Golden Bridge Welding Materials Manual

Table of contents Preface ............................................................................................. 1 Classification of "Golden Bridge Welding Materials ..................... 3 4 Featured products of the company .......................................... . Welding rods Brief introduction of welding rod, coating and slag series ............. 6 Golden Bridge 8 Instructions on structural steel welding rods ................................... Welding Materials Concise table of weathering resistant steel and other low-alloy corrosion resistant steel welding rods ........................................ 77 ■ Product sample ■ Instructions on heat resistant steel welding rods ............................. 89 Instructions on low-temperature steel welding rods .......................... 113 1㈀㈀ Instructions on stainless steel welding rods ............................. Schae昀昀er Organization Chart ................................................ 125 Su爀昀acing welding rods ....................................................... 183 Cast iron welding rods ....................................................... ㈀㈀5 Special welding rods for pipeline welding .................................... 232 Welding wires 4 Gas-shielded welding wires ................................................. 24 Argon arc welding wires ..................................................... 欀 Submerged arc welding wires .............................................. 3㌀㠀 Instructions on flux used in submerged arc welding ................. ㌀㠀5 Flux-cored welding wires ................................................... .4㈀ Aluminum and aluminum alloy welding wires ......................... 㠀 4 Quoted standards ................................................................. 4 Symbol description ................................................................ 487 TIANJIN GOLDEN BRIDGE WELDING MATERIALS GOURP CO.,LTD 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - -

