Owens Corning Sustainability Report

BUILDING A SUSTAINABLE FUTURE 2021 SUSTAINABILITY REPORT

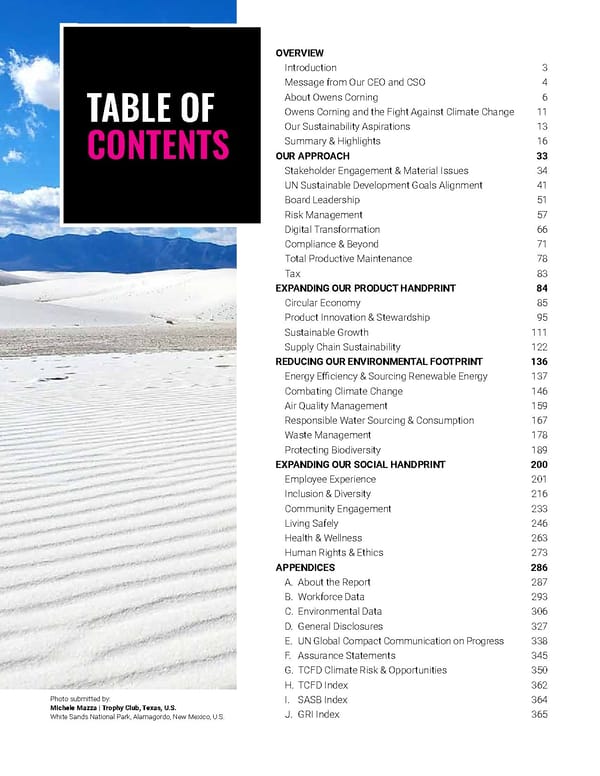

TABLE OF CONTENTS OVERVIEW Introduction Message from Our CEO and CSO About Owens Corning Owens Corning and the Fight Against Climate Change Our Sustainability Aspirations Summary & Highlights OUR APPROACH Stakeholder Engagement & Material Issues UN Sustainable Development Goals Alignment Board Leadership Risk Management Digital Transformation Compliance & Beyond Total Productive Maintenance Tax EXPANDING OUR PRODUCT HANDPRINT Circular Economy Product Innovation & Stewardship Sustainable Growth Supply Chain Sustainability REDUCING OUR ENVIRONMENTAL FOOTPRINT Energy Efficiency & Sourcing Renewable Energy Combating Climate Change Air Quality Management Responsible Water Sourcing & Consumption Waste Management Protecting Biodiversity EXPANDING OUR SOCIAL HANDPRINT Employee Experience Inclusion & Diversity Community Engagement Living Safely Health & Wellness Human Rights & Ethics APPENDICES A. About the Report B. Workforce Data C. Environmental Data D. General Disclosures E. UN Global Compact Communication on Progress F. Assurance Statements G. TCFD Climate Risk & Opportunities H. TCFD Index I. SASB Index J. GRI Index Photo submitted by: Michele Mazza | Trophy Club, Texas, U.S. White Sands National Park, Alamagordo, New Mexico, U.S. 3 4 6 11 13 16 33 34 41 51 57 66 71 78 83 84 85 95 111 122 136 137 146 159 167 178 189 200 201 216 233 246 263 273 286 287 293 306 327 338 345 350 362 364 365

2021 Owens Corning Sustainability Report | Overview | Introduction | 3 BUILDING A SUSTAINABLE FUTURE Thank you for your interest in Owens Corning and the sustainability efforts that are at the heart of our operations. This is our 16th annual report, and we hope you find it to be a valuable resource in understanding our all-encompassing approach to sustainability. Our theme this year is inspired by Owens Corning’s refreshed mission statement, which was adopted in 2021: Building a sustainable future through material innovation. Throughout this report, we demonstrate how we are working to fulfill that mission, as well as the many ways our people and our products are helping make the world a better place. Our emphasis on a sustainable future is especially appropriate this year, as this is the first report to be completely focused on our 2030 sustainability goals. This ambitious slate of objectives underscores our aspiration to be a net-positive company, one whose positive impacts far outweigh any negative impacts. Our sustainability goals are built on three key pillars: ■ Expanding our product handprint. We endeavor to increase the positive impacts our products have on the world. ■ Reducing our environmental footprint. We seek to limit the negative impact our operations have on the environment. ■ Increasing our social handprint . We work to safeguard people’s safety and help ensure that they live with health, happiness, and human dignity. The report is structured around 16 Sustainability Materiality Topics, which our stakeholders have indicated are most meaningful to them, and we have arranged the topics based on their relevance to these three pillars. We have prepared this report in accordance with the Global Reporting Initiatives (GRI) Comprehensive option. This is the more extensive option for GRI reporting, requiring additional disclosure related to our strategy, ethics and integrity, and governance. This report has been independently verified, including data and descriptions of all the ways our commitment to sustainability manifests itself. The chapters include explanations of our overall approach to each material topic, descriptions of the various initiatives we have in place to achieve our goals, and overviews of our progress to date. Additional supporting data can be found in the appendices at the end of the report, as well as indices reflecting information in response to the GRI standards, the United Nations Global Compacts (UNGC), Advanced- Level Communication on Progress, the Task Force on Climate-related Financial Disclosures (TCFD) and the Sustainability Accounting Standards Board (SASB) reporting requirements. Throughout the report, we also spotlight some of the employees who are helping to drive our efforts in each of our material topics. These Speaking of Sustainability interviews reveal the personal side of our endeavors and underscore the idea that our work in general — and our sustainability goals in particular — are global in scope and human in scale. Owens Corning is building a more sustainable future on a solid foundation, one that is based on years of successful innovation and dedication to our goals. As we continue to make progress on a new slate of goals — our most ambitious to date — we hope you will be inspired to join us on our sustainability journey. Photo submitted by: Yana Liu | Shanghai, China A view of Century Park, Shanghai.

2021 Owens Corning Sustainability Report | Overview | Message from our CEO and CSO | 4 A MESSAGE FROM OUR CEO AND CSO The foundation for our sustainability aspirations and our growth strategy is our mission — to build a sustainable future through material innovation. In 2021, our people thrived while persevering through continuing challenges and crises around the world that are changing social, political, and economic landscapes everywhere. We are extremely proud of our global Owens Corning team for their resolve and resiliency, which has enabled enduring sustainability progress in another demanding year. As we communicate each year, our aspiration is to be a net-positive company. In the pages of this document, our 16th annual sustainability reports, it’s our privilege to provide some highlights of our goals and approach, the progress we’ve made to date, and our work ahead. This 2021 report covers our efforts to double our products’ handprint and halve our environmental footprint, while concurrently working to eliminate injuries and lifestyle-induced diseases, advance inclusion and diversity, and collaborate to make a positive difference in the communities where we work and live. We began our sustainability journey nearly two decades ago, and along the way our goals have evolved, guided by the best available science. With the latest report from the Intergovernmental Panel on Climate Change affirming the need for urgent action, our science-based targets continue to inform our strategies and tactics from today to next week, next month, next year, and to 2030 and beyond. Like many companies around the world, Owens Corning faced headwinds in 2021. The continuing pandemic, supply chain disruption, inflation, and other headline-gr abbing events and influences all required innovation and adaptability for our business to succeed. At the same time, many of our manufacturing facilities were running at full capacity to continue to serve our customers. In 2021, as in any business environment, our 2030 sustainability goals helped us stay focused on the future while we navigated the present. We have established roadmaps to help our teams understand what’s needed to meet our environmental footprint reduction goals. These roadmaps guide our short-, mid-, and long-term strategies, and help ensure that sustainability remains our priority as we innovate to serve our customers while addressing both the challenges and the opportunities within the relevant secular trends. Among the trends that affect our markets, we see growth opportunities for Owens Corning in the increased premium of living spaces; changing construction practices due to labor shortages; demand for sustainable solutions for decarbonization and circularity; and investment in durable infrastructure. In fact, approximately 60% of our revenue comes from our portfolio of products that save energy or reduce emissions. These products have a role in energy efficiency improvements, housing renovation and construction, and increased renewable energy penetration — so the more we reduce our environmental footprint, the faster we achieve our net-positive aspiration. This dynamic drives our 2030 goal to cut our GHG emissions in half; this target has been verified by the Science Based Target initiative to be in line with the Intergovernmental Panel on Climate Change’s pathway to limit global warming to 1.5° Celsius maximum above pre-industrial levels. Concurrently, we have a science-based target of 30% reduction across our Scope 3 emissions that is also verified by SBTi. Photo submitted by: Kristin Bell | Toledo, Ohio, U.S. Rocky Mountain State Park, Colorado, U.S.

