Startup Tools: Low Cost CAM Software

You have modest goals- take a CAD file and get your mill to cut it. You don't want to become an expert on CAM software- you want parts today.

MeshCAM is made for people who just want to make parts now.

Here's the MeshCAM process:

- Load a file from almost any CAD program

- Build an efficient toolpath with minimal input

- Save gcode that works on your CNC machine

Don't let the simplicity fool you; MeshCAM has lots of flexibility and options for very advanced machining.

MeshCAM works with your CAD

MeshCAM works with almost every 3D CAD program by opening the two most common 3D file formats, STL and DXF.

Rhino, Solidworks, Autodesk Inventor, Viacad, Blender, Sketchup, Tinkercad, Autocad, Alibre, ZBrush, and many more work perfectly.

If you just want to make 2D parts without using a 3D CAD program, you can load 2D DXF files (in R12 format) and extrude them to a 3D part.

No CAD- No Problem

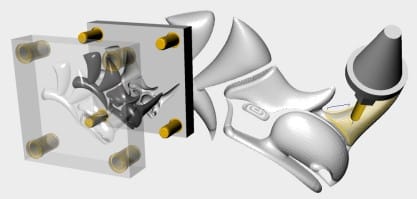

Sometimes you need a part that cannot be designed with a traditional CAD program.

Sometimes you don't even have a CAD program.

If this sounds like you, don't worry- open any image file (JPG, BMP, or PNG) and MeshCAM converts it to a 3D surface that can be machined directly.

Users have come up with incredible uses for this feature to make parts that would be almost impossible with a traditional CAD program.

No machining knowledge required

The worst part of any new CNC software is being confronted by a wall of settings to create a toolpath.

Stepover, stepdown, waterline, threshold angles... Do you want to learn a whole new language just to get your first toolpath?

MeshCAM has an Automatic Toolpath Wizard that picks as many of those values as possible so that you don't have to.

You just pick the cutters, tell MeshCAM the desired quality level, and it will analyze the model to pick values to get you started. You can tweak them to make them better or use them as-is.

If you already know what you're doing then don't worry- you still have complete control over all of your toolpath settings.

Machine almost anything

Every part requires a slightly different approach to machine it efficiently. If you CAM software doesn't give you enough toolpath strategies then you'll spend more time to machine your part or you'll give up finish quality. This is not something you have to worry about with MeshCAM.

MeshCAM has more toolpath options that any competing CAM program.

- Parallel Roughing (planar and 3D)

- Contour Offset Roughing (Planar and 3D)

- Parallel Finishing ( X or Y direction)

- Waterline Finishing

- Pencil Finishing

This combination of toolpaths will machine almost any part you can imagine.

Automatically calculate the machining area

A lot of CAM software makes you define exactly the area that you'd like to machine.

This is a waste of your time- your CAM software already has the information it needs to determine the machining area automatically. It just doesn't do it.

MeshCAM reduces this to a simple check box- tell it to machine the whole stock or tell it to machine only the area covered by your part.

That's a lot of hassle reduced to a single checkbox.

...Or tell MeshCAM exactly where you'd like to machine

There are times when you do want complete control of the area to be machined- MeshCAM makes that easy too.

You can define specific regions to be machined by clicking around the 3D window, or by loading an outline from your CAD program.

You'll find this to be a really useful feature when you need to re-machine a section of a part or when you need to machine a small, detailed section of your part without having to machine the whole thing.

Eliminate complicated fixtures

Some parts are very difficult to machine because they're very difficult to hold down. Clamps and vises get in the way and turn what should be an easy job into a complicated one.

MeshCAM lets you add supports (or tabs) to your part so that it remains connected to the stock during machining. The supports hold the part in place so you can keep the cutter away from your vise. (...or anything else you don't plan on cutting)

MeshCAM does this without help from your CAD program so it doesn't depend on anything but MeshCAM itself.

Machine HUGE parts

MeshCAM has been designed from the start to support HUGE 3D files. Huge in physical size and huge in file size.

There are users making boats and large museum exhibits in MeshCAM with no trouble.

There are also jewelers and engineers making incredibly detailed parts with file that contain millions of polygons with great results.

The key to this is that MeshCAM supports 64 bit CPUs so that it can use as much memory as your PC can hold. You're not limited to 2GB of RAM like the older 32-bit Windows- MeshCAM can use it all.