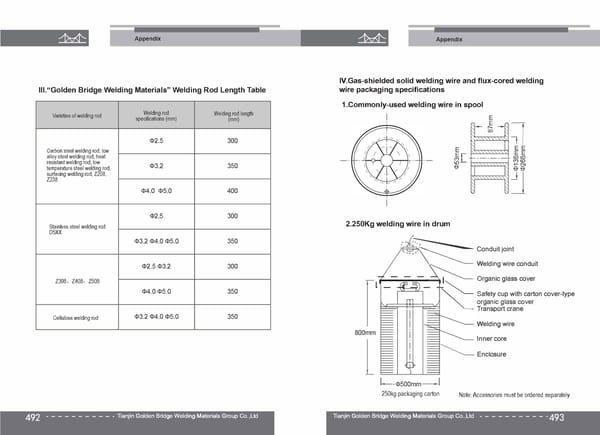

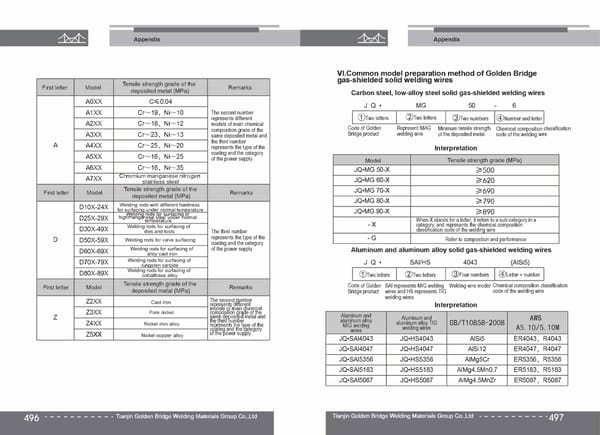

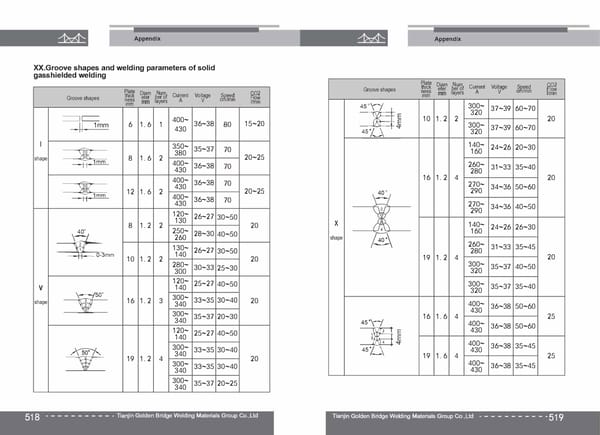

Preface Appendix Tianjin Golden Bridge Welding Materials Group Co., Ltd. is a large enterprise I .List ofThose Certified by the Classification Society .............................. .. 4㠀㠀 engaged in professional research and production of welding materials.The II.Golden Bridge Welding Materials Package Weight Table ......................... 491 "Golden Bridge Welding Materials" brand is well-known both at home and " 111. Golden Bridge Welding Materials" Welding Rod Length abroad, its technology can be traced back to welding materials of the Table ................................................................................... 㤀㈀ "Lianhuan" brand in the early 1950s, which are deeply loved by a large number 4 IV.Gas-shielded solid welding wire and flux-cored welding wire of welders. The Group currently has 2 branches, 3 joint ventures, 15 packaging specifications .............................................................. 4㤀㌀ subsidiaries and 12 production bases. Mr. Hou Lizun, the founder of the Group, V.Model preparation instructions of Golden Bridge welding rods .................... 㤀㐀 has been engaged in welding material manufacturing industry for more than 70 4 VI.Common model preparation method of Golden Bridge gasshielded years. He owns multiple proprietary technologies in the fields of raw materials, solid welding wires .................................................................... 49 paint slag series, production equipment, production technology, etc., which has 7 VII.Model preparation method of Golden Bridge flux-cored laid a solid foundation for development of welding technologies in China. Mr. welding wires ......................................................................... 4 Hou Lizun was awarded the highest honor in Chinese welding industry - "China VIII.Common model preparation method of Golden Bridge Welding Lifetime Achievement Award" . Up to now, Mr. Hou Lizun is the only submerged arc welding wires - flux ................................................... 愀넀 one person who has won this great honor in Chinese welding material IX.Storage of welding materials ........................................................ 䈀䨀1 manufacturing industry. X.Hardness Number Comparison Table ............................................... 5 㐀 Our Group is capable of producing more than 400 varieties of welding materials XI.Common Units and Conversion Table ............................................. BJ? such as various welding rods, gas-shielded solid welding wires, XII.Length Unit Conversion Table(mm and inch) ..................................... 㠀 gas-shieldedand self-shielded flux-cored welding wires, submerged arc welding 5 XIII.International standard on the di昀昀usible hydrogen content of wires, flux, welding strips and aluminum welding wires. Products are complete welding materials (deposited metal) ................................................... 