2021 Owens Corning Sustainability Report | Overview | Message from our CEO and CSO | 5 To achieve these goals, our roadmap for progress in climate change includes raw materials and processes with lower greenhouse gas emissions; increased recycled content/circularity; energy and process efficiency improvements; more renewable energy use; and fuel switching from on-site fossil fuel use to low- or no-carbon solutions. Long-term, we’ll be working to develop and implement last-mile solutions for operational emissions through innovation and exploration of still-emerging renewable fuel technologies. In 2021, we completed two power purchase agreements that add to our existing renewable electricity commitments. Sourcing 100% renewable electricity, another goal for 2030, is an important step toward our ambition to fully decarbonize. At the same time, we’re improving the efficiency of our operations to reduce energy use and working to reduce greenhouse gas emissions throughout the value chain of our products. Lowering the embodied carbon of our products further shortens the time it takes for them to save more GHG emissions in-use than are emitted to manufacture them. This is an example of the way trends, goals, and roadmaps for sustainability inform our business. Beyond environmental footprint reduction “within” our plants, we are working to refine our understanding and set measurable goals for our impact on biodiversity and the circular economy, as well as continually seeking better ways to measure our progress on social impact priorities like inclusion and diversity. In this report, you’ll find examples, data, and perspectives that represent our results and our plans. We are proud to have received external recognition for our sustainability commitments and results — including being the first company ever to earn the No. 1 spot on the 100 Corporate Best Citizens list from 3BL Media for three years in a row. In 2021, we were named to the Dow Jones Sustainability World Index for the 12th consecutive year, and we are also listed on the DJSI North America Index, with industry-leading assessment scores. Inclusion on these lists indicates that our overall approach to environment, social, and governance aspects of our business is aligned with stakeholder expectations. Other awards, such as our 17th consecutive perfect score for LGBTQ workplace equality on the Human Rights Campaign Foundation’s Corporate Equality Index, and our placement on CDP’s Water Security A List, help us gauge our progress on specific topics. Such accolades are an honor and acknowledge the work we’ve done, but they also spur us to do more. Our network of stakeholders has expanded rapidly in recent years, and we know that more people than ever are curious about our goals and interested in our results. Not long ago, ESG-labeled funds held 9% of our shares; today, that is 14%. As we grow, we also can have a larger effect on the communities and lives we touch. The progress we’ve made so far reflects our purpose: our people and products make the world a better place. Our 2021 results, detailed in this report, speak to the dedication and commitment of our people, and give us reason for optimism despite the challenges ahead. Sharing our results and aspirations is an important part of our commitment to all our stakeholders, and we are grateful for the many people who have inspired our work and pushed us to continually do more. Brian Chambers Chairman and Chief Executive Officer Frank O'Brien-Bernini Senior Vice President and Chief Sustainability Officer

2021 Owens Corning Sustainability Report | Overview | About Owens Corning | 6 ABOUT OWENS CORNING Owens Corning is a global building and construction materials leader committed to building a sustainable future through material innovation. Our three integrated businesses – Composites, Insulation, and Roofing – provide durable, sustainable, energy-efficient solutions that leverage our unique material science, manufacturing, and market knowledge to help our customers win and grow. Photo submitted by: Julie Pope | Toledo, Ohio, U.S. Owens Corning world headquarters. OUR MISSION To build a sustainable future through material innovation. OUR PURPOSE Our people and products make the world a better place. OUR VALUES Global in scope, human in scale. Caring: • We keep each other safe and healthy. • We offer an inclusive environment where diverse perspectives are valued and appreciated. • We actively support our communities and protect our environment. Curious: • We challenge the status quo for greater impact and innovation. • We listen and learn from one another’s different skill sets and experiences. • We relentlessly pursue solutions that exceed customer expectations. Collaborative: • We work together in an open, transparent and respectful way. • We foster highly connected teams across the global enterprise. • We partner with our customers and other stakeholders to drive the best outcomes. Committed: • We are accountable to deliver financial and operational results that outperform the market. • We empower our people to make decisions and act like owners. • We remain resilient to achieve our goals and best serve our purpose. THE OWENS CORNING STORY

2021 Owens Corning Sustainability Report | Overview | About Owens Corning | 7 Insulation Insulation products conserve energy while improving acoustics and fire resistance in the places where we work, live, and play. Our Insulation segment includes a diverse portfolio of high-, mid-, and low- temperature products; a market mix of residential, commercial, industrial, and other markets; and a channel mix of retail, contractor, and distribution. Our products in the residential channel — sold under well-recognized such well-known brand names and trademarks as Owens Corning ® PINK ® Fiberglas™ Insulation — include thermal and acoustical batts, loosefill insulation, and foam sheathing and accessories. In the commercial and industrial channel, our products are sold under well-recognized brand names and trademarks such as Thermafiber ® , FOAMGLAS ® , and PAROC ® insulation. They include glass fiber pipe insulation, energy efficient flexible duct media, bonded and granulated mineral wool insulation, cellular glass insulation and foam insulation used in above- and below- grade construction applications. We sell our insulation products primarily to insulation installers, home centers, lumberyards, retailers, and distributors in the U.S., Canada, Europe, Asia Pacific, and Latin America. Roofing Roofing products and systems protect and preserve homes and commercial buildings while enhancing curb appeal. Our primary products in the Roofing segment are laminate and strip asphalt roofing shingles. Other products in this segment include roofing components, synthetic packaging materials, and oxidized asphalt. Owens Corning ® shingles and roofing components are sold mainly through distributors, home centers, lumberyards, retailers, and contractors in the U.S., while our synthetic packaging materials are mainly used in the construction industry for lumber and metal packaging. Oxidized asphalt is a significant input used in the production of our roofing shingles. We are vertically integrated and have manufacturing facilities that process asphalt for use in our roofing shingle manufacturing. In addition, we sell processed asphalt to other shingle manufacturers, to roofing contractors for built-up roofing asphalt systems, and to manufacturers in other industries such as automotive, chemical, rubber, and construction. Composites Composite materials make products lighter, so less energy is needed to transport and operate them. They also help make products stronger and more durable, which reduces the need to repair or replace them. Our Composites business facilitates the manufacturing of a wide range of glass fiber and downstream products such as fabrics, nonwovens, and other specialized products. Composites are used in more than 40,000 end-use applications. We serve a range of market segments: building and construction, power and energy, industrial, and consumer products. Examples of end-use applications include pipe, roofing shingles, ladders, sporting goods, telecommunications cables, boat hulls, RV side panels, and wind energy blades. Owens Corning products are designed and engineered to provide a material difference for our customers and ultimately make the world a better place. Photos: Owens Corning ® products: PINK ® Next Gen™ Fiberglas™ Insulation (left) ProEdge ® Hip & Ridge Shingle (center) Fiberglas™ Rebar (right)

2021 Owens Corning Sustainability Report | Overview | About Owens Corning | 8 2021 Revenue by Segment 2021 Revenue by Region Composites 27% Insulation 36% Roofing 37% United States 67% Europe 16% Asia Pacific 9% Canada and Other 8% We aim to capitalize on our market-leading positions and innovative technologies to deliver substantial free cash flow and sustainable shareholder value. The business is global in scope, with operations in 33 countries, and human in scale, with approximately 20,000 employees and long-standing, local relationships with its customers and communities. Based in Toledo, Ohio, U.S., Owens Corning posted 2021 net sales of $8.5 billion. It has been a Fortune 500 ® company for 67 consecutive years. Owens Corning is a publicly traded company on the New York Stock Exchange. As of December 31, 2021, beneficial ownership includes: Blackrock, Inc. (11.5%) and The Vanguard Group (9.73%). Read more about our businesses in the Owens Corning Annual Report on Form 10-K, available at http://investor.owenscorning.com . Owens Corning has manufacturing and research and development facilities around the world. Our world headquarters are located at One Owens Corning Parkway, Toledo, Ohio, 43659, U.S. Chin a In dia Sing ap ore So uth Ko rea Czech Re public Finland France It aly Li thua nia Be lgi um Po land Ru ssia Sp ain Swe den Un ited Kingdom Brazil Ca nada Mexico Un ited States Ne therla nds Germ an y

