HP Sustainable Impact Report

HP Sustainable Impact Report 2021

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Table of contents See the standalone 2021 HP Sustainable Impact Report Executive Summary. 3 Letter from our President and CEO 28 Supply chain responsibility 54 Greenhouse gas emissions 91 Appendix 4 About HP 29 Approach 56 Water 92 About this report 31 Human rights 57 Waste 94 Policies and standards 5 Sustainable Impact 58 Community giving and volunteerism 31 Health and safety 58 HP Foundation programs 95 Independent accountants’ review report 6 Sustainable Impact strategy 32 Responsible minerals sourcing 98 ESG material topics 10 Recognition 60 Disaster recovery and resilience 34 Supplier diversity 60 Employee volunteerism 100 Sustainability Bond progress statement 11 Governance 35 Environmental impact 101 United Nations Global Compact index 11 Stakeholder engagement 61 Data 36 Greenhouse gas emissions 102 United Nations Sustainable Development 12 ESG materiality 38 Water 66 Products and solutions Goals index 38 Waste 67 Circular and net zero carbon economy 103 Sustainability Accounting Standards 14 Footprint 39 Performance monitoring and evaluation Board index 15 Carbon and climate impact 70 Product circularity 104 Task Force on Climate-Related Financial 43 Data 74 Energy efficiency 16 Water Disclosures index 75 Sustainable materials 105 WEF IBC Stakeholder Capitalism 17 Data 45 Operations 81 Forest positive Metrics index 20 Integrity and human rights 46 Our employees 82 Product responsibility 106 GRI index 46 Diversity, equity, and inclusion 82 Product safety 112 Endnotes 21 Ethics and anti-corruption 49 Employee engagement 83 Product security and privacy 21 Ethics 50 Employee development 84 Social impact 22 Anti-corruption 51 Compensation and benefits 85 Education 23 Human rights 51 Health and safety 87 Healthcare 25 Privacy 52 Wellbeing 88 Accessibility 26 Cybersecurity 53 Our facilities 89 Data 27 Public policy 53 Environmental, health, and safety management Cover image: Empowering girls HP partner, Girl Rising, uses the power of storytelling to highlight the connection between girls’ education and climate change. 2 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Letter from our President and CEO We are confronting a set of global challenges that are personal systems and print product portfolio to 13%, as Digital Equity testing the very foundation on which our society is built. we aim for 30% by 2025. We are also committed to helping break down the From an ongoing pandemic to our accelerating climate We also are disrupting the US$10 billion fiber-based barriers that exclude many from participating in the crisis to persistent inequality, these challenges impact sustainable packaging market, with our 3D printing– digital economy. Nearly 3 billion people around the all of us. And the way we respond will help shape our enabled HP Molded Fiber Advanced Tooling Solution and world remain offline due to lack of access, affordability, future in profound and lasting ways. acquisition of Choose Packaging, the inventor of the only or usability. The COVID-19 pandemic exposed the depth Companies like ours have a critical role to play in known commercially available zero-plastic paper bottles. of this issue and even exacerbated it, as many schools helping solve these challenges. That’s why, in 2021, and businesses began operating remotely. we announced one of the most comprehensive We are partnering with leading conservation and That’s why, in 2021, we pledged to accelerate digital environmental and social impact agendas in our environmental organizations, including the World equity for 150 million people by the end of the decade— industry—with aggressive goals focused on climate Wildlife Fund, Conservation International, the Arbor Day a goal we aim to meet with the collaboration and action, human rights, and digital equity. And we have Foundation, and the Jane Goodall Institute, to invest support of key priority partners, like Girl Rising, NABU, been taking decisive action to meet them. in forest restoration and responsible management to MIT Solve, and Aspen Digital, through the Digital Equity counteract deforestation for non-HP paper used in HP Accelerator program launched in February 2022. In our 21st annual Sustainable Impact report, we share printers and print services. Since 2020, all HP brand the progress we are making. There are areas where we paper and paper-based packaging for home and office Building a stronger HP are leading but also opportunities for us to do more. printers and supplies, PCs, and displays have been From our earliest days as a company, HP has been Our teams are operating with the deep sense of derived from recycled or certified sources. a place where innovation drives extraordinary urgency needed to make continuous improvements, Finally, we are broadening our impact by engaging our contributions to humanity. Time and again, our people while forging partnerships to maximize our impact. hundreds of production suppliers and thousands of have had the vision to see entirely new possibilities for While no single company, sector, or even country can non-production suppliers in sustainability programs. the role we can play in the world—and the ingenuity to solve the enormous global challenges before us, we In early 2022, we expanded our Amplify Impact channel create technology that inspires ambitious progress. know we can create a better future by working together. partner program to empower more than 10,000 Climate Action partners in over 40 countries to advance their own That vision and ingenuity is reflected in the progress we sustainable impact journeys. are making against our Sustainable Impact goals today. Of all the challenges facing the world, none is greater And the impact on the world—and our business—is clear. than our climate crisis. And so, we set an ambitious Human Rights In fact, our Sustainable Impact initiatives helped the climate goal: By 2040, HP’s entire value chain—Scope 1, Even as we work to deepen our impact, we are focused company win more than US$3.5 billion in new sales in 2, and 3—will reach net-zero greenhouse gas emissions, on expanding the diversity of our workforce. Building a fiscal year 2021—a three-fold increase over the prior year. with a 50% reduction in absolute emissions by the end diverse and inclusive workforce is not only the right thing Simply put, when we innovate with purpose, we create of this decade. We’ve already achieved a 9% absolute to do—it also makes good business sense. Diverse teams the conditions for both business and society to thrive. reduction since 2019—but we know we must move faster. will always out-innovate and out-perform the market. Saludos, So, we’re rethinking our materials, as well as how to keep I am inspired by the progress we are making toward them in circular use, and how to reduce our footprint. We aim to double the number of Black and African becoming the world’s most sustainable and just American HP executives by 2025 and reach 50/50 technology company. And I hope our success spurs We’ve made significant progress in reducing gender equality in leadership by 2030. And while HP other businesses to join us in creating the future we plastic waste and using more recycled plastic. We is among the top technology companies for women in want to see—for our companies, our families, and have reduced single-use plastic packaging by 44% leadership positions—and nearly 45% of our U.S. hires our communities. Enrique Lores compared to 2018. And we have increased the use of in 2021 were racial/ethnic minorities—we are exploring President and CEO postconsumer recycled content plastic across our ways to improve inclusive representation at all levels. 3 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

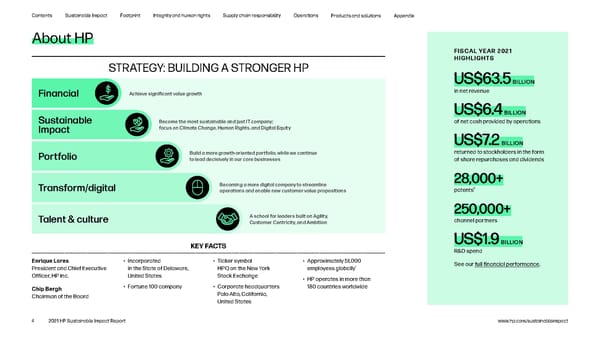

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix About HP FISCAL YEAR 2021 HIGHLIGHTS STRATEGY: BUILDING A STRONGER HP US$63.5 BILLION Financial Achieve significant value growth in net revenue US$6.4 BILLION Sustainable Become the most sustainable and just IT company; of net cash provided by operations Impact focus on Climate Change, Human Rights, and Digital Equity US$7.2 BILLION Portfolio Build a more growth-oriented portfolio, while we continue returned to stockholders in the form to lead decisively in our core businesses of share repurchases and dividends Becoming a more digital company to streamline 28,000+ Transform/digital operations and enable new customer value propositions patents2 250,000+ Talent & culture A school for leaders built on Agility, channel partners Customer Centricity, and Ambition KEY FACTS US$1.9 BILLION R&D spend Enrique Lores • Incorporated • Ticker symbol • Approximately 51,000 See our full financial performance. 1 President and Chief Executive in the State of Delaware, HPQ on the New York employees globally Officer, HP Inc. United States Stock Exchange • HP operates in more than Chip Bergh • Fortune 100 company • Corporate headquarters 180 countries worldwide Chairman of the Board Palo Alto, California, United States 4 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Sustainable Impact 6 Sustainable Impact strategy 11 Stakeholder engagement 10 Recognition 12 ESG materiality 11 Governance 5 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

This is a modal window.

