintained their commitment to student learning through in-school support and after- school enrichment programs. > Professional development for teachers in Austin, Texas. In the Manor Independent School District, the Foundation funded a program that trains teachers in new strategies for equitably and effectively engaging students during distance learning. > Illuminating career pathways in Massachusetts. Foundation grantees including Leap for Education and Gloucester Marine Genomics Institute were able to offer in-person experiential learning and career exploration projects that introduced youth to career pathways while complying with public health guidelines. > Taking science programs online in Korea. Applied expanded our relationship with ChildFund Korea, providing funding to convert experimental science lessons to an online format for distance learning. > Improving online STEM access in Taiwan. Applied supported efforts by the Association of Taiwan Online Education Development to improve access to online STEM programs by creating science experiments and other online resources for 5th to 9th graders, all available free to teachers. Sustainability Report 2021 Austin Partners in Education Recognizes Applied Materials Foundation In Texas, Austin Partners in Education, a nonprofit organization working in partnership with the Austin Independent School District, named the Applied Materials Foundation as its Donor Champion of the Year for 2021, for its support of organizations promoting college readiness. Nicole Wayman, a 26-year Applied employee, was also named Volunteer of the Year for leading efforts to build an outdoor theater for McCallum High School, allowing students to conduct rehearsals and performances, attend lectures, and schedule club meetings safely during the pandemic. INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 28 Sustainability Report 2021 28 Engaging Communities on the Environment Applied’s commitment to the environment goes beyond business practices and policies. Together with the Applied Materials Foundation, we leverage philanthropy to engage youth in the natural world and help communities build a more sustainable future for all. In FY2021, Applied Materials and the Foundation awarded $666,942 in grants to 37 nonprofits in this focus area. Together, Applied and Foundation grantee organizations pursued a mix of environmental advocacy and youth education and outreach activities, many of the latter conducted outdoors or virtually for COVID safety. > In Silicon Valley, the Foundation- supported organization Environmental Volunteers created “Walkable Field Trips,” designed to introduce school classes to nature in city parks and other open spaces without the need to use buses or public transportation. > In Israel, Applied supported an organic vegetable garden on the Pardesanut Museum grounds, which serves as an environmental education classroom for at-risk children. > In Germany, Applied supported the youth-led nonprofit Plant for the Planet in its reforestation work and efforts to teach children and adults about climate change and global justice. > Throughout the year, the Foundation continued to support teacher development in sustainability, urban forestry, citizen science and ecology. Through organizations like the National Wildlife Federation and Wild Basin in Austin, Texas; the Arizona Sustainability Alliance in Tempe, Arizona; and the Flathead Lake Biological Station in Montana, teachers were invited to explore, learn and take back meaningful experiences to their classrooms. In April, Applied’s annual EarthWorks campaign aimed to educate and inspire our global employees about ways to adopt sustainable practices and technologies in their daily lives, homes, and communities. Globally, Applied employees make those messages a reality year-round. INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS

Sustainability Report 2021 29 Sustainability Report 2021 29 Funding Arts and Culture During COVID-19 The COVID-19 pandemic has had a devastating impact on arts organizations whose mission depends heavily on in-person programming. Following a year in which organizations pivoted with varying success to streaming and on-demand programming, 2021 saw many evolving to meet our greater understanding of COVID-19 transmission by offering experiential, often family-oriented and culturally diverse programming in a safer outdoor environment. To support those and other efforts, Applied Materials and the Applied Materials Foundation awarded $1,299,057 in grants to 67 nonprofits. Foundation-funded projects included: > The Waterloo Greenway Creek Show, which transformed a new, 11-acre public greenspace in downtown Austin, TX, through original, light-based artworks designed to evoke the natural environment of Waller Creek, the park’s centerpiece. > Alight on MARS, which transformed the grounds of Gloucester, MA’s Manship Artists Residency and Studios via site-specific sculpture and light works inspired by the area’s threatened firefly population. > The ICA San José (CA) Facade Project, which transformed the face of San José’s contemporary art gallery into art itself via monumental murals and artworks, with initial displays by Iranian-American artist Amir H. Falla and Detroit-based Ghanaian artist Conrad Egyir. > Centuries in the Making, an immersive light and sound installation, brought Gloucester, MA’s Fishermen’s Wives Memorial to life through recorded stories illuminating the wives’ strength and resilience over the centuries. Volunteering Virtually in Our Communities To promote civic engagement while simultaneously improving our people’s overall sense of engagement and purpose, Applied offered mostly virtual volunteering opportunities in 2021. From workshops where employees could learn about an issue, to virtual hands-on kit-building projects, to offering virtual career advice to youth, these opportunities were open to all Applied employees worldwide. By listening to community organizations about their real needs, we help assure that activities are truly meaningful and impactful for both the nonprofit and our people. INTRODUCTION PURPOSE Corporate Governance Ethics & Compliance Public Policy Data & IP Security Personal Data Privacy Community Impact PEOPLE PLANET PROGRESS Recognizing U.S. First Responders, Veterans, and Healthcare Workers Inspired by the 20th anniversary of 9/11, the Applied Materials Foundation joined with World Central Kitchen and 9/11 Day to deliver thank-you meals to first responders, healthcare workers, and veterans throughout the country.