2021 Owens Corning Sustainability Report | Overview | About Owens Corning | 9 Best Corporate Citizens List For an unprecedented third year in a row, Owens Corning was ranked number one on 3BL Media’s list of the 100 Best Corporate Citizens. The list, previously published by Corporate Responsibility Magazine, recognizes outstanding global ESG (environmental, social, and governance) performance among the 1,000 largest U.S.- based public companies. This is the seventh year Owens Corning has been named to the list. The companies are ranked based on a blend of performance and disclosure. CDP Owens Corning earned a place on the CDP A List for Water Security for the third year in a row. The company also scored an A- for CDP Climate Change in 2021, which represents the sixth consecutive year of earning a score at the Leadership Level. Formerly known as Carbon Disclosure Project, the U.K.-based CDP works with investors, companies, and policymakers to reduce GHG emissions and safeguard water resources and forests. By including Owens Corning on these lists, CDP recognizes us for our corporate sustainability leadership, through scoring that “measures comprehensiveness of disclosure, awareness, and management of environmental risks, and best practices associated with environmental leadership, such as setting ambitious and meaningful targets.” Responsible CEO of the Year from 3BL Media CEO Brian Chambers was named 2021 Responsible CEO of the Year for ESG Transparency. The award recognizes chief executives with proven records of bold and innovative leadership on environmental, social and governance (ESG) commitments. Computerworld’s 2021 Best Places to Work in IT In 2021, Owens Corning returned to the No. 1 spot on Computerworld’s ranking of the best places to work in information technology. The ranking is based on such factors as benefits, diversity, career development, training, retention, and the results of an employee survey. This is the eighth consecutive year that Owens Corning has appeared on this list. In 2020, Owens Corning ranked No. 2 on the list, and was No. 1 in 2019. Corporate Equality Index Owens Corning received a perfect score on the 2021 Corporate Equality Index, a key benchmarking survey that evaluates corporate policies and practices related to LGBTQ workplace equality. This marks the 17th consecutive year we have received 100% on this survey, established by the Human Rights Campaign Foundation. DiversityInc 2021 Companies for Diversity Owens Corning was named a 2021 Noteworthy Company by DiversityInc, an organization that annually ranks U.S. companies for diversity, equity, and inclusion, for the second consecutive year. The rankings measure performance based on six key areas of diversity and inclusion management: human capital diversity metrics, leadership accountability, talent programs, workplace practices, supplier diversity, and philanthropy. Dow Jones Sustainability Indices In 2021, for the 12th year in a row, Owens Corning earned placement in the Dow Jones Sustainability World Index in recognition of its sustainability initiatives. The DJSI World Index is an elite listing of the world’s largest companies based on long-term economic, environmental, and social criteria. Our score places us in the 100th percentile for the building products industry. In addition, we earned a perfect score for the criteria related to materiality, environmental reporting, and social reporting. The company is also on the DJSI North America list for the 4th consecutive year. EcoVadis Owens Corning earned a Platinum certificate with EcoVadis, a company that provides holistic sustainability ratings for businesses worldwide. The rating comes after analyzing our responses to an extensive questionnaire in comparison with over 65,000 other companies. Owens Corning was ranked among the top 1% of all companies rated by EcoVadis. CORPORATE AWARDS AND DISTINCTIONS Owens Corning continues to be a leader in corporate responsibility, and we are very proud of the recognition we receive along the way. It also provides inspiration for our people as we seek out new ways to build a more sustainable company. The following are some of the awards and distinctions we received throughout 2021. A LIST 2021 WA TER

2021 Owens Corning Sustainability Report | Overview | About Owens Corning | 10 ENERGY STAR Owens Corning’s world headquarters in Toledo, Ohio, U.S., earned the Environmental Protection Agency’s ENERGY STAR rating for 2021. Ethisphere Institute: World’s Most Ethical Companies For the fourth consecutive year, the Ethisphere Institute, a global leader in defining and advancing the standards of ethical business practices, has recognized Owens Corning as one of the world’s most ethical companies. Owens Corning is one of two businesses in the construction and building materials industry to earn this distinction. The Ethisphere Institute honors companies that demonstrate a commitment to improving communities, building capable and empowered workforces, and fostering corporate cultures that are focused on ethics and a strong sense of purpose. In 2021, the Ethisphere Institute honored 135 companies from 22 countries and 47 industries. Fortune 500 ® As of 2021, Owens Corning has been recognized as a Fortune 500 ® company for 67 consecutive years. This year, Owens Corning moved up 18 places on the list to No. 413. Global Knights 100 Most Sustainable Corporations In 2021, Owens Corning earned the top spot for the Building Materials Industry Group, and we were ranked 15th overall. The ranking is based on publicly disclosed data spanning 24 key performance indicators for corporate ESG results. Based on the same data, the company also earned a place on the 2021 Clean200 list (published by Corporate Knights in partnership with As You Sow), which recognizes the world’s most significant publicly traded firms according to the size of clean revenue from products and services that provide solutions for the planet and define the future of clean energy. S&P Global Gold Class Distinction Owens Corning earned Gold Class distinction from S&P Global, the organization’s highest honor for excellence in sustainability performance, for the eighth consecutive year. Owens Corning was the sole Gold Class awardee in the Building Products category. S&P Global is a leading provider of credit ratings, benchmarks and analytics in the global capital and commodity markets. The S&P Sustainability Yearbook looks at performance across such factors as volunteerism, energy and emissions reduction, production efficiency, customer and supplier collaboration, and talent development. Green Power Partnership – National Top 100 In 2021, Owens Corning debuted at No.16 on the U.S. Environmental Protection Agency’s (EPA’s) National Top 100 List of the largest green power users from the Green Power Partnership. The company was also No. 11 on the list of Green Power Partners from the Fortune 500 ® . ISS QualityScore Institutional Shareholder Services (ISS) awards QualityScore ratings based on a range of criteria related to environmental, social, and governance performance. A lower score, on a scale from one to ten, indicates lower risk and/or better disclosure on the part of the company. In 2021, Owens Corning’s ISS QualityScore ratings were 1 in environmental, 1 in social, and 2 in governance. JUST Capital Owens Corning was ranked Industry Leader for Building Materials and Packaging for 2021. We were also No. 69 in the Just 100. Companies are rated based on their performance across a range of categories, including the treatment of employees and customers, product quality, sustainability, jobs, and community support, as well as company leadership. Science Based Targets Initiative Our 2030 goal to reduce Scope 1 and 2 greenhouse gas emissions by 50% is in line with standards set to hold global warming to 1.5° Celsius. The Science Based Targets initiative, which set these standards, has approved our goal. In addition, Owens Corning’s commitment to reducing Scope 3 greenhouse gas emissions by 30% by 2030 has been approved by the Science Based Targets initiative. WSJ Management Top 250 Owens Corning ranked No. 54 in 2021, up from No. 99 in 2020 and No. 188 in 2019. This ranking, developed by the Drucker Institute, measures corporate effectiveness by examining performance in five areas: customer satisfaction, employee engagement and development, innovation, social responsibility, and financial strength. The ranking is based on an analysis of 34 data inputs provided by 14 third-party sources.