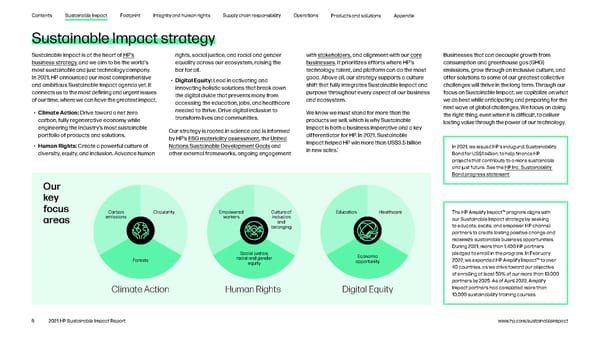

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Sustainable Impact strategy Sustainable Impact is at the heart of HP’s rights, social justice, and racial and gender with stakeholders, and alignment with our core Businesses that can decouple growth from business strategy, and we aim to be the world’s equality across our ecosystem, raising the businesses. It prioritizes efforts where HP’s consumption and greenhouse gas (GHG) most sustainable and just technology company. bar for all. technology, talent, and platform can do the most emissions, grow through an inclusive culture, and In 2021, HP announced our most comprehensive • Digital Equity: Lead in activating and good. Above all, our strategy supports a culture offer solutions to some of our greatest collective and ambitious Sustainable Impact agenda yet. It innovating holistic solutions that break down shift that fully integrates Sustainable Impact and challenges will thrive in the long term. Through our connects us to the most defining and urgent issues the digital divide that prevents many from purpose throughout every aspect of our business focus on Sustainable Impact, we capitalize on what of our time, where we can have the greatest impact. accessing the education, jobs, and healthcare and ecosystem. we do best while anticipating and preparing for the needed to thrive. Drive digital inclusion to next wave of global challenges. We focus on doing • Climate Action: Drive toward a net zero We know we must stand for more than the the right thing, even when it is difficult, to deliver carbon, fully regenerative economy while transform lives and communities. products we sell, which is why Sustainable lasting value through the power of our technology. engineering the industry’s most sustainable Our strategy is rooted in science and is informed Impact is both a business imperative and a key portfolio of products and solutions. by HP’s ESG materiality assessment, the United differentiator for HP. In 2021, Sustainable • Human Rights: Create a powerful culture of Nations Sustainable Development Goals and Impact helped HP win more than US$3.5 billion In 2021, we issued HP’s inaugural Sustainability 1 diversity, equity, and inclusion. Advance human other external frameworks, ongoing engagement in new sales. Bond for US$1 billion, to help finance HP projects that contribute to a more sustainable and just future. See the HP Inc. Sustainability Bond progress statement. Our key focus Carbon Circularity Empowered Culture of Education Healthcare The HP Amplify Impact™ program aligns with areas emissions workers inclusion our Sustainable Impact strategy by seeking and to educate, excite, and empower HP channel belonging partners to create lasting positive change and maximize sustainable business opportunities. During 2021, more than 1,400 HP partners Social justice, Economic pledged to enroll in the program. In February Forests racial and gender opportunity 2022, we expanded HP Amplify Impact™ to over equity 40 countries, as we drive toward our objective of enrolling at least 50% of our more than 10,000 partners by 2025. As of April 2022, Amplify Climate Action Human Rights Digital Equity Impact partners had completed more than 10,000 sustainability training courses. 6 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

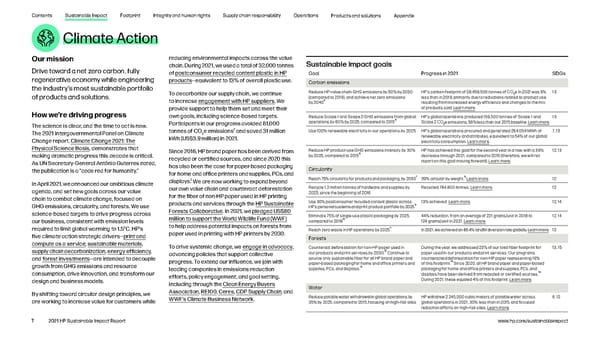

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Climate Action Our mission reducing environmental impacts across the value Sustainable Impact goals Drive toward a net zero carbon, fully chain. During 2021, we used a total of 32,000 tonnes of postconsumer recycled content plastic in HP Goal Progress in 2021 SDGs regenerative economy while engineering products—equivalent to 13% of overall plastic use. Carbon emissions the industry’s most sustainable portfolio Reduce HP value chain GHG emissions by 50% by 2030 HP’s carbon footprint of 28,459,500 tonnes of CO e in 2021 was 9% 13 To decarbonize our supply chain, we continue 2 of products and solutions. (compared to 2019), and achieve net zero emissions less than in 2019, primarily due to reductions related to product use to increase engagement with HP suppliers. We by 20404 resulting from increased energy efficiency and changes to the mix provide support to help them set and meet their of products sold. Learn more. How we’re driving progress own goals, including science-based targets. Reduce Scope 1 and Scope 2 GHG emissions from global HP’s global operations produced 159,500 tonnes of Scope 1 and 13 operations by 60% by 2025, compared to 20155 Scope 2 CO e emissions, 59% less than our 2015 baseline. Learn more. The science is clear, and the time to act is now. Participants in our programs avoided 81,000 2 tonnes of CO 2 Use 100% renewable electricity in our operations by 2025 HP’s global operations procured and generated 264,054 MWh of 7, 13 The 2021 Intergovernmental Panel on Climate 2e emissions and saved 31 million kWh (US$3.9 million) in 2021. renewable electricity and attributes, equivalent to 54% of our global Change report, Climate Change 2021: The electricity consumption. Learn more. Physical Science Basis, demonstrates that Since 2016, HP brand paper has been derived from Reduce HP product-use GHG emissions intensity by 30% HP has achieved this goal for the second year in a row, with a 39% 12, 13 making dramatic progress this decade is critical. by 2025, compared to 20156 decrease through 2021, compared to 2015 (therefore, we will not As UN Secretary-General António Guterres noted, recycled or certified sources, and since 2020 this report on this goal moving forward). Learn more. the publication is a ”code red for humanity.” has also been the case for paper-based packaging Circularity for home and office printers and supplies, PCs, and 7 8 3 Reach 75% circularity for products and packaging, by 2030 39% circular by weight. Learn more. 12 In April 2021, we announced our ambitious climate displays. We are now working to expand beyond agenda, and set new goals across our value our own value chain and counteract deforestation Recycle 1.2 million tonnes of hardware and supplies by Recycled 764,800 tonnes. Learn more. 12 for the fiber of non-HP paper used in HP printing 2025, since the beginning of 2016 chain to combat climate change, focused on Use 30% postconsumer recycled content plastic across 13% achieved. Learn more. 12, 14 GHG emissions, circularity, and forests. We use products and services through the HP Sustainable HP’s personal systems and print product portfolio by 20259 science-based targets to drive progress across Forests Collaborative. In 2021, we pledged US$80 Eliminate 75% of single-use plastic packaging by 2025, 44% reduction, from an average of 221 grams/unit in 2018 to 12, 14 million to support the World Wildlife Fund (WWF) compared to 201810 124 grams/unit in 2021. Learn more. our business, consistent with emission levels required to limit global warming to 1.5°C. HP’s to help address potential impacts on forests from Reach zero waste in HP operations by 202511 In 2021, we achieved an 86.4% landfill diversion rate globally. Learn more. 12 five climate action strategic drivers—print and paper used in printing with HP printers by 2030. Forests compute as a service, sustainable materials, To drive systemic change, we engage in advocacy, Counteract deforestation for non-HP paper used in During the year, we addressed 23% of our total fiber footprint for 13, 15 supply chain decarbonization, energy efficiency, 12 advancing policies that support collective our products and print services by 2030. Continue to paper used in our products and print services. Our programs and forest investments—are intended to decouple source only sustainable fiber for all HP brand paper and counteracted deforestation for non-HP paper representing 19% progress. To extend our influence, we join with 14 paper-based packaging for home and office printers and of this footprint. Since 2020, all HP brand paper and paper-based growth from GHG emissions and resource 13 leading companies in emissions-reduction supplies, PCs, and displays. packaging for home and office printers and supplies, PCs, and consumption, drive innovation, and transform our 15 efforts, policy engagement, and goal setting, displays have been derived from recycled or certified sources. design and business models. During 2021, these equaled 4% of this footprint. Learn more. including through the Clean Energy Buyers Water By shifting toward circular design principles, we Association, RE100, Ceres, CDP Supply Chain, and WWF’s Climate Business Network. Reduce potable water withdrawal in global operations by HP withdrew 2,245,000 cubic meters of potable water across 6, 12 are working to increase value for customers while 35% by 2025, compared to 2015, focusing on high-risk sites global operations in 2021, 30% less than in 2015, and focused reduction efforts on high-risk sites. Learn more. 7 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

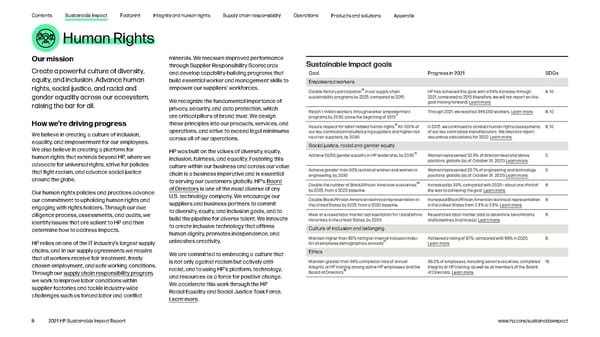