5昀꼀 in varieties and specifications and the annual production and sale volume of XIV.Preheating temperature required is determined based on welding materials of the Group reaches more than 1.4 million tons. It is the first carbon equivalent Pcm of steel, di昀昀usible hydrogen content [H] of welding material enterprise in the world whose production and sale volume the specific welding material and plate thickness 㔀 ................................... 5昀꼀 exceeds one million tons, and it ranks first in the industry for 19 consecutive XV.Common welding defects ......................................................... 510 years. Products are widely applied to the manufacturing of ships, bridges, boiler XVI.Common straight carbon steel standard and comparison and pressure containers and rolling stock, and petroleum, chemical between new and old low-alloy structural steel standards ........................... engineering, metallurgy, architecture and other fields. In addition, the Group is 513 XVII.Welding rods recommended for commonly-used carbon able to undertake the research, development and production tasks of welding 514 steel and low-alloy steel ............................................................... materials with special requirements of users, actively research and develop new XVIII.Consumption of filler materials .................................................. 515 welding materials so as to satisfy national demands for high-end equipment XIX.Recommended groove shapes of welding rod arc welding manufacturing and technological development and develop non-ferrous and 1 7 based on plate thickness ............................................................... 5 white environmental-protection welding materials to meet the needs of national XX.Groove shapes and welding parameters of solid gas-shielded key projects. It serves national economic development and national defense welding ................................................................................. 518 construction. Its sales network covers the whole country and its products are XXI. Groove shape and welding process parameters of CO2- exported to more than 100 countries and regions in the world. shielded flux-cored welding ............................................................ 5夀怀 The company has a technology research and development team full of 4 XXII.Generation and prevention of general welding defects .......................... 52 innovative spirit, constantly exploring and pushing forward the forefront of technology. It owns a complete and strict quality management system, as well as objective and scientific inspection and testing mechanism, accompanied with complete testing equipment, which has reached the world advanced level. 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 1 - - - - - - - - - - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd

Classification of "Golden Bridge Major products have been certified by a series of classification societies, such Welding Materials" as CCS,LR, BV, ABS, DNVGL, NK, KR, RS, RINA and BKI and obtained TOV, DB and CE certification. The quality system has not only passed ISO9001 quality certification, but also passed quality certification in fields of nuclear ■ Structural steel weldin rods � (Including weathering resis ant steel and low-alloy corrosion power, boilers and ships. resistant steel welding rods) Golden Bridge Welding Materials Group is dedicated to revitalizing national ■ industry evolution, conforming to national economic construction and 氀氀 ■ Heat resistant steel welding rods development need, actively accelerating its transformation and upgrading pace, 儀⸀ 㨀昀 strengthening management system and mechanism innovation and building the 愀焀 ■ Low-temperature steel welding rods fine and information-based scientific management model; adjusting the product structure, increasing investment in science and technology, realizing 儀⸀ ■ Stainless steel welding rods ⼀儀 achievement transformation and increasing the brand value; formulating the intelligent production plan and promote full-automatic production equipment ■ Surfacing welding rods coverage; adhering to the sustainable development road of green, environmental protection and cleaner production; adhering to the human capital ■ Cast iron welding rods cultivation engineering to ensure the long-term development of the company. ■ Special welding rods for pipeline welding ■ Gas-shielded welding wires The mission of the Group is: Revitalize national industry ■ ■ Solid welding wires ⴀ嬀 evolution, repay country with optimal welding materials. 甀甀 氀氀 ■ Submerged arc welding wires The vision of the Group is: Innovation leads industry 儀⸀ development, create new era of welding consumables. 㨀昀 CO2-shielded flux-cored 愀焀 welding wires The core value of the Group is: Endless in pursuing high quality ■ Flux-cored welding wires 甀甀 ' ⴀ嬀: Self-shielded flux-cored products, flawless in serving for our customers. 氀氀 ⼀儀 ■ Argon arc welding wires welding wires ■ Aluminum and aluminum alloy welding wires ■ Flux (sintered flux) 2- - - - - - - - - - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 3

Featured products of the company welding wire, the stainless steel flux-cored welding wire with white weld joint and the cryogenic stainless steel flux-cored welding wire. Considering the deposited metal of the conventional stainless steel flux-cored 1.Self-shielded flux-cored welding wires: JC-28, JC-29, JC-29Ni1, welding wires (Q-308L, JQ-309L, JQ-316L, JQ-317L, JQ-347L, JQ-2209, etc.) has JC-30,JC-80, etc. stable mechanical properties, this type of wire has good intergranular corrosion This series of welding wires is flux-cored welding wire of the high-toughness resistance, crack resistance and operation performance.Besides, its welding efficiency self-shielded series, which is researched and developed in an innovative manner is also high. based on the actual pipeline construction demands and the current market status in In addition to features of the conventional stainless steel flux-cored welding wires, after China. Considering gas protection is unnecessary during welding, it is quite suitable welding of the stainless steel flux-cored welding wire with white weld joint (LH-308L, for field construction. As the only successful bidder of similar products in China, it has LH-309L and LH-316L), the generated weld joint appearance is free from the oxidation been successfully applied to the national key project "Line II of West-East Natural Gas tint (bright silver), therefore, the weld joint cleaning and processing procedures Transmission Project" . Now, it is also widely applied to "Line Ill of West-East Natural required after welding of conventional stainless steel welding materials is unnecessary Gas Transmission Project" and "China-Myanmar Pipeline Project" . In addition, it has for this type of welding wires. been applied to metallurgical blast furnace installation, high-rise steel structure The cryogenic stainless steel flux-cored welding wire (JQ-308LT and JQ-316LT) is construction, offshore oil platform construction, etc. mainly applied to welding of structural materials used in cryogenic low-temperature environment in the CNG (compressed natural gas),LNG (liquefied natural gas) and 2.Metal-power gas-shielded flux-cored welding wires: LPG (liquefied petroleum gas) storage and transportation equipment field, because it JQ·YJ503MX-1,JQ.YJ621K2-1Q. ° has good and stable low temperature impact performance at -196 C. This type of welding wire is characterized by good welding performance.high deposition e昀昀iciency, low welding spatter, little slag and stable arc. It is applicable to 5.High-strength gas-shielded solid welding wires: JQ.MG60-G, single-wire or double-wire downward welding or flat fillet welding. Automatic JQ.MG60-G-1, JQ.MG70-G, JQ.MG70-G-1, JQ.MG70-G-2, high-speed welding is achievable and it also has good anti-porosity performance when JQ.MG80-G,JQ.MG80-G-1, JQ.MG90-G, etc. being applied to welding of steel plates covered with primer and rusty surface. The Mn-Si-Ni-Mo-Cr alloy system is adopted for this series of welding wires for reinforcement so that the tensile strength can reach 620-890 MPa. After addition of 3.Ultralow-hydrogen high-toughness structural steel welding proper amount of refined grains of microelements, the low-temperature impact rods:J507RH, J557RH, J607RH, JQ.J607RHQG, J707RH, J807RH, toughness of the deposited metal becomes good. This series of welding wires is etc. characterized by good operability, stable arc, low spatter and beautiful weld joint This series of welding rods is of ultralow-hydrogen, high-toughness type,characterized appearance. Now, it is widely applied to industries of coal machine, heavy-duty by good welding performance, stable arc, uniform coating melting, low spatter, easy machinery, water and electricity, etc. slag removal and beautiful weld joint appearance;in addition, the deposited metal contains extremely low diffusible hydrogen.which makes it have good crack resistance, 6.Welding wires for automatic welding of pipeline as well as comprehensive mechanical properties and excellent low temperature impact This series of welding wires for full-automatic welding of pipeline can be classified into toughness under low temperature. Its current adjustment range is wide and all-position three categories: Metal-powder-cored flux-cored welding wires (JQ-70M and JQ-80M), welding is possible. ° rich argon-shielded flux-cored welding wires(JQ-81T1 M and JQ-91T1 M) and JQ.J607RHQG still owns relatively high impact toughness at -60 C . ° gas-shielded solid welding wires (JQ.X70 and JQ.X80). These three categories of J707RH still owns relatively high impact toughness at -50 C. welding wires are especially suitable for semi-automatic and full-automatic root 4.Products of stainless steel flux-cored welding wire series: welding, filling and cosmetic welding of long-distance transport pipelines. Among This series of welding wires is of CO2-shielded ultra-low carbon stainless steel which, JQ-81T1M gas-shielded flux-cored welding wires and JQ-70M flux-cored type and it is classified into the conventional stainless steel flux-cored 4- - - - - - - - - - - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 5