2021 Owens Corning Sustainability Report | Overview | The Fight Against Climate Change | 11 Having been part of Owens Corning’s sustainability journey for over 20 years, I have seen firsthand the incredible progress that we, and other dedicated companies, have made toward building a better future. While we, as corporations and as a society, have made great gains in reducing our environmental impact, our collective actions are not achieving the magnitude, scale, and urgency needed. Severe weather phenomena, from droughts and wildfires to storms and floods, are occurring with greater frequency and greater severity than ever before. Global climate change, linked to human behavior, is now a scientifically recognized driver of these localized weather events. To help stem the devastation that is occurring as a result, the International Panel on Climate Change (IPCC) has issued recommendations aimed at limiting warming to 1.5° C. Their latest reports have made clear the need to act decisively: The planet’s air, oceans, and ice are pushing relentlessly into new territory. Unless there are immediate, rapid, and large-scale reductions in greenhouse gas emissions, limiting warming to 1.5° C will be beyond reach. Consistent with this call to action, Owens Corning is committed to a decarbonized future. Our 2030 goal for reducing Scope 1 and 2 greenhouse gas emissions by 50% has been approved by the Science- Based Targets initiative (SBTi) as being in alignment with the IPCC’s 1.5° C maximum global warming pathway. Concurrently, our Scope 3 greenhouse gas reduction goal of 30% has been approved by the SBTi as being in alignment with the IPCC’s well below 2.0° C pathway. Our definition of total value chain decarbonization is also consistent with the new SBTi guidance. More information about our work on this front can be found in the Combating Climate Change chapter in this report. OWENS CORNING AND THE FIGHT AGAINST CLIMATE CHANGE THOUGHTS FROM CSO FRANK O’BRIEN-BERNINI

2021 Owens Corning Sustainability Report | Overview | The Fight Against Climate Change | 12 The importance of embracing these standards has never been more urgent. While certainly the talk of climate scientists for years, the IPCC process was the first time the scientific community has established a clear connection between these localized weather events and human- driven climate change. The higher temperatures associated with climate change have intensified the water cycle, leading to warmer oceans, heavier rainfalls, and increased flooding, as well as higher sea levels along coastal areas. In addition, hotter climates are linked to droughts and fires in other parts of the world. As more studies link catastrophic weather events to the emission of greenhouse gases, they serve to confirm what many people have long understood: While weather and climate are in many ways two separate concepts, they are clearly tied together, and changes in the climate have very real consequences in our everyday lives. It has also underscored the need for everyone — corporations and individuals alike — to take action to limit our impact on our global climate. Scientists often seek to maintain optimism about the extent to which mitigating climate change is possible. However, there is good reason to believe that we are destined to live in a world that has been significantly touched by climate change, with higher temperatures and more extreme weather conditions. Because we will be affected by the impact of these changes for countless generations to come, we must elevate our focus on adaptation and carbon removal, even as we continue to work diligently to mitigate our greenhouse gas emissions. Our commitment to decarbonization is evident throughout this report, as is our dedication to the new materials and material system opportunities available to us as we work to both mitigate and adapt to the impacts of climate change. This report is full of incredible photos spotlighting the beauty of the natural world. As readers browse the report, we hope they will recognize how fragile these landscapes are, and the potential damage that even small increases in temperature might have on them. Images like these serve as an acute reminder of exactly what is at stake as we work to build a more sustainable future. Photo submitted by: Tim Clancy | Toledo, Ohio, U.S. View from a cabin in Northern Michigan.

2021 Owens Corning Sustainability Report | Overview | Our Sustainability Aspirations | 13 OUR SUSTAINABILITY ASPIRATIONS Owens Corning has established itself as a global leader in corporate citizenship, and over the years our efforts have been rewarded with some very prestigious accolades. While that recognition has been gratifying, the true driver behind our sustainability efforts has been an understanding that our planet simply cannot continue to sustain life (as we know it) if we remain on the path we are on. Resources are diminishing, temperatures are rising, and people everywhere are feeling the impact. All of this is reflected in the sustainability aspirations we have set for ourselves as a company. They are ambitious by design, because we believe true sustainability is based not on what is easy for us to accomplish, but on what the science tells us is needed to preserve our planet. In addition, our sustainability journey has consistently reminded us that as we achieve more, we realize how much more can be done. Every accomplishment points us toward new opportunities to fulfill our ultimate ambition — ensuring that our people and our products make the world a better place. Photo submitted by: Yana Liu | Shanghai, China Sun-drying Chinese torreya, a special local product, near our Guangde plant. 2030 GUIDING ASPIRATIONS Have a POSITIVE IMPACT on our communities ADVANCE our inclusion and diversity Eliminate injuries and IMPROVE THE QUALITY OF LIFE for our employees and their families HALVE THE NEGATIVE IMPACT of our operations These are the principles that will inform our actions as we work toward our goals. They represent our understanding of the ways Owens Corning’s work can benefit individuals, communities, and the planet — and how valuing one requires that we value all three. By 2030, we expect the world will be a very different place. Increasing demands on the earth’s resources will continue to create challenges. By taking the stance we are taking today — leading the way with an ambitious, holistic approach to sustainability — Owens Corning believes we can help make the world of 2030 a better place. DOUBLE the positive impact of our products

2021 Owens Corning Sustainability Report | Overview | Our Sustainability Aspirations | 14 Data-Driven Solutions for Sustainability Each step on our sustainability journey is measured against a set of quantifiable metrics and specific targets. As our journey has progressed, we have worked to develop data-driven methods that provide quantifiable measures of our improvement. The following examples demonstrate this commitment across all three of our key pillars: Expanding Our Product Handprint: ■ Life Cycle Assessments (LCAs) enable us to comprehensively measure a product’s footprint through all its stages, from the extraction of raw materials, through transportation, processing and manufacturing, to its end of life disposition. By performing LCAs, we can identify opportunities for improvement and work collaboratively with suppliers and customers to ensure we are making continuous progress toward doubling the positive impact of our products. Reducing Our Environmental Footprint: ■ In our 2030 goals, we seek to reduce our greenhouse gas emissions from our operations by half, in line with what’s needed to limit global warming to 1.5° C. Our target has been validated and approved by the Science Based Targets initiative. ■ To understand how water stress is affecting an area, we refer to the Aqueduct Water Risk Atlas, a resource developed by the World Resources Institute (WRI). With this global water risk mapping tool, we screen our sites for high baseline water supply stress and see projections for the levels of stress these sites may be under in years to come. Understanding the areas where water is limited in quantity or quality is essential to our water goals, and this tool provides us with the insights needed to achieve them. ■ As we work toward the establishment of our biodiversity goals, we use the Integrated Biodiversity Assessment Tool (IBAT), a web-based mapping and reporting instrument. IBAT enables us to upload site coordinates and receive information about the area’s status as a protected site and the presence of endangered or threatened species in the vicinity. When our goals are established in 2025, the IBAT will continue to guide our biodiversity efforts. ■ The Ecodesign Strategy Wheel is a brainstorming tool that empowers product designers to integrate the principles of sustainability into the development of new products and the significant modification of existing products. More sustainable product design can help us contribute to the circular economy, as well as meet the goals we have set for both waste management and air quality management. Increasing Our Social Handprint: ■ Our health and wellness initiatives are increasingly guided by our use of the Healthy Living platform, which employs an algorithm that considers illnesses, medication usage, demographics, and other factors to calculate health risks for our employees and empowers them to make better choices. ■ Historical data, current data, and key performance indicators provide our safety teams with the insights needed to track performance, identify trends, and tap into real-time metrics. We also continue to use safety dashboards and databases to further our efforts in that area. Learn more about Owens Corning’s sustainability goals and targets in the Summary & Highlights of this report. A Holistic Approach to Sustainability We believe that sustainability efforts should improve people’s quality of life. That view informs our aspirations to contribute to the health, safety, and well-being of people — and all living things — everywhere. It’s our goal to be a net-positive company, one whose handprint is greater than our footprint. In other words, we aim to continually increase the good that our people and products do while also reducing the negative environmental impact of our operations. These aspirations are closely connected. For example, when we design insulation products that help save energy, that’s part of our handprint, as those products help our customers and end-users meet their sustainability goals. When we design those same products with higher recycled content, or to be easy to recycle or repurpose as part of the circular economy, that expands our handprint further. And when we design our manufacturing processes to use less energy or other natural resources, we reduce our footprint. Over time, our definition of sustainability has also come to include expanding our social handprint, and so we work to help ensure that people can live with health, happiness, and human dignity. Our safety commitments are one pillar of this, as we aspire to eliminate all injuries, at work and at home. Our health and wellness programs aim to help our employees and their families thrive while eliminating all lifestyle-induced disease. In our workplaces and our communities, we seek to foster a spirit of inclusion and create a culture of appreciation. We want to see a society where people feel valued not despite their differences, but because of them. Above all, we understand that achieving these ambitions will depend on the actions we take today.