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Human Rights Our mission minerals. We measure improved performance Sustainable Impact goals Create a powerful culture of diversity, through Supplier Responsibility Scorecards and develop capability-building programs that Goal Progress in 2021 SDGs equity, and inclusion. Advance human build essential worker and management skills to Empowered workers rights, social justice, and racial and empower our suppliers’ workforces. 16 8, 10 Double factory participation in our supply chain HP has achieved this goal, with a 114% increase through gender equality across our ecosystem, We recognize the fundamental importance of sustainability programs by 2025, compared to 2015 2021, compared to 2015 (therefore, we will not report on this raising the bar for all. goal moving forward). Learn more. privacy, security, and data protection, which Reach 1 million workers through worker empowerment Through 2021, we reached 349,000 workers. Learn more. 8, 10 are critical pillars of brand trust. We design programs by 2030, since the beginning of 201517 How we’re driving progress these principles into our products, services, and 18 8, 10 operations, and strive to exceed legal minimums Assure respect for labor-related human rights for 100% of In 2021, we continued to conduct human rights assessments We believe in creating a culture of inclusion, our key contracted manufacturing suppliers and higher-risk of our key contracted manufacturers. We intend to report across all of our operations. next-tier suppliers, by 2030 assurance calculations for 2022. Learn more. equality, and empowerment for our employees. Social justice, racial and gender equity We also believe in creating a platform for HP was built on the values of diversity, equity, human rights that extends beyond HP, where we Achieve 50/50 gender equality in HP leadership, by 203019 Women represented 32.5% of director-level and above 5 inclusion, fairness, and equality. Fostering this positions globally (as of October 31, 2021). Learn more. advocate for universal rights, strive for policies culture within our business and across our value that fight racism, and advance social justice chain is a business imperative and is essential Achieve greater than 30% technical women and women in Women represented 22.7% of engineering and technology 5 around the globe. engineering, by 2030 positions globally (as of October 31, 2021). Learn more. to serving our customers globally. HP’s Board 20 of Directors is one of the most diverse of any Double the number of Black/African American executives Increased by 33%, compared with 2020—about one-third of 8 Our human rights policies and practices advance by 2025, from a 2020 baseline the way to achieving the goal. Learn more. our commitment to upholding human rights and U.S. technology company. We encourage our Double Black/African American technical representation in Increased Black/African American technical representation 8 engaging with rights holders. Through our due suppliers and business partners to commit the United States by 2025, from a 2020 baseline in the United States from 2.3% to 2.6%. Learn more. diligence process, assessments, and audits, we to diversity, equity, and inclusion goals, and to Meet or exceed labor market representation for racial/ethnic Researched labor market data to determine benchmarks 8 identify issues that are salient to HP and then build the pipeline for diverse talent. We innovate minorities in the United States, by 2030 and baselines (in process). Learn more. determine how to address impacts. to create inclusive technology that affirms Culture of inclusion and belonging human dignity, promotes independence, and Maintain higher than 90% rating on internal inclusion index Achieved a rating of 87%, compared with 89% in 2020. 8 unleashes creativity. 21 HP relies on one of the IT industry’s largest supply for all employee demographics annually Learn more. chains, and in our supply agreements we require We are committed to embracing a culture that Ethics that all workers receive fair treatment, freely is not only against racism but actively anti- Maintain greater than 99% completion rate of annual 99.2% of employees, including senior executives, completed 16 chosen employment, and safe working conditions. Integrity at HP training among active HP employees and the Integrity at HP training, as well as all members of the Board racist, and to using HP’s platform, technology, Board of Directors22 of Directors. Learn more. Through our supply chain responsibility program, and resources as a force for positive change. we work to improve labor conditions within We accelerate this work through the HP supplier factories and tackle industry-wide Racial Equality and Social Justice Task Force. challenges such as forced labor and conflict Learn more. 8 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Digital Equity Our mission we aspire to help pave the way toward a more Sustainable Impact goals Lead in activating and innovating holistic equitable world where women and girls, people with disabilities and aging populations, historically Goal Progress in 2021 SDGs solutions that break down the digital excluded and marginalized communities, and Digital Equity divide that prevents many from accessing educators and healthcare practitioners have 23 access to the technology and resources they Accelerate digital equity for 150 million people by 2030, Accelerated digital equity for 4.3 million people. Learn more. 4, 5, 8 the education, jobs, and healthcare since the beginning of 2021 needed to thrive. Drive digital inclusion need to ensure their voices are heard. Enroll 1.5 million HP LIFE users between 2016 and 2030 Enrolled 533,000 since 2016. Learn more. 4, 5, 8 to transform lives and communities. We plan to achieve this through impactful Learning outcomes programs, strategic investments, and partnerships. Enable better learning outcomes24 for 100 million people 74.3 million students and adult learners have benefited 4, 5, 8 How we’re driving progress For example, we are supporting nonprofit NABU’s by 2025, since the beginning of 2015 from HP’s education programs and solutions that advance work to improve childhood literacy in marginalized quality learning and digital literacy, and enable better Nearly half of the world’s population remains learning outcomes, since the beginning of 2015 (including communities through books in children’s native 24 million in 2021). Learn more. unconnected to the internet and locked out of languages. We continue enhancing the HP Community opportunity, including vital access to education, Foundation’s free HP LIFE program to make healthcare, and economic opportunity. Contribute US$100 million in HP Foundation and employee Reached US$73.4 million in HP Foundation and employee 11, 17 entrepreneurial skill building more accessible to all. community giving25 community giving. Learn more. by 2025 (cumulative since the beginning In 2021, HP set a goal to accelerate digital equity of 2016) Along with our strategic partners, our employees Contribute 1.5 million employee volunteering hours by 2025 Reached 692,000 employee volunteering hours. 11, 17 for 150 million people by 2030. Through the Digital contribute their time, resources, and skills to (cumulative since the beginning of 2016) Learn more. Equity Accelerator (launched in early 2022), provide important support to local communities. HP’S RESPONSE TO COVID-19 The COVID-19 pandemic has challenged businesses large and small, local experts and public health leaders, and regularly review and update them donating PCs, printers, and displays. In support of our goal to accelerate and national governments, families, and individuals in ways few of us could to reflect the best, most current information available. digital equity, we provided technology and other support to underserved have imagined. students and families through Parents Supporting Parents. Learn more As conditions allow, we are moving into our next phase of return to office about HP’s community giving and volunteerism. The wellbeing of our employees and their families has remained a top planning and are beginning to fully reopen HP offices on a site-by-site priority. With many of our employees working from home, we have basis in line with local health and safety regulations. US$389,000 167,000+ initiatives that promote physical and mental health and work/life balance, including through HP Spirit and Well Beyond. At our sites, we’ve put in In 2021, HP and the HP Foundation continued to support impacted in HP Foundation grants related COVID-19 vaccinations given place global policies and protocols based on guidance from healthcare communities around the world, contributing financial resources and to COVID-19 through HP’s CSR India team 9 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Recognition HP is recognized as one of the world’s most sustainable companies. Named for the seventh One of the 2022 World’s Only technology company Honored for commitment year in a row to this list of Most Ethical Companies— globally to receive a triple “A” to and momentum toward the 100 Most Sustainable named to this list for the rating across CDP’s Climate, creating sustainable markets Corporations in the World third year in a row Water, and Forests lists and Supplier Engagement Leaderboard (for the 3rd year in a row) Named #1 on Newsweek’s Listed on the Dow Jones Placed second among 100% score on the list for the third year in a row Sustainability World Index technology companies and Disability Equality Index for the 10th time in a row fourth overall for the sixth year in a row Rated among the top Ranked seventh out of Recognized for efforts Named a Top 50 Employer by companies for corporate 150 ICT companies on to advance diversity and Woman Engineer Magazine social responsibility for digital inclusion in 2021 inclusion for the sixth year the 12th time in a row in a row Ranked second on the 2020 Recognized for ongoing Received SmartWay Awarded Outstanding benchmark of ICT companies commitment to product Excellence Award for the Leadership in Sustainable committed to addressing energy efficiency for the 10th time overall (eighth Finance in 2021 human rights issues within fifth year in a row (third for year in a row) their supply chains Sustained Excellence) Ranked among the top three Placed in the top 10 for Received a 100% score on Named to JUST Capital’s list ICT companies on the clean energy for the fourth the Corporate Equality Index for the fourth year in a row 2020 Corporate Human year in a row for LGBTQ+ Equality for the Rights Benchmark 19th year Received award for efforts to address the challenge of ocean-bound plastics 10 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Governance Stakeholder engagement We integrate Sustainable Impact at all levels of of our board have experience in environmental We gain valuable insight through regular Examples of stakeholder engagement in 2021: the company. and social responsibility-related issues and engagement with a range of stakeholders, topics, which we believe strengthens the board’s including employees, investors, suppliers, • Decarbonization: We engage in initiatives Our executive leadership team, led by our CEO, oversight of HP’s policies and programs relating customers, peer companies, public policymakers, focused on increasing support for clean energy retains overall responsibility for Sustainable to these issues and reinforces HP’s commitment industry bodies, nongovernmental