Calculate toolpaths more quickly

Modern PC's have more than one processor in them even though most software won't take advantage of more than one. Why would most software not take advantage of everything your computer has to offer? because it's incredibly difficult to do it and make it work well.

MeshCAM was rewritten years ago to take advantage of all of the processors in your PC. In fact, it was one of the first CAM programs available to do this.

MeshCAM splits up many of the toolpath calculations between multiple processors to reduce the time that you're waiting for the results.

This cuts your waiting time from minutes to seconds in some cases.

Use the right cutter for a job

MeshCAM Supports ALL of the common cutter types:

...and any of these can be straight or tapered.

Supporting all of these cutters creates a lot more work for the people developing CNC software but it's worth it- using the right cutter lets you finish a job more quickly and with better results.

Good CAM software should never limit what cutters you can use and MeshCAM won't limit you.

Automatically check for shaft collisions

MeshCAM checks for gouging against the cutter shaft in addition to the normal checking against the part that's meant to cut. This is especially important if you regularly use small cutters where the shaft can be much bigger than the flutes.

At every point on the part, MeshCAM checks that it will not cut so deep that the part will be gouged by the shaft or any part of the cutter.

MeshCAM does everything it can to protect your cutters and your part.

Works with your CNC machine

MeshCAM has a built-in post processor to transform the gcode to work with your machine. It supports lots of machine types as-is and it can be extended to support most other

If your CNC machine takes normal gcode then it will work with MeshCAM.The post processor format is fully documented in the help file so you can make changes if you find the need.

If you find problems with the built-in post processors then email us, we'd be happy to see if you can make modification for you for free.

See what your part will look like when it's done

Sometimes you don't have time to run a toolpath to see how it will turn out. If you need something faster then you can check out a CNC Simulator like Cutviewer.

Cutviewer shows you a complete 3D simulation of what your part will look like after running it in your CNC machine.

MeshCAM is designed to integrate with Cutviewer so that you can load the gcode immediately without having to reenter any information about cutters or stock size.

This is the absolute fastest way to see what your parts will look like with no wasted time, cutters, or stock.

Try it before you buy it

You should never buy software without trying it and you should never try software only with the sample files you're given. You need to try it with your files.

You can try MeshCAM for 15 days with no restrictions, totally free. Click here if you'd like to get started.

You can complete a project with MeshCAM before you ever have to pay for it.

Honest, open pricing

Look around for pricing for other CNC software and you'll see a lot of "Request a quote" or "Call us" buttons.

Do you really want to get on the phone with a sales guy just to get a price?

Can you even be sure that you're getting the best price?

MeshCAM pricing is totally open and transparent. It's $250. No calls, no requesting quotes.

You can buy it online without talking to sales people.

No annual maintenance fees

Here's another favorite tactic of CNC software companies- charging you every year to keep your software active and updated.

You already paid for it, why should you have to pay every year?

If you buy MeshCAM, you own it. You will not pay yearly fees to keep it active.

Free updates

Here's the update policy for MeshCAM:

- You will get all updates to the current version of MeshCAM (Version 5 and the soon-to-be-released Version 6) forever.

- If a new version is released within a year of your purchase, you'll get it for free.

This is the most generous update policy in the CNC software industry.

Works on most PCs and Macs

On Windows, MeshCAM runs on XP, Vista, Window 7, or Windows 8. It requires a minimum of 1GB or RAM but 2GB or more is recommended.

If you have a Mac, you can join the early-access preogram to get the new MeshCAM for Mac. MeshCAM for Mac requires OSX 10.7 or higher and a minimum of 2GB of memory.

If you have a Linux machine, users have had good luck running MeshCAM under Wine on Ubuntu version 10. Check out the Linux CNC page for more details.

MeshCAM will be around for the long run

MeshCAM was first put online in 2004 so it's not the new kid on the block.

Since then, there have been 5 major versions, hundreds of releases and tens of thousands of downloads.

We have plenty of ideas left and a big todo list. We're going to be doing this for a while.

Try it free today

Go to the download page to get a totally free 15 day trial. You'll be up and running instantly, with no limitations. If you have any questions at all, contact us!

It's no problem if you need more time to try MeshCAM. Just email us when the trial code expires and we'll send you another one (or two).