2021 Owens Corning Sustainability Report | Overview | Our Sustainability Aspirations | 15 Top Areas of Focus The work we’re doing toward our 2030 sustainability goals is described in more detail in the chapters of this report. There are several key areas of work that will support the goals. In some cases, multiple goals will be affected by one focus area. Accountability for progress on these critical priorities rests with our top business executives, ensuring broad engagement across the company in our sustainability work. These 11 areas represent a wide range of projects, initiatives, and opportunities for Owens Corning — our progress toward these priorities is chronicled in this report. Blowing agent. Solve the technical, business, and commercial puzzles in both our global foam insulation operations and our products to eliminate blowing agents that have high global warming potential. Renewable energy sourcing. Further reduce demand through energy efficiency and concurrently expand our renewable energy investments and purchases globally, establishing programs in China, India, Mexico, Brazil, Europe, and Canada to reduce the footprint of both our operations and our products. Fuel switching. Develop affordable technology to enable conversion from fossil fuel to carbon-neutral and renewable energy to power our processes. Expand our offering of formaldehyde-free insulation products . Convert to formaldehyde-free binders for global production of our technical insulation and mineral wool products. Embodied carbon. Reduce the amount of carbon released throughout the entire life cycle of our products by making our manufacturing processes more energy-efficient, improving our supply chain logistics, increasing recycled content, innovating low/ no/positive carbon products, and developing end-of-life solutions. Recycling into our processes. Increase the amount of recycled materials and production waste we use in our products and processes, tapping into waste- streams throughout our entire value chain, while eliminating waste-to-landfill. Safety. Advance in our journey to zero injuries by understanding, learning, innovating, and executing the right safety-related leadership, processes, and investments. Circular economy. Develop business models and technical solutions to recycle Owens Corning ® roofing, composites, and insulation products to advance the circular economy, reduce waste-to-landfill, and enable us to take back scrap material from our customers’ processes. Healthy living innovation. Develop strategies and tactics to inspire and engage all U.S. employees who are not yet enrolled in our wellness initiatives, and expand the participation of our employees outside the U.S. Inclusion and diversity. Identify and close gaps, measure progress, enable success with business impact, and evolve our leadership voice, while fostering a culture where our individual differences are truly appreciated. Supplier sustainability. Inspire our suppliers to engage with us around sustainability priorities while increasing transparency, such as reducing our Scope 3 greenhouse gas emissions and ensuring certainty of compliance with our human rights policy.

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 16 2021 IN REVIEW SUMMARY & HIGHLIGHTS Owens Corning is making great progress toward our 2030 goals — and toward our mission of building a more sustainable future. Photo submitted by: Scott Campen | Knoxville, Tennessee, U.S. Coconino National Forest, Arizona, U.S. INTRODUCTION Having closed the books on our 2020 sustainability goals, we are now looking ahead to the next decade with great optimism. Our slate of 2030 sustainability goals are our most ambitious to date, because we recognize that every past achievement is a platform upon which to build. In 2021, we saw encouraging advancements across all three of our sustainability pillars, giving us reason to believe that we are on the right track toward our aspirations. Each of the topics discussed here has a corresponding chapter in this report, offering a closer look at our progress against our goals, as well as the drivers that inform our approach, the initiatives we’re taking throughout our operations, and the progress we’ve already made. The following is a brief look at some recent highlights.

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 17 Our Circular Economy Goal By 2030, we will establish viable circular economy business models involving our materials and how they are used. We can accomplish this by: ■ Increasing recycled content and decreasing virgin raw materials used in our products. ■ Developing technical solutions and practical business models for our product materials and packaging, so they can be used for beneficial purposes even after they are no longer used for the original purpose. ■ Collaborating up and down the supply chain, with customers, suppliers, communities, academics, policy makers, government entities, and other organizations. Our circular economy efforts are focused in two areas: ■ Manufacturing This work focuses on meeting our 2030 waste management goals — reducing the intensity of waste generated by our processes by 50%, and then finding ways to reuse or recycle the rest — as well as our efforts to expand the use of recycled materials in our manufacturing operations and our products, across all businesses. ■ End-of-life solutions We are seeking innovative technologies and business models for our products and materials to be reused and repurposed indefinitely. This work includes internal partnerships among R&D, commercial, and corporate development to shape the vision and execution in this area. We also engage with external partners to develop end-of-life solutions for our products, as well as the products where our materials are used. EXPANDING OUR PRODUCT HANDPRINT Owens Corning works to ensure our products have a positive impact on the world. We believe that by innovating in ways that benefit the planet, we can also help our customers — and strengthen our own business. It’s a principle that requires us to act intentionally, and it informs everything we do as a company. Our most recent initiatives toward establishing circular economy models include the following: ■ The circular economy team , established in 2020, defines goals and prioritizes projects that accelerate our circular economy ambitions. The team also partners with subject matter experts and teams across our company, as well as other stakeholders in the industry. ■ Take-back models encourage manufacturers to accept responsibility for downstream waste from customers using their products. For Owens Corning, this can include waste generated during construction, subsequent fabrication, installation, or protective packaging. Owens Corning Paroc has established take-back models in Sweden and Finland, as well as in our metals packaging products. ■ Shingle recycling efforts are in place, as our Specialty Asphalt paving business is working with state departments of transportation, roofing contractors, and other stakeholders to create a circular economy model for roofing shingles. ■ Owens Corning is a partner in the ZEBRA (Zero WastE Blade ReseArch) project in Europe, a cross-sector consortium launched in 2020 to develop the first 100% recyclable wind turbine blade. Photo submitted by: Houston Plant | Houston, Texas, U.S. Rodney Ivy (left) and Margarito Barreto at the Houston plant.

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 18 Photos: PINK Next Gen™ Fiberglas™ (left) WindStrand ® (center) Trumbull ® Asphalt (right) Product Innovation & Stewardship By 2030, we intend to offer the most recognized and preferred products for sustainability. ■ To meet this ambitious goal, we are striving to implement strategies that deliver the lowest impact with respect to embodied carbon among all available options. ■ We will design our products for recycling or reuse at their end of life while using Life Cycle Assessments as our guide. We will ensure our products contain a high percentage of recycled and renewable materials. In addition, we will collaborate with our suppliers to increase transparency regarding the raw materials we use in our products. This helps us understand and control the full impact of our products — and enables us to share that information with our customers so they can do the same. ■ Product innovation is essential to all three of our core businesses — Composites, Insulation, and Roofing — as we develop new products and applications across a growing range of key market segments. This innovation is inspired by the needs of our customers and addresses growing global trends. By collaborating closely with stakeholders, we can deliver sustainable solutions that meet the demands of the marketplace. ■ Product stewardship is a driving force behind our approach to innovation. As we develop new products or improve existing products, everyone involved understands that they share the responsibility for reducing those products’ environmental footprint and increasing its product handprint. At every point in a product’s life cycle, we must consider its potential environmental impact — and demonstrate transparency regarding the sustainability of our products. To mitigate that impact, we work to ensure our products are sustainably made, using our stringent stewardship process to evaluate 100% of our new and significantly modified products for EHS impacts and our gated innovation process to evaluate potential life cycle impacts. Recent innovations in our portfolio include the following: ■ PINK Next Gen™ Fiberglas™ insulation , launched in 2021, offers the highest recycled content in the industry, and it is certified made with 100% renewable electricity through the use of power purchase agreements. In addition, it has earned Underwriter Laboratories GREENGUARD ® Gold certification for low volatile organic compounds. ■ PAROC ® Natura insulation is a carbon-neutral line of stone wool insulation that uses low-carbon melting technology, green electricity, recycled waste materials, new technologies, and purchased carbon offsets to minimize the amount of CO 2 e emitted during the manufacturing process. ■ FOAMULAR ® NGX™ insulation, introduced in 2020, features a proprietary blowing agent that is optimized to demonstrate greater than 80% reduction in embodied carbon, compared to legacy FOAMULAR ® insulation products. The product meets and exceeds stringent regulations going into effect in 2021. ■ WindStrand ® allows wind blade manufacturers to use 30% fewer layers of material in the blade molds, while delivering the same quality and performance as standard fabrics. This in turn represents a 50% savings in labor and production time for the blades. In March 2021, we introduced WindStrand ® 4000, as well as Ultrablade ® 2 and Ultraspar™ 2, three high-performance materials that help wind blade manufacturers develop longer, stiffer, stronger blades, which helps make wind energy more cost-effective. ■ Trumbull ® Asphalt has made significant strides over the last five years to reduce the number of oxidized products we produce for external asphalt markets. In 2015, 8% of our products were non-oxidized. Today, approximately 50% of the products we produce for the external asphalt business are non-oxidized, requiring less energy, lower temperatures, and fewer emissions. This has resulted in a 3% improvement in material efficiency across the 12 asphalt plants in the network.