organizations and combating climate change, including Impact as part of our business strategy. All to sustainability and social responsibility. (NGOs), sector experts, and others. These RE100, CDP Supply Chain, WWF’s Climate members of the executive leadership team interactions build our collective intelligence, help Business Network, Business Ambition for oversee Sustainable Impact targets relevant to The performance and compensation of our Chief us prioritize critical issues, and provide insights 1.5°C, and Ceres. See Footprint, Supply chain their organizations, and are evaluated annually Impact Officer, our Chief Sustainability Officer, into emerging opportunities and risks. responsibility: Environmental impact, Our against objectives related to Sustainable Impact, and our Chief Diversity Officer are related to facilities, and Circular and net zero carbon including climate change and diversity, equity, and the management of HP Sustainable Impact and Our environmental, social, and governance economy: Energy efficiency. inclusion. Performance against these and other the achievement of related targets and metrics, (ESG) materiality assessment process is deeply • Circular economy: We are working with business objectives is tied to total compensation. both public and internal. Several other HP VPs, informed by stakeholder engagement. In 2021, partner organizations and suppliers to gain the directors, and managers have a component of interviews with a wide range of internal and most value from materials and to keep them The HP Board of Directors’ Nominating, total compensation (salary and bonus) based on external stakeholders and the results of an Governance and Social Responsibility (NGSR) responsibility for, and effective implementation external survey contributed to the analysis. in use, contributing to a circular economy. For Committee oversees the company’s policies and of, corporate initiatives to address climate action, Learn more. example, with the Ellen MacArthur Foundation programs relating to global citizenship and the human rights, and digital equity. Beginning in 2021, Circular Economy 100, we are driving progress impact of HP’s operations; provides guidance every HP employee is encouraged and supported Individual functions across the company drive toward a more circular materials- and energy- and recommendations to the board on legal, to set a Sustainable Impact goal as part of our decentralized approach, engaging in ways efficient future. We engage through the HP regulatory, and compliance matters relating to their individual annual goal-setting process. that are most relevant to their objectives Sustainable Forests Collaborative to protect, political, environmental, global citizenship, and Learn more. and operations. These include partnerships, restore, and improve responsible management public policy trends; and reviews the annual sponsorships, collaboration on industry of forests, and work with WWF’s Forests Sustainable Impact Report. The Committee The Sustainable Impact Steering Committee, initiatives, customer and supplier education, Forward, the Forest Stewardship Council®, receives regular updates on Sustainable Impact composed of representatives from across HP’s supplier capability-building programs, and our suppliers to ensure the fiber we use is strategy, metrics, results, and key risks and business units and global functions, provides supplier audits and assessments, conference responsibly sourced. See Renewable materials. opportunities. The NGSR Committee provides additional oversight and helps manage progress participation, employee surveys, mentoring, • Human rights—supply chain: We engage in guidance, and in some cases approval, on against our goals. and more. Appropriate stakeholders are multi-stakeholder collaborations, including the strategic priorities and investments. As disclosed identified based on factors such as expertise, Responsible Business Alliance, Leadership in our 2022 proxy statement, several members willingness to collaborate, reputation, location, Group for Responsible Recruitment, and Global sphere of influence, and ability to scale and Business Initiative for Business and Human accelerate progress. Rights, to drive progress and elevate supply 11 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix chain best practices. See Human rights and ESG materiality Supply chain responsibility. • Digital divide: We partner with UN Women and We periodically conduct ESG materiality Based on these inputs, we evaluated and ranked Girl Rising to advance education for women assessments to review relevant ESG topics, Approach topics, then validated the results in a workshop and girls, and we work with MIT Solve and NABU reconfirm our long-standing areas of focus, and with HP executives and experts. Our new 2021 to advance digital literacy in communities clarify and shape our Sustainable Impact In 2021, we engaged the sustainability consultancy ESG materiality matrix summarizes the outcome around the world. See Education. strategy, investments, and disclosures. This Environmental Resources Management (ERM) of this process. process enables us to focus our efforts on the to conduct an ESG materiality assessment. Many other examples of HP’s stakeholder areas where we can have the greatest impact, Through interviews, surveys, and other sources, engagement are included throughout this report. determine gaps in our approach, and identify we collected internal and external input on a Key findings trends and leadership opportunities for our wide range of topics to determine their relative business. ESG materiality assessment informs importance to HP and to external stakeholders, By integrating a broad range of inputs and fresh our goals-setting process, and we have set and to understand the degree of impact we insights, our new ESG materiality assessment 1 aggressive goals related to several of our most can have on each topic area. Prior to this, our reflects the rapidly evolving landscape of ESG ESG-material topics to manage performance and most recent ESG materiality assessment was topics. In some cases, we combined topics or drive long-term progress. conducted in 2019. refined names or definitions to better reflect topic We collected input from a broad range of scope or content, and digital divide emerged as a stakeholders—including HP employees and new topic during the assessment. Throughout this report, we use the definition executives, customers, suppliers, investors, In addition to determining HP’s ESG material of “materiality” from the GRI (Global Reporting NGOs, and peer companies—to reflect a diverse topics, several key themes emerged: Initiative) Standards, which is different from range of views. To better understand HP’s the term as it has been defined by or construed impacts and potential impacts related to each • It is critical to take aggressive near-term action in accordance with the securities laws or any topic, the process incorporated the Future Fit on decarbonization, including by engaging other laws of the United States or any other Benchmark Technology Sector Impact Areas and suppliers to reduce climate impact throughout jurisdiction, or as used in the context of our Sustainable Development Goals Sector Survey. HP’s value chain. financial statements and financial reporting, The assessment also took into account leading • Stakeholders increasingly expect transparent or our reports filed with the U.S. Securities and reporting frameworks such as the GRI Standards reporting on carbon footprint and related Exchange Commission. Topics identified as ESG for sustainability reporting and the Sustainability impacts, risks, and opportunities, as well as material for the purpose of this report should Accounting Standards Board (SASB) Technology robust social impact data and metrics across not be construed as being material for SEC or & Communications Hardware Standard. the value chain. other financial reporting purposes. 12 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix • HP has the potential to expand social and environmental value HP 2021 ESG materiality matrix creation beyond the value chain, including by advocating for policy related to Climate Action, Human Rights, and Digital Equity. Areas of focus • HP has an opportunity to lead our industry toward a more circular Climate Action economy through closed-loop manufacturing, service-based 3D HIGH Decarbonization Circular printing, and robust reuse, repair, and recycling programs. Human rights: supply chain economy Human Rights • Human rights remain a key focus for customers, policymakers, Digital Equity and investors. Companies are expected to address related risks Climate change Governance resilience and opportunities across their value chains, including through Public policy cross-industry collaboration with suppliers and business partners. engagement Human rights: s operations and Degree of impact HP • The digital divide is growing, and HP has an opportunity to downstream can have on topics collaborate with civil society, governments, and others to eholder Digital accelerate digital equity, particularly in the areas of work, ak Human capital divide High education, and healthcare. t Diversity, equity, Medium ernal s Data and and inclusion Low t ESG materiality matrix x product e Community Packaging security o Corporate Paper and forests t Our 2021 ESG materiality matrix maps topics by relative importance investment and governance involvement Transparency to HP’s business success and to external stakeholders, while also ance Product and t Ethics and and reporting summarizing the company’s impact in each area. Topics above the operational health anti-corruption diagonal are considered ESG material for the purpose of this report. impor and safety Privacy Items below the ESG materiality threshold are not covered in as e Biodiversity Water Product energy efficiency much detail, but remain important to HP. elativ R Our ESG material topics list includes definitions, corresponding Future of work GRI Standards Topics, and boundaries for each topic. W LO Relative importance to HP 13 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Footprint 15 Carbon and climate impact 16 Water 17 Data 14 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

This is a modal window.