Sustainability Report 2021 30 Invest in People We are building a deep-rooted Culture of Inclusion and fostering a diverse and skilled talent pipeline. INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS

We are a diverse team of problem solvers. We embrace challenges, break barriers and work together to make the world a better place. We value diversity of thought, experience, culture and expertise because they strengthen our business and power the innovations that define our enterprise. At Applied Materials, our inclusive culture starts with each of us, from the boardroom to the cleanroom. We work hard to be a place where employees across every geography and discipline feel supported personally and professionally and have the resources to empower continuous learning and career growth. At Applied, our employees define their career paths with support from their managers and the organization, and we help provide the tools to amplify their impact—both as individuals and as managers and leaders. We value our people not just as employees, but as human beings, and support them in creating their best lives and focusing on what matters most. We provide access to benefits that promote health, wellness, financial security and workplace flexibility, and are absolutely committed to workplace and employee safety. Before, during, and after the COVID crisis, we take care of our people. Sustainability Report 2021 31 Sustainability Report 2021 31 We cultivate a culture where every person knows they belong, feels empowered to contribute to their full potential and is inspired to grow their career at Applied Materials. Invest in People KEY HIGHLIGHTS > Introduced a virtual onboarding process to ease new emplo yees’ glidepath onto the Applied team > Engaged 2,800 global employees and contingent workers in our virtual Global Culture of Inclusion Summit > Enlisted 87% of the Applied Leadership Group in an inclusive leadership program that raises consciousness, strengthens cultural competency and promotes courageous action > Implemented an alternate workplace location process to give employees greater flexibility > Provided all employees with supplemental sick time hours to respond to COVID-related issues > Received a 2022 Training APEX Award from Training Magazine, ranking sixth out of 95 companies Sustainability Report 2021 31 INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS

Sustainability Report 2021 32 Sustainability Report 2021 32 Goals and Progress GOAL PROGRESS UN SDG Invest in People Increase women’s representation at Applied globally Increased representation from 17.8% to 18.1% (+0.3pp) Increase women’s representation at Applied in the U.S. to 21% by calendar year 2021 Increased representation to 21% in calendar year 2021 (20.8% in FY21), achieving our goal. Increase underrepresented minorities’ (URM) representation in our U.S. workforce Increased representation from 14.2% to 16.4% (+2.2pp) Maintain occupational health and safety total case incident rate (TCIR) of 0.42 or below Achieved a TCIR of 0.45 (industry TCIR was 0.70, based on U.S. Department of Labor Bureau of Labor Statistics 2018 Injury and Illness Rates) Our 2021 referral bonus increase contributed to a 4.4% increase in referral hires, rising from 17.4% (FY20) to 21.8% (FY21). “Engineers at Applied are encouraged to think the way others think cannot be done. So we dream big, think outside the box to make the impossible possible. We appreciate the difference of background, perspectives and experience. That diversity inspires engagement, creativity, and invention. People feel valued and respected and feel comfortable to contribute.” Cher, Senior Mechanical Engineer Manager Sustainability Report 2021 32 INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS

Sustainability Report 2021 33 Sustainability Report 2021 33 Diverse Talent Recruitment Our diverse talent recruiting seeks candidates from the technology industry and related fields and attracts talented new college graduates (NCGs) from universities with strong engineering and science programs—including U.S. schools with large Black and Hispanic student populations. Through STEM education initiatives with colleges, universities and nonprofit partners serving middle and high school students, we are also building a pipeline of future talent. Over the past two years, we’ve pursued a range of initiatives and technologies to help us achieve our diversity goals: > Introducing a Diverse Talent Sourcing Platform that enables searches for diverse candidates > Rolling out a global Talent Selection Playbook that helps managers define their talent needs, then assess and select the most appropriate candidates > Doubling our referral bonus program to reward employees for recommending successful candidates for customer engineering and other technical roles > Expanding talent searches beyond our physical operating regions to broaden our potential talent pool > Recruiting military talent as they exit the U.S. services These initiatives and others have contributed to an increase in the representation of global women, U.S. women and U.S. URM employees at Applied. As leaders in the technology industry, our total commitment to inclusion and diversity informs and enables all our practices for attracting, recruiting, hiring and onboarding a top-performing workforce. In 2021, continuing pandemic challenges and a hyper-competitive labor market complicated the task of meeting our growing skill needs, especially in semiconductor technologies. Recruiting and Hiring Supporting the Everywhere Workplace In 2021, we implemented a new alternative workplace location process, enabling flexibility for our employees when personal circumstances arise. By supporting remote, flexible models, we are better able to recruit and retain the best talent for our teams. INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS

Sustainability Report 2021 34 For the fourth year, Applied Materials was given the Excellence Employer award by China’s #1 jobs board, 51Job, recognizing our achievements in diversity and inclusion. “Applied Materials constantly seeks ways to improve as a company. Whether it’s addressing environmental and sustainability challenges, shrinking gender equity discrepancies, or promoting a more inclusive workplace, these efforts make me love working at a global company that listens to employees and leverages the various talents and diverse backgrounds that make up Applied’s culture.” Hadley Sales Account Manager Recruiting and Hiring in Challenging Times Throughout 2021, we adapted and expanded our recruiting, hiring and onboarding practices for a challenging labor and work environment. Our efforts included: > Applied New Hire Experience. As part of our MY HR portal, we introduced a virtual onboarding process that orients new hires to our values, mission, business organization, locations and other essentials, all via modules and notifications that promote better engagement and information retention. The system coordinates with the employee’s manager and a new-hire buddy, simplifying and standardizing the onboarding process. > New College Graduate Rotation Programs. To drive in-depth, cross- functional training, provide access to a global knowledge database and assure optimal placement of new hires, internal organizations including Supply Chain, Finance (Austin and Silicon Valley), and Implant (Gloucester) offered rotation programs that included mentoring, networking, skills development and hands-on experience across various areas of their operation. > Virtual Internships. In North America and globally, our virtual internship programs continued giving students exposure to our diverse and inclusive workplace and introducing them to career paths and roles in both engineering and corporate. In the U.S., we hired a total of 143 interns, 53% of whom were female. > China New Star Program. Spanning 12 Applied locations in China, this NCG program saw 13% female new hires in 2021. INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS

Sustainability Report 2021 35 Sustainability Report 2021 35 Eliminate systemic barriers to inclusion Identify and break down systemic barriers to inclusion Engage and empower Inclusion Change Teams to break down barriers Leverage data to develop action strategies to inclusion In 2021, we made significant progress in strengthening our COI strategy, targets, training commitments and data disclosure, working toward our goal of moving to a higher level of DEI maturity as structured in the Global Diversity, Equity & Inclusion Benchmarks. At Applied Materials, we believe the future of work is one where diversity, equity and inclusion (DEI) are intrinsic to the organization, helping foster a growth- oriented mindset, build stronger and more resilient teams, and enable Applied Materials to innovate and succeed. Our Culture of Inclusion 35 “Applied Materials is operationalizing a Culture of Inclusion across every aspect of our company—every business group, every function, every process, every region. This is far beyond an HR initiative; it is fully integrated cultural transformation that will inform and drive our business strategy. By engaging leaders as champions of change, eliminating systemic barriers, and inspiring employees, we are creating a Culture of Inclusion where everyone—and hence, Applied—can reach our full potential.” Michelle Cooper Vice President of Culture of Inclusion Engage leaders as champions of change Make inclusion personal for leaders Define metrics and leader accountability for change Operationalize inclusion in all we do Ensure talent practices are inclusive Accelerate strategies for finding, selecting, placing, developing, and retaining talent Measure qualitative and quantitative progress COI Strategy: Foundation and Roadmap INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS