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 19 Sustainable Growth By 2030, we will design our products for recycling or reuse to optimize the impact of our products over their entire life cycle, from raw materials to disposal. Over the next nine years, Owens Corning expects that the importance of balancing growth with sustainability will become increasingly evident. We will be there to meet the demand for products that deliver performance while minimizing negative impacts. In particular, we recognize the growing demand for reduced embodied carbon, which is already shaping our approach to innovation throughout our operations. Among the other specific areas of focus Owens Corning has prioritized for the immediate future is the need to expand the number of products that are free of formaldehyde and fluorocarbons. One way Owens Corning gauges our performance toward our sustainable growth goals is the extent to which we are addressing the trends that are shaping our industry. As we look to the future, we are also cognizant of these trends as significant opportunities to grow while at the same time meeting our 2030 sustainability goals. Currently, we see four primary trends that represent opportunities for sustainable growth over the next decade. ■ Increased premium on living spaces. The global pandemic has changed how we think about our homes, both in terms of functionality and comfort. This new emphasis on living spaces will continue to drive investments in new residential housing and renovation in the U.S. and abroad. Insulation is one of the best ways to improve energy efficiency and indoor comfort, including sound reduction. ■ Changing construction practices. Even before the pandemic, we saw how labor shortages were impacting construction practices and cycles. Since early 2020, the trend has accelerated, creating the need for multi-material and prefabricated construction solutions that can drive efficiencies. Owens Corning PINK Next Gen™ Fiberglas™ enables 23% faster installation. Fiberglas™ rebar, which is seven times lighter than steel, improves ease of handling for 50% faster installation. ■ Demand for sustainable solutions. Reduction of greenhouse gases, improvements in energy efficiency, and the development of more renewable energy sources are increasingly prioritized by homeowners. Governments at all levels are also requiring increasingly stringent standards. Both factors are driving specifications throughout the industry. For example, the European Green Deal Commission proposed that by 2030, all new buildings in the European Union be zero-emission, and Owens Corning products could be part of meeting that goal. ■ Investment in infrastructure. We expect to see upgrades to roads and bridges to continue around the world over the next decade. We also expect that this investment will prioritize more durable solutions, which will help ensure that investments will be more sustainable over time. We will capitalize on these opportunities by focusing on our unique combination of material science knowledge, commercial strength, and manufacturing expertise to develop and commercialize additional product and system solutions. Photo submitted by: Michele Mazza | Trophy Club, Texas, U.S. Little Rock, Arkansas, U.S.

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 20 Supply Chain Sustainability By 2030, 100% of our suppliers will meet our Supplier Code of Conduct requirements, with special attention to human rights issues such as safety and forced labor. We will continue to prioritize supply chain partners that share our commitment to sustainability in all its forms. In line with the Supplier Code of Conduct, in 2021, 100% of new suppliers were evaluated for a range of criteria, including environmental and social factors (e.g., human rights and labor practices). In 2021, Owens Corning enhanced our approach to prioritizing suppliers, empowering us to further emphasize the importance of sustainability throughout our value chain. This approach provides additional consideration of our suppliers’ environmental, social, and governance (ESG) risk exposures. The environmental, social, and governance risk scoring framework is based on S&P Global Rating’s ESG Risk Atlas. A sector risk score, which encompasses associated environmental and social risk rationales, is assigned based on the supplier’s commodity. A regional risk score, which embodies governance rationales, is assigned to a supplier’s country. The overall ESG Risk Score is then tallied for each supplier by adding the 3 E, S, and G risk scores. For suppliers who provide multiple commodities to Owens Corning, and therefore potentially have multiple ESG risk scores, we selected the highest ESG risk score to conservatively represent these suppliers. Photo submitted by: Felicia Feng | Yantai, China FOAMGLAS ® insulation ready to be shipped. 100% of team trained or recertified. 2021 2020 2019 100% 100% 2018 100% Supplier Code of Conduct Compliance GOAL: 100% 98% 2021 95% 2019 96% 2020 201 8 BASE YEAR 95% In addition, 100% of our global sourcing team will be trained and recertified annually on sustainability. A standardized process has been implemented across global sourcing and will be used in category strategies going forward.

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 21 Energy Efficiency & Sourcing Renewable Energy By 2030, we will be sourcing 100% renewable electricity. Purchasing electricity only from renewable sources is a key part of our effort to halve our greenhouse gas emissions. We’ll also work to reduce the emissions from our processes and improve energy efficiency. We will also reduce energy use by 20% over our baseline year. Over our goal cycle, we will work to reduce energy use from both renewable and non-renewable electricity, as well as other forms of non-renewable energy by 20% from our baseline year of 2018. These two approaches — along with fuel switching and low-carbon or no-carbon fuels and technologies — will put us on the path to eventually eliminating our use of fossil fuels. REDUCING OUR ENVIRONMENTAL FOOTPRINT Throughout our operations, Owens Corning is working to conserve energy, reduce emissions, cut waste, and use water responsibly. Through these efforts — which will require a great deal of dedication and collaboration among our employees — Owens Corning is actively working to mitigate our negative impact around the world. Photo submitted by: Caio Tralba | São Paulo, Brazil Toque Grande beach, São Paulo. 2030 Renewable Electricity GOAL: 100% R ENEWABLE 51% 2021 201 8 BASE YEAR 48% 50% 2019 52% 2020 2030 Energy Efficiency (MWh) GOAL: 20% REDUCTION 2% 10,499,961 2021 201 8 BASE YEAR 10,719,236 4% 10,274,193 2019 10% 9,658,731 2020

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 22 Combating Climate Change By 2030, our goal is a 50% reduction in absolute Scope 1 and Scope 2 market-based greenhouse gas from the base year of 2018. ■ Scope 1 refers to the direct emissions from our own manufacturing operations. ■ Scope 2 refers to indirect emissions from the generation of purchased energy. We also have a goal to reduce absolute Scope 3 emissions by 30%. ■ Scope 3 refers to other indirect emissions, primarily those from our supply chain. Photo submitted by: Michele Mazza | Trophy Club, Texas, U.S. Monarch butterfly. Absolute Scope 1 and Scope 2 (Market-Based) Greenhouse Gas Emissions (metric tons of CO 2 e) GOAL: 50% R EDUCTION 12% 3,426,681 2021 201 8 BASE YEAR 3,882,168 5% 3,674,834 2019 14% 3,352,168 2020 Absolute Scope 3 Greenhouse Gas Emissions (metric tons of CO2e) GOAL: 30% R EDUCTION 8% 3,345,559 2021 7% 3,388,860 2020 0% 3,630,73 1 2019 201 8 BASE YEAR 3,624,857

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 23 Air Quality Management By 2030, we will reduce the aggregate intensity of our emissions of volatile organic compounds (VOCs) and fine particulate matter (PM2.5) by 50%. We also manage, track, and report against NOx and SOx air emissions requirements. The ways we measure and control NOx and SOx vary by location and local regulatory requirements. Photo submitted by: Julie Childers | Granville, Ohio, U.S. Key West, Florida, U.S. VOC Emissions Intensity (metric tons normalized by revenue, in millions) GOAL: 50% R EDUCTION 18% 0.273 2021 201 8 BASE YEAR 0.331 5% 0.313 2019 10% 0.299 2020 PM 2.5 Emissions Intensity (metric tons normalized by revenue, in millions) GOAL: 50% R EDUCTION 14% 0.280 2021 201 8 BASE YEAR 0.326 6% 0.306 2019 11% 0.290 2020