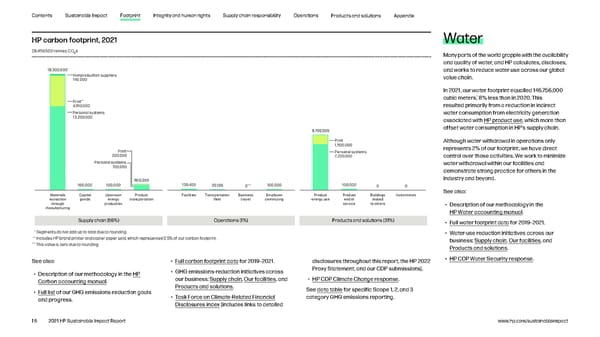

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix The manufacturing, delivery, and use of HP Carbon and climate impact products and solutions requires a substantial amount of natural resources and energy use. Our carbon and water footprints cover our We strive to reduce the climate impact of our to product transportation. This reduction was While GHG emissions from our operations only 1 supply chain, operations, and products and driven in part by the increased energy efficiency represent 1% of our footprint, we work to entire global value chain, from suppliers to our operations and millions of customers worldwide. solutions. HP’s carbon footprint in 2021 equaled of our products as well as the continued impact demonstrate leadership in emissions management, We were the first global IT company to publish 28,459,500 tonnes of carbon dioxide equivalent of COVID-19 on sales of different product lines, reduction, and disclosure. Our global operations a full carbon footprint, and one of the first to (CO2e), 3% less than in 2020. An 11% decrease particularly a shift toward Chromebooks, other produced 159,500 tonnes of Scope 1 and Scope 2 disclose a complete water footprint. We continue in GHG emissions associated with product notebooks, and inkjet printers, which tend to be COe emissions during 2021, a 7% decrease 2 to measure and manage our environmental use more than offset a 3% increase related to lighter and are more energy efficient than desktop compared to 2020. footprint across the value chain, always pursuing product manufacturing and a 13% rise related PCs and LaserJet printers. areas for improvement. Transforming HP to help drive a more efficient, circular, and net zero carbon economy is central 2030 AND 2040 GOALS METHODOLOGICAL UPDATES to our Sustainable Impact strategy. Reduce HP value chain GHG emissions by This report reflects several methodological updates to improve the accuracy of our carbon HP has achieved triple “A” scores for transparency 50% by 2030 (compared to 2019), and achieve footprint calculations and to align with our 2030 GHG emissions-reduction goal. These include: and action on climate, forests, and water for net zero emissions by 20401 several consecutive years, and has also been • Personal systems: Using a new life cycle assessment (LCA) tool, which allows for updated and recognized as a CDP Supplier Engagement PROGRESS IN 2021 refined modeling based on HP-specific parameters, to calculate GHG emissions associated Leader. See Recognition. HP’s carbon footprint of 28,459,500 tonnes of with personal systems. COe in 2021 was 2 • Paper: Using the tonnage of HP brand paper sold during the year to calculate associated GHG emissions, and not including GHG emissions associated with non-HP brand paper used in HP 9% printers. These emissions are now included in Scope 3 category 1 instead of category 11. This aligns with guidance regarding indirect use-phase GHG emissions associated with product use less than in 2019, primarily due to reductions from the GHG Protocol and the Science Based Targets initiative (SBTi). related to product use resulting from increased • Nonproduction suppliers: Adding GHG emissions associated with nonproduction suppliers, energy efficiency and changes to the mix of based on data provided by those suppliers. Learn more. products sold. See additional GHG emissions-reduction goals. Based on our updated methodology, we have restated GHG emissions data for 2019 and 2020, for comparability. These methodological updates impact Scope 3 categories 1, 4, 9, 11, and 12. 15 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix HP carbon footprint, 2021 Water 28,459,500 tonnes CO2e Many parts of the world grapple with the availability and quality of water, and HP calculates, discloses, 18,300,000* and works to reduce water use across our global ƒonproduction suppliers value chain. 10,000 In 2021, our water footprint equalled 146,756,000 1 ** cubic meters, 8% less than in 2020. This Print ,910,000 resulted primarily from a reduction in indirect Personal systems water consumption from electricity generation 13,00,000 associated with HP product use, which more than 8,€00,000 offset water consumption in HP’s supply chain. Print Although water withdrawal in operations only 1,‚00,000 represents 2% of our footprint, we have direct Print Personal systems 00,000 €,00,000 control over those activities. We work to minimize Personal systems water withdrawal within our facilities and €00,000 demonstrate strong practice for others in the 900,000 industry and beyond. 100,000 100,000 139,00 0,100 0*** 100,000 100,000 0 0 Materials Capital Upstream Product Facilities ransportation usiness mployee Product Product uildings nestments See also: extraction goods energy transportation fleet trael commuting energy use end of leased through production serice to others • Description of our methodology in the manufacturing HP Water accounting manual. Supply chain (68%) Operations (1%) Products and solutions (31%) • Full water footprint data for 2019–2021. * Segments do not add up to total due to rounding. • Water-use reduction initiatives across our ** Includes HP brand printer and copier paper sold, which represented 0.5% of our carbon footprint. business: Supply chain, Our facilities, and *** This value is zero due to rounding. Products and solutions. See also: • Full carbon footprint data for 2019–2021. disclosures throughout this report, the HP 2022 • HP CDP Water Security response. • GHG emissions-reduction initiatives across Proxy Statement, and our CDP submissions). • Description of our methodology in the HP our business: Supply chain, Our facilities, and Carbon accounting manual. • HP CDP Climate Change response. Products and solutions. See data table for specific Scope 1, 2, and 3 • Full list of our GHG emissions-reduction goals category GHG emissions reporting. and progress. • Task Force on Climate-Related Financial Disclosures index (includes links to detailed 16 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Data Carbon footprint (Scopes 1–3)* 2019 2020 2021 2019 2020 2021 GHG emissions from operations** Refrigerants (hydrofluorocarbons (HFCs))††, ††† 1,100 2,100 1,900 [tonnes CO2e] 215,800 171,000 159,500 Americas 49,600 41,000 39,000 Americas 100 100 0 Europe, Middle East, and Africa 57,900 48,100 47,300 Europe, Middle East, and Africa 1,000 2,000 1,900 Asia Pacific and Japan 108,300 81,900 73,200 Asia Pacific and Japan 0 0 0 *** Perfluorocarbons (PFCs)††† 3,500 2,800 3,700 GHG emissions intensity [tonnes CO e/US$ million of net revenue] 3.7 3.0 2.5 2 GHG emissions by scope [tonnes CO e] Americas 3,500 2,800 3,700 2 Europe, Middle East, and Africa 0 0 0 Scope 1 Asia Pacific and Japan 0 0 0 Scope 1 emissions, by region 61,900 50,600 48,700 Carbon dioxide (CO )††† 57,100 45,700 43,100 Americas 47,100 39,400 38,800 2 Nitrous oxide (N O)††† 200 0 0 Europe, Middle East, and Africa 13,400 10,600 9,200 2 Methane (CH )††† 100 0 0 Asia Pacific and Japan 1,400 600 700 4 Scope 2 (market-based method)†††† Scope 1 emissions, by type Scope 2 emissions, by region 153,900 120,400 110,800 Natural gas 23,800 21,400 22,700 Americas 2,500 1,600 200 Americas 20,500 19,300 20,700 Europe, Middle East, and Africa 44,500 37,500 38,100 Europe, Middle East, and Africa 2,200 1,800 1,700 Asia Pacific and Japan 106,900 81,300 72,500 Asia Pacific and Japan 1,100 300 300 Scope 2 emissions, by type 153,900 120,400 110,800 Diesel/gas/oil/LPG**** 200 300 300 Purchased electricity for operations 152,900 119,600 110,100 Americas 200 200 100 Americas 2,500 1,600 200 Europe, Middle East, and Africa 0 0 0 Europe, Middle East, and Africa 44,500 37,500 38,100 Asia Pacific and Japan 0 100 200 Asia Pacific and Japan 105,900 80,500 71,800 Transportation fleet† 33,300 24,000 20,100 District cooling and heating (purchased) for operations 1,000 800 700 Americas 22,800 17,000 14,300 Americas 0 0 0 Europe, Middle East, and Africa 10,200 6,800 5,600 Europe, Middle East, and Africa 0 0 0 Asia Pacific and Japan 300 200 200 Asia Pacific and Japan 1,000 800 700 17 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix 2019 2020 2021 2019 2020 2021 Scope 2 (location-based method) Franchises (category 14) N/A N/A N/A Scope 2 emissions, by region 226,400 203,600 198,200 Investments (category 15) De minimis De minimis De minimis Americas 67,100 60,700 55,600 * To calculate Scope 1, Scope 2, and Scope 3 emissions, HP has followed the principles outlined in the Greenhouse Gas Protocol. Europe, Middle East, and Africa 48,300 44,900 44,700 Additional details on calculations and methodology can be found in the HP Carbon accounting manual. Scope 1 GHG emissions include CO, CH , N O, HFCs, and PFCs. No biogenic emissions are present in this category. Scope 2 GHG emissions include CO , CH , and N O. 2 4 2 2 4 2 Asia Pacific and Japan 111,000 98,000 97,900 No biogenic emissions are present in this category. Scope 3 GHG emissions: • Materials extraction through manufacturing (category 1), Transportation (categories 4 and 9), Product use (category 11), and Product Scope 2 emissions, by type 226,400 203,600 198,200 end of service (category 12) include CO , CH , N O, HFCs, PFCs, SF , and NF , and represented approximately 99% of our Scope 3 2 4 2 6 3 emissions in 2021. Biogenic emissions are present and captured in the paper emissions factor of HP paper manufactured (category 1). Purchased electricity for operations 225,400 202,800 197,500 • Capital goods (category 2) includes CO , CH , N Oand HFCs, and represented 0.35% of our Scope 3 emissions in 2021. 