Instructions on structural ⼀戀 steel welding rods ∀䌀 0 Structural steel welding rods are suitable for welding of carbon steel and ⸀尀 low-alloy steel. 䌀氀 Selection of welding rods is based on chemical composition of steel, as well as 䌀㨀 requirements for mechanical properties and crack resistance.At the same time, ∀䌀 factors such as welding structure, steel plate thickness, working conditions, stress, and performance of welding machines shall be considered for comprehensive 1 analysis. If necessary,conduct the welding test, formulate corresponding process 儀⤀ measures,and then determine the selected welding rods. ⸀猀 1.For welding of structural steel, the welding rod corresponding to the strength grade of the steel ⼀戀 is generally selected. At the same time.considering steel with complex structure, thick plate, large 挀漀 ⸀尀 rigidity.dynamic load and poor weldability, the low hydrogen welding rod characterized by good 琀昀 plasticity, high impact toughness and good crack resistance is generally selected. When there are 尀尀 0 special requirements for the welding position, corresponding special welding rods, such as 琀昀 vertical downward welding rods, backing welding rods, and all-position welding rods for pipelines, ⸀尀 尀尀 shall be used. Iron-powder welding rods can be selected in order to increase welding efficiency. ⼀戀 2.lf the weld joint cools down within a short period, has high strength and is easy to crack, the - 0 welding rod whose strength is one grade lower than that of the base metal can be selected. 3.ln case of multi-layer welding of thick plates or normalizing treatment after welding, it is � ⸀ necessary to prevent occurrence of too low weld joint strength. 4.For dissimilar steel welding between low carbon steel and low-alloy steel or between low-alloy ⸀猀 steel and low-alloy steel, the welding rod corresponding to the steel with low strength grade is 氀氀 ⼀戀 generally selected.and considering the low-alloy steel factors, the low-hydrogen type is preferred. ·㨀鸀 5.For welding of medium-carbon steel, the high carbon content of steel increases the welding 䌀㨀 ⴀ㸀Ⰰ-ⴀ⬀-ⴀ堀娀ꄀ-ⴀ⬀-⬀ⴀ娀ꄀ-ⴀ⬀-⬀ⴀ娀ꄀⴀꄀⴀ⬀-⬀ⴀ-ⴀꄀⴀ⬀---ⴀꄀⴀ⬀-ⴀⰀ cracking tendency. Therefore, the low-hydrogen welding rod is used in general, supported by 0 椀숀挀Ⰰ ⸀ ⸀ u preheating, slow cooling and post-heating methods, as well as appropriate welding processes. u u u u u u u u u ⸀ u 愀㨀 愀㨀 0 0 0 0 0 0 0 0 0 0 愀㨀 0 ⸀儀 � g 6.Cast steel has poor weldability, because its carbon content is generally high, thickness of the u u 愀Ⰰ� u ⸀儀 u ⸀儀 ⸀儀 ⸀儀 ⸀儀 ⸀儀 u u u ⸀儀 ⸀儀 workpiece is large, the structure is complicated and cracking traces can be easily generated 0 0 0 㰀笀 during welding. When the cast steel contains many alloying elements, such properties are more 㬀㬀 � 㰀笀 㰀笀 㰀笀 㰀笀 㰀笀 㰀笀 㰀笀 㰀笀 㰀笀 㰀笀 㰀笀 �⸀䔀 prominent. In general, low-hydrogen welding rods are selected, and meanwhile.preheating, slow cooling and other methods, together with corresponding welding processes are adopted. 7.ln order to ensure welding quality, the weld crater of the workpiece shall be thoroughly cleaned, free from oil stain, rust, water, paint and dirt, which is quite important for application of low-hydrogen welding rods. ° 8.For low-hydrogen welding rods, they must be baked at 350-400 C for 1 h before welding, and bake them immediately before use. Otherwise, a series of defects such as pores, slag inclusions ∀儀 ∀儀 ℀甀 ℀甀 ∀儀 and cracking traces, are easily generated. Cellulose welding rods generally do not need to be 猀琀 猀琀 � � 0 0 0 N N baked. Once they are affected with damp, they shall be baked at the temperature specified by the ∀儀 ∀儀 ∀儀 ∀儀 0 0 0 ℀甀 ℀甀 ℀甀 猀琀 猀琀 猀琀 猀琀 instructions before welding. However, too high temperature will damage their welding w w w w w w w performance. 9.For low-hydrogen welding rods, repeated baking is generally not allowed to prevent the coating from getting crisp and peeling off 0 堀儀 堀儀 ℀甀 椀甀 ꜀✀ 10.The welding current specified in the instructions is the reference value.which shall be 䤀儀 � 䤀儀 0 䤀儀 z 愀椀 䰀䰀 愀椀 N 䤀儀 specifically controlled in actual operation. For example, for workpiece preheating, the current can 䰀䰀 猀琀 � lⴀ퐀 䰀䰀 䰀䰀 䰀䰀 0 N be 5%-15% lower than the normal current; the current required for vertical welding and overhead � N � ℀甀 0 氀ꀀ N � ⠀ 猀琀 ⴀ夀 ℀甀 0 0 N 猀琀 N welding is 10%-15% smaller than that for downward welding; and the current required for DC is 堀儀 ⴀ夀 ⴀ夀 ⴀ夀 ℀甀 ℀甀 猀琀 N ∀儀 ⴀ夀 ⴀ夀 ⴀ夀 about 10% smaller than that for AC. When a DC welding machine is used, pay attention to the 猀琀 ㈀ⴀ ⴀ夀 polarity connected for welding as specified in the instructions; otherwise the welding process may be affected 儀⤀ 挀Ⰰ M M M N N 㰀鬀 ∀✀ N N N N 0. 8 - - - - - - - - - - - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 9