Sustainability Report 2021 36 Sustainability Report 2021 Applied Inclusion: It Starts with Me While leaders play a central role in driving organizational change, making that change sustainable takes everyone, at every level of our global enterprise. It means embracing change as a philosophy, not just tweaking the tactics and strategies of the past. At its most basic level, it’s about breaking the cycle of looks-like-me hiring, going beyond expectations of background, education and experience to see new possibilities. However, DEI has to be more holistic than just talent, embracing an expansive and empathetic mindset that not only sees but seeks the value in difference and works toward that ideal in everything we do, including: > Identifying more diverse suppliers > Respecting and celebrating all individuals > Creating safe spaces where all voices can be heard > Reinventing our culture to value a healthier work/life balance > Embedding that culture of respect, empathy, and collaboration across our strategy and business processes 2021 Global Culture of Inclusion Summit While the definition of diversity may vary from country to country, the concepts of equity and inclusion are universal and set us up for a future of greater collaboration, innovation, and financial performance. That was the message of our October 2021 virtual Global Culture of Inclusion Summit, which netted the participation of more than 2,800 global employees and contingent workers. Around the world, from the U.S. and Europe to China, India, Singapore, Taiwan, Korea, and Japan, Applied’s teams hosted speakers and local training on topics such as developing an inclusive mindset, learning and operationalizing the traits of Inclusive Leadership, overcoming multi-generational issues, reducing identity-covering in the workplace, and becoming an LGBTQIA+ ally. Featured speakers at the summit included: > Pulitzer-winning journalist and author Isabel Wilkerson (The Warmth of Other Suns, Caste: The Origin of Our Discontents) > Veteran astronaut Dr. Ellen Ochoa, the first Hispanic and second female director of the Johnson Space Center > Retired Army General Stanley McChrystal, former commander of the U.S. Joint Special Operations Command and U.S. forces in Afghanistan > Lori N. McKenzie, lead strategist for Diversity, Equity & Inclusion at Stanford Graduate School of Business and cofounder of the Stanford VMware Women’s Leadership Innovation Lab 36 INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS

Sustainability Report 2021 37 “Through WE TDP 2 , I gained the confidence to speak up, the courage to say yes to possibilities, and the spirit to lift up others and myself.” Sharon Product Manager Growing a Diverse Workforce In FY2021, as the tight global talent market made our strategic efforts to retain and recruit diverse talent even more imperative, we posted several notable gains: > The percentage of underrepresented minorities in our U.S. workforce increased by 2.2 percentage points (pp) year over year, rising from 14.2% to 16.4%. > Globally, women’s representation in our workforce increased by 0.3pp, rising from 17.8% to 18.1%. > Women’s representation in our U.S. workforce increased by 0.6pp, from 20.2% to 20.8% 1 . > Women’s representation among global leadership increased 1.0pp, from 11.2% to 12.2%. Additionally, we continue to make progress in increasing women’s representation at the customer support and technician level. See Diverse Talent Recruitment earlier in this chapter for additional information. Sustainability Report 2021 37 INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS 1 We reached the goal of 21% by the end of CY2021 2 Women in Engineering Talent Development Program (WE TPD)

Sustainability Report 2021 38 FY2021 U.S. Workforce Gender, Ethnicity, and Race Representation by Employee Level Executives Vice Presidents and Directors Managers People Managers Professionals Business, Engineering and Sales Career Bands Women Asian Black Hispanic/Latinx Other URMs* White 12.7% 46.0% 1.0% 2.6% 1.10% 48.9% 40.5% 11.3% 1.0% 2.0% 0.80% 55.6% + 1.4% + 5.5% 0% – 6.7% + 0.6% + 0.3% 49.6% 19.0% 34.9% 4.7% 8.2% 2.4% 12.4% 61.7% 29.0% 3.1% 5.3% 0.7% – 12.1% + 6.6% + 5.9% + 1.7% + 1.6% + 2.9% 2.4% 40.9% 26.8% 45.6% 2.9% 7.4% 48.9% 1.1% 24.1% 40.6% 2.9% 6.4% + 1.3% – 8.0% + 2.7% + 1.0% + 5.0% 0% 2021 2016 INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS * Underrepresented minorities