2 4 2 • Upstream energy production (category 3), Waste generated in operations (category 5), and Business travel (category 6) includes CO , Americas 67,100 60,700 55,600 CH andN O, and represented 0.35% of our Scope 3 emissions in 2021. 2 4 2 Europe, Middle East, and Africa 48,300 44,900 44,700 • Employee commuting (category 7), Buildings leased to others (category 13), and Investments (category 15) include CO2, and Asia Pacific and Japan 110,000 97,200 97,200 represented 0.35% of our Scope 3 emissions in 2021. • Upstream leased assets (category 8), processing of sold products (category 10), and franchises (category 14) are not applicable to HP. ** District cooling and heating (purchased steam) for operations 1,000 800 700 Total includes HP’s reported values for Scope 1 and Scope 2 market-based method emissions in table. *** Emissions-intensity values were calculated using HP’s annual revenue as characterized in financial reporting and Scope 1 and Scope 2 Americas 0 0 0 GHG emissions. Europe, Middle East, and Africa 0 0 0 **** HP does not estimate or extrapolate diesel use for nonreporting sites. † CO e emissions associated with CH and N O account for less than 1% of total CO e emissions in this category, Asia Pacific and Japan 1,000 800 700 2 4 2 2 †† HP collects all refrigerant consumption data from local facility maintenance teams company-wide, directly accounting for facilities’ ^ refrigerant leakage and use and avoiding the need for extrapolation. We use various tools and sources for global warming potential and Scope 3 [tonnes CO e] 31,170,000 29,020,000 28,300,000 2 ozone depletion values, including the Greenhouse Gas Protocol’s GHG Emissions from Refrigeration and Air Conditioning tool, IPCC Materials extraction through manufacturing (category 1; 18,300,000 17,900,000 18,300,000 Second Assessment Report (1995). ††† The total for 2019 of refrigerants, PFCs, CO , N O, and CH varies by less than 1% from Scope 1 emissions, by region, due to rounding. also see Greenhouse gas emissions on page 36) 2 2 4 †††† Data in this section uses the market-based method. Due to the availability and feasibility of acquiring the data, the company only Capital goods (category 2) 300,000 100,000 100,000 obtained utility-specific emission factors for its sites in Glasgow, Scotland; León and Madrid, Spain; and Palo Alto and San Bernardino, California; Boise, Idaho; Indianapolis, Indiana; Albuquerque, New Mexico; and Socorro, Texas, in the United States. Upstream energy production (category 3)^^ 100,000 100,000 100,000 ^ See Methodological updates on page 15. ^^^ ^^ Transportation (categories 4 and 9; also see Product transportation on page 37) 800,000 800,000 900,000 Scope 2 GHG emissions used to calculate this category were determined using the location-based method. ^^^ This product transportation data is based on LCA-based estimates. It uses a combination of HP-specific and industry data, and includes Waste generated in operations (category 5) De minimis^^^^ De minimis De minimis additional upstream and downstream transportation related to our products. This data may differ from data reported by product Business travel (category 6)‡ 70,000 20,000 De minimis transportation suppliers that HP contracts to deliver our products, as presented on pages 37 and 44. ^^^^De minimis values are less than 0.25% of total Scope 3 emissions. ‡ Employee commuting (category 7) 200,000 200,000 100,000 HP’s global travel agency provides values that take into account the type of aircraft, passenger load, cabin class, and miles traveled for each ticketed trip. This data also includes rail travel carriers and distance traveled. Although these values fall below our quantitative Upstream leased assets (category 8)‡‡ N/A N/A N/A reporting threshold of 0.25% of total Scope 3 emissions and could be reported as de minimis, we choose to report this category due to Processing of sold products (category 10) N/A N/A N/A our ability to directly track this data, our level of influence over these emissions, and stakeholder expectations in this category. ‡‡ All facilities are accounted for in Scope 1 and 2. Leased furniture and equipment are included in Capital goods (category 2). ‡‡‡ ‡‡‡ Product energy use (category 11) 11,300,000 9,800,000 8,700,000 Scope 3 emissions from inkjet and LaserJet printers that HP manufactures for sale and service by other original equipment manufacturers are excluded from our carbon footprint. In 2021, these printers represented less than 5.3% of HP printers manufactured Product end of service (category 12) 100,000 100,000 100,000 in the reporting year, and consequently, their associated emissions represented less than 6.5% of the product life cycle emissions of all Buildings leased to others (category 13) De minimis De minimis De minimis HP-manufactured printers. Scope 1 and 2 emissions from the manufacturing of these printers at HP-operated facilities is captured in the Scope 1 and 2 data reported in this year’s report. 18 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Water footprint* 2019 2020 2021 Water consumption in HP supply chain—direct use in operations** [cubic meters] 19,700,000 18,500,000 20,200,000 Water consumption in HP supply chain associated with the generation of electricity 40,000,000 38,400,000 43,000,000 [cubic meters] Water withdrawal in HP operations [cubic meters] 2,930,000 2,597,000 2,556,000 Water withdrawal associated with the generation of electricity used in HP operations 2,300,000 2,100,000 2,100,000 [cubic meters] Water consumption associated with the generation of electricity used by HP 103,600,000 97,600,000 78,900,000 *** products [cubic meters] * Methodological updates to improve the accuracy of our carbon footprint calculations also impacted calculations in the following water footprint categories: water consumption in HP supply chain—direct use in operations, water consumption in HP supply chain associated with the generation of electricity, and water consumption associated with the generation of electricity used by HP products. Please see Methodological updates on page 15 for more detail. Some data for 2019 and 2020 are restated as a result. Additional details on calculations and methodology can be found in the HP Water accounting manual. ** This metric reports the amount of water consumed by HP’s multi-tier supply chain, and not the amount withdrawn by first-tier suppliers as reported on page 38. Because water withdrawn can also be returned, water consumption is inherently lower. *** Indirect water consumption from inkjet and LaserJet printers that HP manufactures for sale and service by other original equipment manufacturers is excluded from our water footprint. In 2021, these printers represented less than 5.3% of HP printers manufactured in the reporting year, and consequently, their associated indirect water consumption during product use represented less than 6.6% of the product life cycle water consumption of all HP-manufactured printers. Water consumption from the manufacturing of these printers at HP-operated facilities is captured in the direct water consumption data reported in this year’s report. 19 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Integrity and human rights 21 Ethics and anti-corruption 25 Privacy 23 Human rights 27 Public policy 20 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Ethics and anti-corruption We expect everyone at HP to meet the highest aware of their responsibilities in reinforcing HP’s Ethics and compliance governance at HP ethical standards and to treat others with integrity, commitment to ethical behavior. During 2021, all respect, and fairness. A strong commitment to members of HP’s Board of Directors received our values underpins our efforts, reinforced by Integrity at HP content relevant to their positions, in-depth training and communication, and upheld and certified that they had read it. Board of Directors through targeted policies and strong governance. The Board of Directors is responsible for overseeing ethics and compliance at HP. Chip Bergh is the Chairman. Conducting business with integrity is central Regular training, newsletters, and virtual coffee All members are independent directors, excluding Enrique Lores, president and chief executive officer, HP Inc. to HP’s culture. In 2022, our commitment was talks help to reinforce the values and content recognized for the third consecutive year when outlined in Integrity at HP. Employees can also HP was named one of the World’s Most Ethical