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 24 Responsible Water Sourcing & Consumption By 2030, we will cut in half the amount we take from local water supplies in places where water is limited in quantity or quality. In addition, we intend to ensure that our other facilities remain at the same water intensity as our base of 2018, or lower when aggregated. Photo submitted by: Priyanka Ruparel | Mumbai, India Cityscape in India. High Water-Stress Sites Water Withdrawal Intensity (cubic meters normalized by revenue, in millions) GOAL: 50% R EDUCTION 20% 2,351 2021 All Other Sites Water Withdrawal Intensity (cubic meters normalized by revenue, in millions) GOAL: REMAIN FLAT OR REDUCE 201 8 BASE YEAR 2,94 0 1% 2,90 4 2019 10% 2,63 7 2020

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 25 Waste Management By 2030, we will send zero waste to landfill, using the following two-part plan: ■ Reduce waste intensity by 50% by improving efficiency and process design. ■ Repurpose or recycle the remaining waste, including recycling waste back into our own processes whenever possible. FPO FPO Photo submitted by: Susan Raneri | Massachusetts, U.S. Golf course, Northborough, Massachusetts. Intensity of Waste/Byproducts Generated (metric tons normalized by revenue, in millions) GOAL: 50% R EDUCTION 201 8 BASE YEAR 13 0 7% 12 1 2019 10% 117 2020 17% 108 2021 62% 2021 201 8 BASE YEAR 60 % 64% 2020 63% 2019 Percentage of Remaining Waste/Byproducts Repurposed or Recycled GOAL: 100% REPURPOSED OR RECYCLED

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 26 Photo submitted by: Karen Bonner | Toledo, Ohio, U.S. Great Smoky Mountains National Park, Tennessee, U.S. Protecting Biodiversity Our 2030 goals for biodiversity will be based on the work we are currently doing to understand the full impact of our operations. We will have established our specific goals based on our findings by 2025. Achieving our biodiversity goals will require a broad- based network of collaborators, both internal and external, including our partnership with the Science Based Target Network, which provides us with a rigorous framework upon which we will build our biodiversity goals. This deep level of cooperation across all levels will be increasingly necessary as we seek to protect the closely interrelated web of species with which we share the planet. Owens Corning uses the Integrated Biodiversity Assessment Tool (IBAT) to gauge our proximity to areas with high biodiversity value. By employing a science-based, data-driven approach, we can make decisions that have the most positive impact for the species we are working to preserve.

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 27 Employee Experience By 2030, in conjunction with our inclusion and diversity goals, we will make continuous improvements in recruiting, retention, training and development, mentorship and sponsorship professional growth, and employee engagement. To that end, we have established a number of specific targets: ■ 100% retention of high-potential talent between annual talent reviews. ■ Internal fill rate of 75%-85% for leadership roles. ■ Ensure two “ready now” internal succession candidates for key leadership roles. ■ >95% of staff indicating they are frequently putting all their effort into their work. ■ 90% staff and 85% primary worker response rate to our two global enterprise surveys. EXPANDING OUR SOCIAL HANDPRINT Creating a better world means ensuring a better quality of life for people everywhere — from our employees and their families to people in the communities where we do business. We seek to help our employees thrive during their tenure with us, and for people everywhere live with health, safety, and human dignity. 2030 Retention Target 100% retention of high-potential talent between annual talent reviews. We want to ensure that our top talent remains proud members of the Owens Corning team. According to the Society for Human Resource Managers (SHRM), this is the top quartile for outstanding companies, which makes it a suitable goal for Owens Corning. 2030 Employee Engagement Targets >95% of staff indicating they are frequently putting all their effort into their work. We measure engagement by combining the percentage of people who respond Agree or Strongly Agree on our annual employee engagement survey. This is a common practice among the engagement surveys against which we set our benchmarks. Our figures place us high above the SHRM average of 69% who respond similarly. 90% staff and 85% primary workers response rate to our two global enterprise surveys. Owens Corning measures employee engagement in a variety of ways. For example, every other year, our staff is asked to complete a Leadership Capabilities for Growth survey, and our primary population is asked to complete an Operation Excellence survey. Our survey response rate is already well above the 30-40% average response rates for internal employee surveys, and our goal is increase it even further as we work toward 2030. 2030 Percentage of High-Potential Talent Retained GOAL: 100% 2018 2019 2020 2021 Employee Engagement (% of actively engaged employees) 97% 97% 98% 98% % of total salaried employees responding 89% 89% 89% 89% 96% 2021 201 8 BASE YEA R 96 % 98% 2019 97% 2020 0 20 40 60 80 100 2018 (Base Year ) 2019 2020 2021 2030 Goal Percentage of Prima ry W orkers Percentage of Staf f 2030 Staff Goal 90% Response 2030 Primary Goal 85% Response 89% 80% 89% 80% 89% 80% 89% 70%

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 28 2030 Succession Targets Internal fill rate of 75%-85% for leadership roles. We aspire to have mid-level, director, and vice president-level roles filled by current Owens Corning employees, either through a promotion or as a lateral move, as a percentage of all internal fills and external hires for these roles. As we build our diverse talent pipeline, promoting from within strengthens our inclusive environment as employees see diversity among our leaders. Ensure two “ready now” internal succession candidates for key leadership roles. We calculate this by taking the number of unique candidates who are ready for promotion into the key leadership role divided by the number of succession roles in that business unit. Although strong candidates may be on multiple succession lists, each individual is counted only once within that business unit. In addition, we have set succession targets to help increase representation from women and people of color. Photo submitted by: Danielle Wittorp | Dearborn, Michigan, U.S. Sunflower and bee in a home garden. 2030 Goal 75-85 % within range 2019 84% Staff 2021 82% Staff 2018 BASE YEAR 73% Staff 2020 87% Staff 100% 0% Percentage of Leadership Roles Filled from Within 0.0 0.5 1.0 1.5 2.0 2.5 2018 (BASE YEAR) 2019 2020 2021 2030 Goal 2.0 2.22 .2 2.11 .8 Sucession Pipeline Readiness

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 29 People of Color in Leadership As part of our 2030 goals, we have set a target that 22% of our U.S. leadership roles are filled by people of color (POC). In 2021, our representation for these roles was 15%, while overall approximately 51% of U.S. hires were people of color. Inclusive Leadership Training We had set a target for 100% of our people leaders, from first level leaders through mid-level leaders, directors, and vice presidents to attend our internal inclusive leadership training by the end of 2021. While we fell short of that goal, we maintain a 2030 target to maintain training at that level for all new hires or promotions into those roles. Percentage of POC Leaders 2030 GOAL: 22% 15% 2021 2018 BASE YEAR 13% 14% 2019 14% 2020 Women in Leadership We have established a 2030 target in which 35% of our global mid-level leader, director, and vice president roles are filled by women. Percentage of Female Leaders 2030 GOAL: 35% 27% 2021 2018 BASE YEAR 24% 25% 2019 25% 2020 Percentage of Females in Successor Pool 2030 GOAL: >35% 30% 2021 2018 BASE YEAR 25% 26% 2019 28% 2020 Inclusion & Diversity By 2030, we aspire to: ■ Build and support diverse workforce and leadership teams that reflect the communities in which we live, work, and serve. ■ Retain diverse candidates proportional to the communities in which we live, work, and serve. ■ Increase internal succession with an emphasis on expanding the number of female candidates, underrepresented minorities, and representation of cultures from around the world. ■ Demonstrate transparency regarding pay equity through periodic third-party reviews and ongoing internal analytics. We have formalized our commitment to these goals by setting several specific targets that quantify our inclusion and diversity aspirations. Percentage of People of Color in Successor Pool 2030 GOAL: >22% 17% 2021 2018 BASE YEAR 16% 14% 2019 18% 2020

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 30 Photo submitted by: Kelly Picking | Toledo, Ohio, U.S. Inclusive Leadership Training We had set a target for 100% of our people leaders, from first level leaders through mid-level leaders, directors, and vice presidents to attend our internal inclusive leadership training by the end of 2021. While we fell short of that goal, we maintain a 2030 target to maintain training at that level for all new hires or promotions into those roles. Percentage of People Leaders Trained on Inclusive Leadership 2030 GOAL: 100% 82% 2021 2018 BASE YEAR 24% 2019 56% 2020

