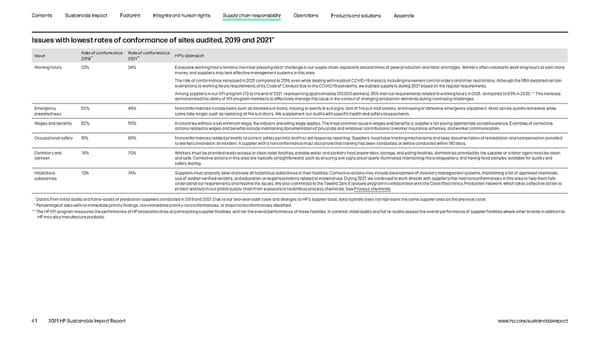

Contents Sustainable Impact Footprint Integrity and human rights Supply chain responsibility Operations Products and solutions Appendix Issues with lowest rates of conformance of sites audited, 2019 and 2021* Issue Rate of conformance Rate of conformance HP’s approach 2019** 2021** Working hours 22% 24% Excessive working hours remains the most pressing labor challenge in our supply chain, especially around times of peak production and labor shortages. Workers often voluntarily work long hours to earn more money, and suppliers may lack effective management systems in this area. The rate of conformance increased in 2021 compared to 2019, even while dealing with residual COVID-19 impacts, including movement control orders and other restrictions. Although the RBA declared certain exemptions to working hours requirements of its Code of Conduct due to the COVID-19 pandemic, we audited suppliers during 2021 based on the regular requirements. *** Among suppliers in our KPI program (73 at the end of 2021, representing approximately 100,600 workers), 95% met our requirements related to working hours in 2021, compared to 93% in 2020. This increase demonstrated the ability of KPI program members to effectively manage this issue in the context of changing production demands during continuing challenges. Emergency 52% 49% Nonconformances include items such as blocked exit doors, missing or poorly lit exit signs, lack of fire exit instructions, and missing or defective emergency equipment. Most can be quickly remedied, while preparedness some take longer, such as replacing all fire exit doors. We supplement our audits with specific health and safety assessments. Wages and benefits 62% 55% In countries without a set minimum wage, the industry prevailing wage applies. The most common issue in wages and benefits is suppliers not paying appropriate social insurance. Examples of corrective actions related to wages and benefits include maintaining documentation of pay stubs and employer contributions to worker insurance schemes, and worker communication. Occupational safety 51% 65% Nonconformances related primarily to current safety permits and first aid response reporting. Suppliers must have tracking mechanisms and keep documentation of remediation and compensation provided to workers involved in an incident. A supplier with a nonconformance must also prove that training has been conducted, or will be conducted within 180 days. Dormitory and 74% 70% Workers must be provided ready access to clean toilet facilities, potable water, and sanitary food preparation, storage, and eating facilities; dormitories provided by the supplier or a labor agent must be clean canteen and safe. Corrective actions in this area are typically straightforward, such as ensuring exit signs are properly illuminated, maintaining fire extinguishers, and having food samples available for quality and safety testing. Hazardous 72% 74% Suppliers must properly label and store all hazardous substances in their facilities. Corrective actions may include development of inventory management systems, maintaining a list of approved chemicals, substances use of auditor-verified vendors, and education on legal restrictions related to material use. During 2021, we continued to work directly with suppliers that had nonconformances in this area to help them fully understand our requirements and resolve the issues. We also committed to the Toward Zero Exposure program in collaboration with the Clean Electronics Production Network, which takes collective action to protect workers in our global supply chain from exposure to hazardous process chemicals. See Process chemicals. * Data is from initial audits and full re-audits of production suppliers conducted in 2019 and 2021. Due to our two-year audit cycle and changes to HP’s supplier base, data typically does not represent the same supplier sites as the previous cycle. ** Percentage of sites with no immediate priority findings, non-immediate priority nonconformances, or major nonconformances identified. *** The HP KPI program measures the performance of HP production lines at participating supplier facilities, and not the overall performance of those facilities. In contrast, initial audits and full re-audits assess the overall performance of supplier facilities where other brands in addition to HP may also manufacture products. 41 2021 HP Sustainable Impact Report www.hp.com/sustainableimpact

HP Sustainable Impact Report Page 40 Page 42

HP Sustainable Impact Report Page 40 Page 42