access Integrity Central, a comprehensive library Board of Directors Audit Committee Ethics and Compliance Committee Companies® by Ethisphere. of ready-to-use material on key ethics topics, with Provides non-executive input and guidance Composed of HP executives and provides oversight toolkits, posters, infographics, training materials, to the Ethics and Compliance Office. and guidance on the design and implementation of HP is committed to complying with all applicable and scenarios. In 2021, the Ethics Office continued our ethics and compliance program. laws and regulations everywhere we operate. We to expand the content available in Integrity also require ethical conduct by our suppliers and Central, growing the library of translated training Ethics and Compliance Office partners and use our scale and influence to drive courses, videos, posters, and infographics. (within Global Legal Affairs) progress across the broader IT industry. See Manages ethical issues across our global operations. Specific responsibilities include oversight of Integrity Human rights and Supply chain responsibility. at HP, coordination of the company’s Compliance Assessment Program, management of anti-corruption ONGOING GOAL and privacy, and the design and management of processes that prevent, mitigate, and remediate all related Ethics business impacts. Maintain greater than 99% completion rate of annual Integrity at HP training among active HP Training and communication employees and the Board of Directors See governance information online, including the in-country 24-hour toll-free phone lines with PROGRESS IN 2021 board’s composition, committees, and charters, translation, text messaging (in the United States), The annual training on Integrity at HP—our as well as our company bylaws and Corporate mail, and in person. We offer anonymous employee code of conduct—covers key policies, Governance Guidelines. reporting options where allowed by law. At any procedures, and high-risk issues that employees time, employees can also reach out to their might face, and incorporates scenarios based 99.2% Reporting concerns manager or another leader under HP’s Open Door on actual investigations. Each year, HP requires of employees, including senior executives, Policy, seek advice from internal ethics and all employees to complete this training, including completed Integrity at HP training, as well as all We make it easy for our employees and third compliance experts, or consult Internal Audit, content on anti-corruption, conflicts of interest, members of the Board of Directors1 parties to ask questions and report ethics Human Resources, local Integrity at HP teams, or accurate business records, and anti-retaliation. concerns about the broad range of ESG issues. Integrity at HP liaisons. HP does not tolerate Additionally, the training includes manager- Reporting avenues are available to 100% of retaliation against anyone who raises a concern specific content to ensure that managers are employees and include an online form, global or question. 21 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Items reported to global Integrity When appropriate, representatives from our Risk assessment and audits Third-party management Legal, Controllership, and Human Resources HP conducts regular internal assessments of and due diligence at HP team or other compliance teams (including dedicated Employee Relations corruption-related risks across 100% of our functions in 2021 investigators from Human Resources) conduct HP performs ongoing risk-based due diligence local investigations. Escalated allegations are global operations, including detailed reviews of of third parties that support our business, percentage of total investigated by a dedicated global Integrity the company’s global policies and processes including channel partners, sales intermediaries, Total number of reported items in 2021: 123 investigations team. HP’s investigation process applicable to all business units and global suppliers, and lobbyists. We communicate HP’s continues to evolve, with improved resources functions worldwide. We also use internal data anti-corruption standards and requirements to 2021 and technology to perform investigation-related and Transparency International’s Corruption 100% of these third parties through contractual functions in-house and to respond promptly Perceptions Index (CPI) to identify high-risk terms and conditions as well as our Partner Code Human resources 30% regions and assess risks related to our business. of Conduct and Supplier Code of Conduct. HP to concerns. Additionally, our global case Anti-corruption* 5% management tool enables us to identify emerging The public sector data analytics tools and requires all partners and suppliers, respectively, Misuse of assets 17% trends in ethics violations and to assess where processes we adopted in 2019 have enhanced to comply with our Partner and Supplier Codes additional controls may be needed. HP’s ability to monitor and mitigate potential risk of Conduct. Fraud 15% from its public sector business. These tools are Theft 5% subject to regular review and improvement to HP has implemented and maintains a robust risk- Brand protection/channel 7% Anti-corruption enhance the quantity and quality of available data. based legal and regulatory due diligence program to detect, mitigate, and prevent third-party anti- Conflicts of interest 8% We also periodically retain outside experts to corruption compliance risks and violations. Inaccurate records 11% Corruption disrupts fair competition, and is assess our anti-corruption policies and programs. at odds with HP values. We do not tolerate We benchmark our approach against peer We determine risk levels based primarily on Competition 2% corrupt behavior of any kind, including bribery companies to identify best practices in areas completion of our due diligence questionnaire Total 100% and kickbacks. including operational procedures, employee by the third party (every three years, for existing education, and supplier and partner training partners and suppliers) as well as the country- * Includes allegations of commercial bribery, kickbacks, and Our Anti-Corruption Policy and compliance and monitoring. level CPI. Based on these items, HP decides Global Business Amenities Policy violations, as well as alleged program require our employees, partners, corruption related to foreign public officials. and suppliers to follow all applicable national whether to conduct an additional due diligence laws and regulations, including the U.S. Foreign Complementing these assessments, HP conducts investigation. If we determine that the risk Investigating concerns Corrupt Practices Act and the UK Bribery Act. regular audits focused on potential corruption cannot be mitigated, we apply consequences to Although HP is not certified to an anti-corruption risks in our operations. These audits include end- the relevant third party by removing access to Suspected violations of Integrity at HP damage management system, all of our operational to-end review and testing of compliance policies specific benefits and/or terminating any contract trust in our company. We take all alleged violations sites and subsidiaries are required to follow and processes. with HP. seriously, ensure responses are timely, and take HP’s Anti-Corruption Policy and are subject disciplinary or remedial actions when appropriate, Potential corruption risks are reviewed using HP HP requires third parties to complete due including coaching, written warnings, and, in serious to HP’s compliance program and procedures transactional data and third-party corruption diligence on a predetermined basis. In general, cases, termination. Serious violations may impact (or a comparable subsidiary-level policy and assessments. The Anti-Corruption team may then all channel partners must complete this process an employee’s Total Rewards package (subject to compliance program). take various actions to appropriately minimize or before beginning a contractual relationship with local labor laws and where legally permissible). eliminate identified risk. This can include termination HP and then undergo a renewal process at least of partner contracts or special handling measures. 