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 31 Community Engagement By 2030, 100% of our employees will be actively engaged in their communities through company- sponsored activities. As part of this goal, we continue to engage facilities in community projects. By 2022, we intend to see 100% facility engagement, which will serve as a foundation for our broader 2030 goal. Number of Volunteer Experiences* While COVID-19 restrictions led to a significant drop in volunteer experiences between 2019 and 2020, we are pleased to see our numbers trending upward in 2021. We are confident that volunteering will continue to increase as more communities begin to emerge from the pandemic. * While our ability to track and measure employee volunteerism improves every year, we are currently only able to track the number of volunteer experiences and not individual volunteers. The number of volunteer experiences serves as an informative reference as we expand our reach to all global facilities. Living Safely By 2030, we aspire to achieve the following goals: ■ Make it impossible for injuries and illnesses to occur. Ideally, we will do this by designing equipment and processes to eliminate risk. When an engineering solution isn’t possible, we will continue to evaluate and implement strong rules and policies and ensure use of appropriate protective equipment to keep people from hazards. ■ In new or newly acquired sites, achieve a level of safety at least equivalent to the rest of Owens Corning within one year. In 2021, Owens Corning acquired vliepa GmbH, a German-based company specializing in the coating, printing, and finishing of nonwovens, paper, and film for the building materials industry. We have been working to apply our safety processes to their operations as we complete the acquisition of this company. ■ Emphasize the elimination of risks that could lead to the most serious injuries, rather than concentrating on only the most frequent ones. We aspire to eliminate all employee, contractor, and visitor injuries and occupational illnesses at work and at home, beginning with the ones that have the most serious consequences. While Owens Corning has a long-standing commitment to safety, we recognize there is still work to do as we keep our eye on our 2030 goals. Our recordable incident rate (number of injuries x 200,000 / total labor hours) in 2021 was 0.59. This is 81% below the industry average, as reported by the U.S. Bureau of Labor Statistics for 2021 (the most recent data available). In addition, 48% of our global facilities were injury-free in 2021. The severity of our incidents, measured by our lost-time injury frequency rate (lost workday cases x 1,000,000/total labor hours) was 1.69.

2021 Owens Corning Sustainability Report | Overview | Summary & Highlights | 32 Health & Wellness By 2030, we aspire to eliminate all lifestyle-induced disease and enable the best possible quality of life — where people flourish and are healthier because they work for Owens Corning. Human Rights & Ethics By 2030, 100% of our suppliers will meet our Supplier Code of Conduct requirements, with special attention on human rights issues such as safety and forced labor. While complying with privacy laws and local expectations, we will use accessible data, as well as health and behavioral science, to define metrics that will guide our strategies and tactics to achieve our goals. We will be guided by the frameworks established by the U.S. Healthy People 2030 as well as the WHO Global Action Plan. Each framework is based on indicators that measure both health risks and the burden of disease around the world. Owens Corning recognizes that change is inevitable, and it’s happening faster than ever. As we look ahead to 2030, we recognize that we must be prepared to anticipate change — and innovate accordingly. We are confident that the goals we have set are within our reach, thanks to the collective spirit of dedication, collaboration, and ingenuity of our employees around the world. Photo submitted by: Jim Close | Toledo, Ohio, U.S. Wisconsin Dells, Wisconsin, U.S. Each year, we conduct a survey assessment of our key suppliers. In 2021, those suppliers constituted 74% of our sourcing managed spend. They are asked to report their own policies regarding a range of topics, including human rights and ethics. Of the suppliers who have responded to our survey assessments over the past three years, 98% reported that they meet the standards set by our Supplier Code of Conduct. 98% 2021 201 8 BASE YEAR 95% 2019 96% 2020 Supplier Code of Conduct Compliance GOAL: 100%

In this section, we discuss the various factors that influence how we think about sustainability — and the steps we will take to achieve our 2030 goals. ■ Stakeholder Engagement & Material Issues ■ UN Sustainable Development Goals Alignment ■ Board Leadership ■ Risk Management ■ Digital Transformation ■ Compliance and Beyond ■ Total Productive Maintenance ■ Ta x OUR APPROACH

2021 Owens Corning Sustainability Report | Our Approach | Stakeholder Engagement & Material Issues | 34 STAKEHOLDER ENGAGEMENT & MATERIAL ISSUES In this chapter: ƒ OUR APPROACH ƒ INITIATIVES ƒ MATERIALITY GRIDS Sustainability means meeting the needs of the present while leaving the world a better place for the future. That requires a sharp focus on the issues we face and an emphasis on collaboration, both within our organization and among our various stakeholders. Owens Corning works continuously to identify the material issues that most directly impact our operations, then we develop effective strategies to address them in partnership with a wide range of people and organizations. Photo submitted by: Andy Davis | Granville, Ohio, U.S. A bee pollinating a Rose of Sharon flower.

2021 Owens Corning Sustainability Report | Our Approach | Stakeholder Engagement & Material Issues | 35 OUR APPROACH Owens Corning is committed to objectively identifying material issues and evaluating their level of impact across our value chain. In support of this, Owens Corning is devoted to the assessment of our materiality matrix on a five-year cycle in accordance with AA1000 methodology. Our most recent Materiality Assessment was conducted in 2019. As part of our ongoing processes, we continue to evaluate the impact of any significant changes to our operations for potential risks or areas that could have a positive or negative impact on our stated goals. We have developed a process of stakeholder engagement, reviewing both internal and external groups. Photos submitted by: Susan Raneri | Massachusetts, U.S. Golf course, Northborough, Massachusetts. Karolina Koscianska | Trzemeszno, Poland (top, right) Mineral wool manufacturing plant in Hässleholm, Sweden. Danielle Wittorp | Dearborn, Michigan, U.S. (bottom, right) Flower garden.

2021 Owens Corning Sustainability Report | Our Approach | Stakeholder Engagement & Material Issues | 36 MATERIALITY & ENGAGEMENT INITIATIVES In 2021, we conducted another refresh of the 2019 Materiality Assessment, in which we sought to confirm the continued relevance of the existing Material Topics and their relative positioning within the materiality matrix visuals, for the company as a whole and broken out by region. The refresh and review process can be described in three steps: ■ Reassess scopes of material topics and input data for material topics. ■ Refresh the AI-driven aspects of the assessment to incorporate new industry benchmark, regulatory, news, and social data into the models. ■ A sustainability review to determine if the materiality assessment conducted in 2019 continues to accurately represent the company’s sustainability strategy, impacts, and goals, or if there has been a significant enough change to the company strategy or model inputs to require further revisions. In 2021, Owens Corning acquired vliepa GmbH, a German- based company specializing in the coating, printing, and finishing of nonwovens, paper, and film for the building materials industry. With this acquisition came an opportunity to reexamine our approach to sustainability materiality. We developed a process for assessing the materiality impact of new acquisitions, which looks at aspects such as the acquisition’s size and location, the products that they make, the markets they serve, their environmental footprint, and their social impacts such as safety and inclusion and diversity. This process enables us to determine if the acquisition is significantly impactful in scope or scale compared to our company, which can then lead to updates to our sustainability priorities and impacts that reflect both our existing company and the acquisition. Based on this review, it was determined that the vliepa acquisition did not require an update of our materiality assessment topic scopes, or relative matrix positions. This was due to vliepa’s alignment within Owens Corning’s existing product mix, as well as vliepa’s small size relative to Owens Corning as an enterprise. While this acquisition did not require an update to our sustainability materiality, it was an important step to develop a process for the consistent consideration of new acquisitions, as this process can potentially be used in the future as well. A sustainability review was conducted of the topic mapping, and the preliminary matrix data, taking into account the changes due to refreshing the data sources, and in the case of new Datamaran ontology, refreshing the underlying aspects of the material topics themselves. Through this assessment, it was determined that some topics did have slight movements in their weighting due to the new data. Despite these minor movements, the fundamental positions of the Material Topics, such as where topics lie in regions of the graph, were not significantly changed, and the Material Topics and their visual representations continue to represent Owens Corning’s material sustainability topics accurately. Photo submitted by: Leila Pourzahedi | Granville, Ohio, U.S. Squamish, British Columbia, Canada.