Sustainability Report 2021 39 2016 2018 2019 2017 2021 18% 10.8% 11.7% 12.2% 12.4% 12.9% 13.2% 12.7% 12.2% 11.6% 11.4% 15.5% 14.6% 14.5% 15.4% 16.5% 15.7% 14.9% 14.8% 15.6% 16.7% 18.8% 19.3% 19.5% 20.2% NA EMEA APAC U.S. Women Global Women 2020 18.3% 15.6% 20.8% 2016 2018 2019 2017 2021 2020 13.5% 13.9% 2016 2018 2019 2017 2021 18% 10.8% 11.7% 12.2% 12.4% 12.9% 13.2% 12.7% 12.2% 11.6% 11.4% 15.5% 14.6% 14.5% 15.4% 16.5% 15.7% 14.9% 14.8% 15.6% 16.7% 18.8% 19.3% 19.5% 20.2% NA EMEA APAC U.S. Women Global Women 2020 18.3% 15.6% 20.8% 2016 2018 2019 2017 2021 2020 13.5% 13.9% Female Representation by Region 2016–2021 Improved Gender Diversity in Engineering Women in Engineering Talent Development Program Our Women in Engineering Talent Development Program (WE TDP) is focused on supporting the career growth of female technical talent at Applied. This two-year development program offers resources to support a select group of high-potential U.S. women in engineering-related roles through networking opportunities, conference participation, professional skill development workshops, career development roundtables, and mentoring programs. Women are nominated by their managers annually. Membership in WE TDP tends to correlate with increased retention, and many WE TDP alumni and year-two members have received promotions. Sustainability Report 2021 39 INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS

Sustainability Report 2021 40 Engaging Leaders as Champions of Change As our Culture of Inclusion effort intensifies, Applied Materials’ leaders are investing in their own awareness as an essential component of driving change. In 2021, we launched our virtual, half-day Inclusive Leader Summits, experiential learning opportunities designed to reinforce and extend last year’s learnings about leading courageously on race and racial equity. Targeted at the 400 members of our Applied Leadership Group (ALG), the workshops achieved an 87% attendance rate, including leadership from our Europe and Israel operations. Fifteen of our U.S. leaders also participated in a pilot Coaching for Inclusion program through the Berkeley Executive Coaching Institute. Building on previous diversity training that focused on gaining a deeper understanding of inclusion challenges and making inclusion personal, the Berkeley program is designed to give leaders the skills and tools to learn across difference to drive meaningful, sustainable change. Its focus includes: > Building core capabilities and helping leaders develop an authentic leadership presence around DEI > Building empathy and an understanding of how DEI issues affect oneself and others > Becoming more conscious of how personal behaviors can unintentionally reinforce unproductive dynamics The program is delivered via an initial two- day session, coaching, independent study, and a follow-up workshop. For 2022, we intend to take this program global, training three cohorts of 21 leaders apiece, including in our Asia-Pacific operation. Our Inclusive Leader Action Guide, introduced in the first half of 2021, continued to serve as a resource for our executive staff and people managers, providing pragmatic strategies and best practices for becoming more inclusive leaders, partners, and change catalysts. These efforts build on changes introduced in prior years to help our leaders take Applied Materials in the direction we need to go— such as introducing diversity dashboards that allow U.S. leaders to track progress against diversity goals for each organization, and tying executive compensation directly to the achievement of our diversity objectives via our Corporate Scorecard. Our COI progress is shared on a quarterly basis with our Board of Directors. Over the past several years our Board itself has grown more diverse, and now consists of 40% women and 30% people of color. Workforce Diversity Recognition Applied Materials is consistently recognized for our efforts around workforce diversity and military veteran recruitment. Military Friendly Employer 100%-plus overall rating, exceeds every standard U.S. Veterans Magazine Top Veteran-Friendly Company Human Rights Campaign Foundation Corporate Equality Index, 100% overall rating Best Places to Work for LGBTQ+ Equality Woman Engineer Magazine Top 50 Employers INTRODUCTION PURPOSE PEOPLE Recruiting and Hiring Our Culture of Inclusion Learning and Development Employee Safety and Support During COVID-19 Occupational Health and Safety Human Rights PLANET PROGRESS