22 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix once every three years. Third parties receive Human rights training as part of HP’s due diligence process. Training and communication HP’s stance on human rights is clear and and data protection, accessibility, and unintended purposes or in contexts that create uncompromising. We embrace our responsibility environmental sustainability. adverse human rights impacts. We deliver comprehensive anti-corruption to respect human rights, continually monitoring content to all employees through annual Integrity emerging human rights expectations and Our policy commitment includes respecting We sell PCs and printers to consumers, at HP training, as well as to all members of best practices. human rights in accordance with the United businesses, and governments worldwide. These the Board of Directors. We also communicate Nations Guiding Principles on Business and products and technologies are widely available in year-round with our employees to reinforce our Human Rights (UNGPs) and the Organisation the market from HP and its competitors. To avoid policies, controls, and training. Approach for Economic Co-operation and Development the misuse of our products and solutions, HP is (OECD) Guidelines for Multinational Enterprises. committed to complying with all relevant sanctions, Additionally, targeted employee training is We are committed to ensuring that everyone We commit to respect internationally recognized restrictions, and embargoes imposed by national provided to cover specific anti-corruption within HP and throughout our value chain is human rights as expressed in the: governments or international organizations across risks relevant to business functions, roles, and treated with dignity and respect. We insist that all our worldwide operations. In all of our business, responsibilities. In 2021: workers are treated fairly and have safe working • International Bill of Human Rights, meaning we prioritize the highest standards of corporate conditions and freely chosen employment. the Universal Declaration of Human Rights, the ethics, and we operate in strict accordance with all • Over 13,100 employees (99% of the employees International Covenant on Civil and Political applicable laws and regulations. assigned) who support HP’s public sector Policies and commitments Rights, and the International Covenant on business or work in higher-risk jobs completed Economic, Social and Cultural Rights. When we identify potential human rights risks this training. Of these, 33% were in the In 2021, HP strengthened its Human Rights Policy • International Labour Organization’s Declaration within our value chain, we conduct human rights Americas, 35% in Asia Pacific and Japan, and (available in 24 languages), which advances our on Fundamental Principles and Rights at Work. due diligence. When others make allegations 32% in Europe, the Middle East, and Africa. commitment to upholding human rights, engaging linking our business to adverse human rights with rights holders, and embedding our approach In addition, we continue to support the Ten impacts, we investigate the claims in line with • About 3,390 employees (92% of the relevant throughout our business and value chain. This Principles of the United Nations Global Compact. our Human Rights Policy. Wherever we can employee base) completed training on the policy and our Sustainable Impact strategy exert influence to mitigate alleged human rights requirements for doing business with the recognize that social and environmental issues We also commit to comply with local laws and impacts we do so. U.S. government. are interconnected, and many have human rights regulations. Where laws are silent as to protected dimensions. We work for holistic change across a human rights or are less stringent than our Governance and accountability Due to COVID-19-related travel restrictions during approach, we work diligently to develop solutions the year, these trainings were conducted virtually. broad range of areas. to advance our commitment, supporting progress Our President and Chief Executive Officer, who We have developed specialized policies wherever possible. is also a member of our Board of Directors, Requirements for mitigating anti-corruption approved our Human Rights Policy, and our risk associated with charitable giving are and practices to support our human rights communicated to employees through the HP commitments, including those addressing Technology and human rights Head of Corporate Affairs holds operational Global Charitable Contributions Policy, and risks supply chain responsibility, responsible Technology has the potential to improve the accountability for this policy. The Head of are mitigated through the grantmaking process. minerals sourcing, human resources, diversity, lives of people around the world. However, we Corporate Affairs, Chief Supply Chain Officer, equity, and inclusion, racial equality, privacy recognize that technology can also be used for and Chief People Officer are responsible for 23 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix human rights across HP. The company operates Human rights due diligence In late 2021, we engaged external human rights The scope of on-site audits and specialized an internal Human Rights Council to further experts to assist us in governance assessment assessments depends on the nature of the promote the integration of our Human Rights Building on our knowledge and capabilities, and and a global human rights risk assessment. The work performed by the entity and the nature of Policy. The Council is chaired by an HP executive in line with the UN Guiding Principles on Business process, which is ongoing, will include reviewing the prioritized risks. For most of our production who has performance incentives to manage and Human Rights, we are responding to new stakeholder concerns across our sector, suppliers, we conduct full audits against our the company’s human rights program. The challenges, assessing risks, and monitoring engaging with potentially affected stakeholders Supplier Code of Conduct. For nonproduction Council is informed by independent external our performance. Progress includes being and civil society organizations, and reviewing suppliers, we may conduct audits only covering human rights experts. Board-level oversight is transparent about issues we face and discover, policies and procedures with reference both those portions of the Supplier Code of Conduct provided by the Nominating, Governance and and how we are resolving them. We practice to proposed human rights laws and to how our that are relevant to their operations. Social Responsibility Committee of HP’s Board human rights due diligence across our business voluntary commitments align to the UN Guiding of Directors. on our salient human rights issues (starting with Principles on Business and Human Rights and the Grievance mechanisms our own operations) including identification, UN Sustainable Development Goals. Training We offer multiple channels for our employees and investigation, prevention, and mitigation of The assessments will help us identify our priority third parties, such as workers in our supply chain, 1 adverse human rights impacts that the business human rights risks across our value chain, assess to ask questions and report concerns. We do not In 2021, 99.2% of employees (including senior executives) completed annual Integrity at HP may cause or contribute to through its own the ability of our policies and procedures to tolerate retaliation against those who engage training, which typically includes some human activities, or which may be directly linked to encompass new expectations and requirements, in our grievance processes, and we expect the rights-related content. For Human Rights Day on our operations, products, or services by our and inform creation of a tailored action plan to same from our business partners. December 10, 2021, we released an employee business relationships. help drive further enhancements to our human awareness video explaining human rights and rights efforts. We plan to share highlights when We collaborate to provide access to effective why they matter, as well as highlighting our legacy Risk assessment our evaluation is finalized. remedy and monitor reported grievances, of respecting human rights at HP. regardless of source, through to resolution. We Our human rights due diligence process is Audits and assessments also track and assess allegations of potentially Disclosures structured to identify and address human rights adverse human rights impacts that are brought risks and impacts across our value chain. Given We use audits and specialized assessments to to our attention outside of the grievance process, In addition to our Sustainable Impact Report, HP’s large global footprint, prioritization is critical help assess performance and identify corrective and take appropriate actions when allegations we also publish the HP Modern Slavery to the program’s effectiveness. We prioritize action where required. Use of audits and are confirmed. Learn more. Transparency Statement. risks based on salience—the severity and assessments is prioritized by level of risk. As a likelihood of adverse impacts on stakeholders we member of the Responsible Business Alliance might affect directly or indirectly. We strive to (RBA), we base our Supplier Code of Conduct continually improve our program by expanding on the RBA Code of Conduct and use the RBA responsible business conduct, ceasing, Validated Audit Process and Audit Protocol. preventing, or remedying the impact, and We only use certified auditors, and most audits reporting on implementation and results. are conducted by third-party auditing firms. 24 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact