Startup Tools: 3D Printing

Printers and Services

3D Prototype Design Inc. is a rapid prototyping and 3d printing service provider. We were the first company in Canada to own and offer prototyping services with Fused Deposition Modeling, rapid prototyping technology since 1996. With our years of experience and knowledge it has provided us with an unparalleled understanding of the industry and capabilities, which is of great value to our customers. Coupled along with quality prototypes and a commitment to customer service and satisfaction, we have the ability to become a powerful part of your research and development team with our rapid prototype and 3d printing services.

How 3D Rapid Prototyping Design Can Help You

Our nylon prototypes offer several of the benefits of an injection-molded part, but without having to go to the expense of creating and injecting molds. Our nylon parts are durable as well as flexible. We can produce living hinges, snap fit components, functioning springs as well as prototypes that can be snap-fit, drilled and tapped. You can also run fluids through, sterilize and paint parts.

Testing your design with a prototype not only can save you time but an incredible amount of money. We have had many customers who integrated this step into their research and development process as the small costs associated with the parts is far less than what it would cost to fix a mistake once the molds have been created.

Medical Models using the Rapid Prototyping Process

3D Prototype Design has recently expanded our offerings to include something almost science fiction like. We can now create replica models of bones or injuries by using customer supplied CT scan data and our SLS rapid prototyping technology. It's almost like reaching into the body and being able to pull the injury out, hold it, pass it around or even rest it on the table! This application of technology has been very useful for surgeons with difficult cases as it allows them to examine the exact injury or issue without evasive surgery or discomfort to the patient.

See examples of our rapid prototyping capabilities

To see some amazing examples of our rapid prototyping capabilities, visit our recently updated website that now includes an expanded photo gallery featuring images of parts produced from CT scans, nylon components, rubber-like prototypes, colored parts and our 3D images that can be viewed with 3D glasses. If you don't already own 3D glasses, drop us a line and we'll send a pair out to you so you can have the full experience of the images.

At 3D Prototype our exclusive focus is on rapid prototyping and providing you with the best quality models and service available. Should you have any questions, require a quotation, or would like to discuss your options further, we would welcome the opportunity to become a part of your team and the rapid prototyping service bureau you can count on.

3D Prototype Design offers professional rapid prototyping

With more than 25 years in the field, 3D Prototype Design is a rapid prototyping company with the highest standards, along with a solid reputation for producing quality products at a reasonable cost.

The company is a pioneer in Canada is using rapid prototyping techniques to produce quality parts, and it continues to remain at the cutting edge of the latest technological advances.

We offer state-of-the-art rapid prototyping, professional product development, excellent quality materials, and follow-up service that keep us a step ahead of our competitors.

What are the advantages of rapid prototyping?

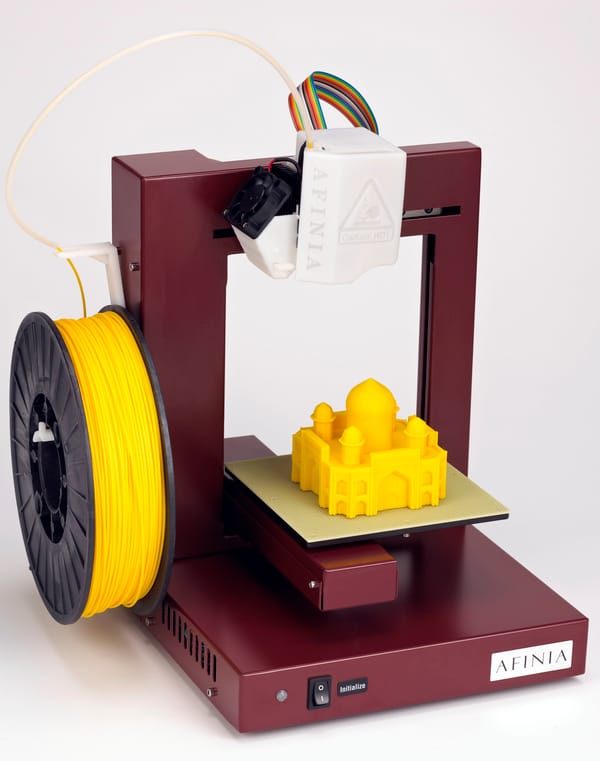

Rapid prototyping involves the production of three-dimensional parts or "prototypes" from computer aided drawings (CAD). Producing prototypes in this way has several significant advantages.

It allows the piece to be made without the cost of molds and tooling. This makes it easier to detect flaws or errors without the expensive process of producing new molds. The cost of research and development is reduced significantly by rapid prototyping because of the shorter time frame in producing a prototype.

Our rapid prototyping SLS process will provide you with a durable and accurate part that can be tested for fit and function. Being able to receive a working prototype quickly allows your company to test the part upon delivery and to detect any flaws or changes that need to be made.

Using our rapid prototyping process, it becomes possible to modify your product early in the development process, before going to the manufacturing stage. And all this can be done at a minimum of cost.

What is Selective Laser Sintering?

The technology employed by 3D Prototype Design Inc. in rapid prototyping is called Selective Laser Sintering (SLS). SLS technology, patented in 1989, uses a high-powered laser to fuse small particles of metal, plastic or glass into a three-dimensional object in nylon.

The SLS process takes data from a CT or MRI scan, and slices it into layers - one ultra-thin layer at a time - before the actual model or prototype is built.

SLS is an advance over the earliest rapid prototyping process, called Stereolithography (or SLA). This process uses a light-sensitive liquid polymer. The final product is more brittle than a model produced with SLS.

What can rapid prototyping produce?

There are a number of results that can come from rapid prototyping. These include prototypes that can be used as working parts, models for demonstrations and sales presentations, and variations of your design created as work on your product evolves.

3D Prototype Design's process can also produce specialized medical models from CT or MRI data that you provide. This rapid prototyping approach allows medical professionals to look at three-dimensional representations of a patients' damaged bones, for example.

These medical models produced by rapid prototyping can be used for instruction, to give students a three-dimensional, solid object to simulate an internal body part.

They can also be employed in legal cases to illustrate an injury quickly and effectively. The rapid prototyping model can communicate facts to a jury more clearly than having an expert interpret complex data.