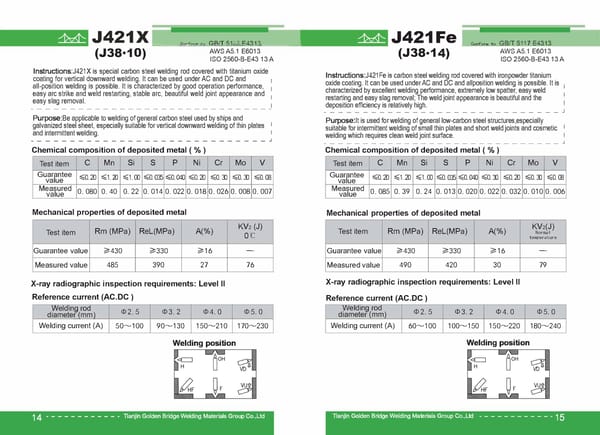

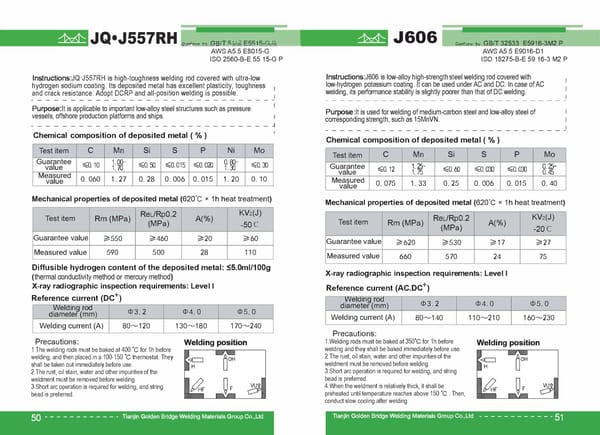

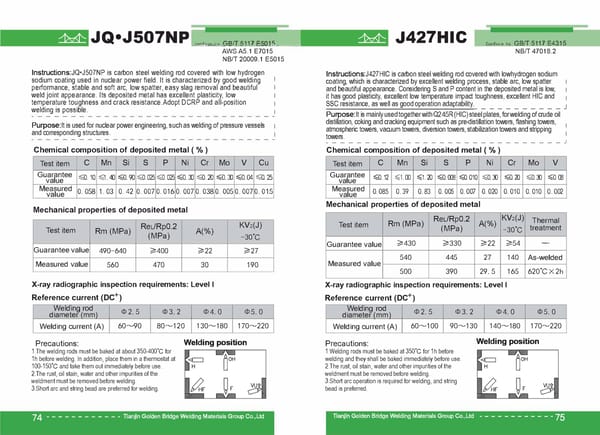

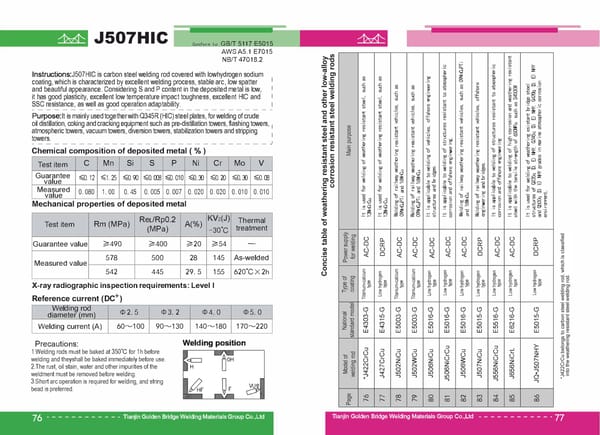

J422 J421Fe16 Conform to GB⸀茀 511㜀⸀ E4303 Conform to GB⸀茀 511㜀⸀ E4324 ISO 2560-B-E43 24 A ISO 2560-B-E 43 03 A (J40•50) J421Fe18 lnst爀甀ctions:J421 Fe16 and J421 Fe18 are carbon steel welding rods covered with lnst爀甀ctions:J422 is carbon steel welding rod covered with titanium-calcium iron-powder titanium oxide coating. They can be used under AC and DC and are coating. It can be used under AC and DC and all-position welding is possible. It applicable to downward welding and flat fillet welding. It is easy to restart a weld, owns excellent welding performance and good mechanical properties; it is spatter is low and slag removal is easy. The weld joint appearance is beautiful, and the characterized by stable arc, low spatter, easy slag removal, as well as easy weld 1 restarting; the weld joint appearance is beautiful, wide, narrow, thin and thick weld deposition efficiency respectively reaches about 160% and 180%. _____________________________ J ripples are all possible.welding operation is easy with high e昀昀iciency. Purpose:They are used for downward welding and flat fillet welding of general : 1 low-carbon steel structures. Pu爀瀀ose:lt is used for welding of relatively important low-carbon steel structures, and -----------------------------� 1 low-alloy steel structures of low strength grade such as Q235, 09MnV and 09Mn2. _____________________________ I Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn Cr C Si s p Ni Mo V Test item Mn Cr C Si s p Ni Mo V Test item Guarantee �0.㐀怀 �0.20 �1. �0.氀氀 �0.㈀ �0.氀氀 �0. �o. ㌀攀 �1.㈀ value Guarantee �1. �O. 氀氀 �0.20 �0.氀氀 �0. �o. 㐀怀 �1.20 �o. 20 �-㌀攀 value Measured 0.077 0. 78 0.40 0.014 0.023 0.025 0.035 0.007 0.008 value Measured 0.078 0.39 0. 18 0.018 0.023 0.020 0.032 0.008 0.005 value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) KV2 (J) Rm (MPa) ReL(MPa) A(%) Rm (MPa) ReL(MPa) A(%) Normal Test item Test item temperature 0뀀䌀 -20뀀䌀 - �16 �20 �430 �330 �430 �330 �27 Guarantee value �47 Guarantee value 510 420 26 96 475 29.5 97 390 73 Measured value Measured value X-ray radiographic inspection requirements: Level II X-ray radiographic inspection requirements: Level II Reference current (AC.DC ) Reference current (AC.DC ) Welding rod Welding rod 䌀䐀3. 2 䌀䐀4. 0 䌀䐀S. 0 䌀䐀2. 0 䌀䐀 2. 5 䌀䐀3. 2 䌀䐀4. 0 䌀䐀S. 0 diameter' (mm) diamete爀∀(mm) Welding current (A) Welding current (A) 110~160 160~240 210~270 40~70 60~100 80~140 160~220 200~240 Welding position Welding position - - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 17 - - - 1 6 - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - -

J426 J422Fe Conform to GB/⸀吀 511㜀⸀ E4303 Conform to GB/T 511㜀⸀ E4316 ISO 2560-B-E 43 03 A ISO 2560-B-E 43 16 A (J48•46) lnst爀甀ctions:J422Fe is carbon steel welding rod covered with ironpowder lnst爀甀ctions:J426 is carbon steel welding rod covered with lowhydrogen potassium titanium-calcium coating. It can be used under AC and DC and all-position welding is coating. It can be used under AC and DC and allposition welding is possible. Its 1 1 possible. It is characterized by stable arc, low spatter, easy slag removal, as well as deposited metal has excellent mechanical properties and crack resistance, as well as easy weld restarting; The weld jointappearance is beautiful and the deposition efficiency I good low temperature impact toughness. 1 is relatively high. Purpose:lt is applicable to welding of relatively important lowcarbon steel structures. Pu爀瀀ose:lt is used for welding of important low-carbon steel and lowalloy steel structures such as ships, bridges and pressure vessels. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - _I _____________________________ I Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn Mo Mn Mo C Si s p Ni Cr V C Si s p Ni Cr V Test item Test item Guarantee Guarantee �0.㐀怀 �0.㐀怀 �0.20 �1.㈀ �1. �o. 0㌀㔀 �0.氀氀 �0.㈀ �0.氀氀 �0. �o. 20 �1.20 �1. �O. 氀氀 �0.20 �0.氀氀 �0.䌀䔀 �-0㌀㔀 value value Measured Measured 0.080 0.40 0. 21 0.019 0.023 0.015 0.026 0.007 0.008 0.062 0.83 0.30 0.010 0.019 0. 031 0.030 0.007 0.018 value value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) KV2 (J) Test item Rm (MPa) ReL(MPa) A(%) Rm (MPa) ReL(MPa) A(%) Test item 0뀀䌀 -30뀀䌀 Guarantee value �20 �20 �27 �430 �330 �27 �430 �330 Guarantee value 490 29 79 172 390 495 395 33 Measured value Measured value X-ray radiographic inspection requirements: Level II X-ray radiographic inspection requirements: Level II + Reference current (AC.DC ) Reference current (AC.DC ) Welding rod Welding rod 䌀䐀3. 2 䌀䐀4. 0 䌀䐀S. 0 䌀䐀 2. 5 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀S. 0 diameter (mm) diamete爀✀(mm) 80~140 140~220 180~240 60~100 80~140 110~210 160~230 Welding current (A) Welding current (A) Welding position Welding position Precautions ° 1 Welding rods must be baked at 350 C for 1 h before welding and they shall be baked immediately before use. 2.The rust, oil stain, water and other impurities of the weldment must beremoved before welding. 3Short arc operation is required for welding, and string bead is preferred. - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 19 - - - 18 - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - -

J427 J427 � D -Con=fo=,m-to㨀褀/�T�s1�1㜀⸀�E4=31㴀㔀 ___ _ Conform to GB/I 511㜀⸀ E4315 ISO 2560-B-E 43 15 A I SO 2560-B-E 43 15 A (J48•47) lnstructions:J427D is special carbon steel welding rod for backing welding covered lnstructions:J427 is carbon steel welding rod covered with lowhydrogen sodium with low-hydrogen sodium coating. Adopt DCRP. The characteristics of the welding rod coating. Adopt DCRP and all-position welding is possible. Its deposited metal has include: The arc has certain blowing force. When backing welding is performed, adopt 1 excellent mechanical properties and crack resistance, as well as good low temperature single-side welding with back formation. In _addition, arc is stable, slag removal is easy 1 impact toughness. and the weld joint generated on the back side 1s beautiful. Select appropriate process to 1 prevent defects such as pores and slag inclusion. 1 --------------------------- Purpose: It is used for welding of important pressure load or low:carbon steel . thick-plate structures and low-alloy steel structures such as machinery, ships, bridges Purpose:lt is exclusively used for backing welding of carbon steel and low-alloy steel : 1 and pressure vessels. st sp c rr s e c n n t r _ _____________________________ j � � 㨀㨀' � � 㨀开 � � � � � � _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ , Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) C Mn Si s p Ni Cr Mo V Test item C Mn Si s p Ni Cr Mo V Test item Guarantee �0. 䤀ꘀ �0. 䤀ꘀ �0. 㐀0 �0.20 �1.㈀ �1. �0.㈀ �0. �o. 0㔀 value Guarantee �0. 0㔀 �0. 䤀ꘀ �0. 㐀0 �0.㈀ �1.20 �1. �0.氀氀 �0.20 �0. value Measured 0.056 0. 70 0.50 0.012 0.020 0.032 0.032 0.005 0.015 value Measured 0.075 0.84 0.60 0.010 0.022 0. 031 0.030 0.007 0.013 value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) Test item Rm (MPa) ReL(MPa) A(%) KV2(J) -30뀀䌀 Test item Rm (MPa) ReL(MPa) A(%) 뀀䌀 -20 -30뀀䌀 Guarantee value �20 �430 �330 �27 Guarantee value �20 �430 �27 �330 �47 520 420 58 34 Measured value 525 440 178 142 30 Measured value X-ray radiographic inspection requirements: Level I + X-ray radiographic inspection requirements: Level I Reference current (DC ) + Reference current (DC ) 瘀瘀eldmg rod 䌀䐀 2. 5 䌀䐀 3. 2 䌀䐀4. 0 diamete爀∀ (mm) Welding rod 䌀䐀2. 5 䌀䐀3. 2 䌀䐀4. 0 䌀䐀S. 0 diameter' (mm) 60~100 80~140 110~210 Welding current (A) 60~100 80~140 110~210 160~230 Welding current (A) Precautions: Welding position ° 1 Welding rods must be baked at 350 C for 1 h before welding -- -- 蠀蜀蠀蠀褀蠀 蜀蘀 Welding position 褀蠀 and they shall be baked immediately before use. Precautions: ° 2.The rust, oil stain, water and other impurities of the 1 Welding rods must be baked at 350 C for 1 h before weldment must be removed before welding. welding and they shall be baked immediately before use. 3Short arc operation is required for welding, without swing, 2.The rust, oil stain, water and other impurities of the and string bead is preferred. weldment must be removed before welding. 4.Arc strike shall be carried out outside the groove and the 3Short arc operation is required for welding, and string arc shall be extinguished at another place after the molten bead is preferred. bath is full - - - - - - - - - - 21 Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd 20 - - - - - - - - - - -

J427Ni J501Fe Conform to GB⸀茀 511㜀⸀ E4315 Con orm to GB⸀茀 511㜀⸀ E501㬀㐀 ISO 2560-B-E 43 15 A AWSA5.1 E7014 ISO 2560-B-E 49 14 A 1 lnst爀甀ctions:J427Ni is carbon steel welding rod covered with lowhydrogen sodium lnst爀甀ctions:J501 Fe is carbon steel welding rod covered with iron powder titanium I coating. Adopt DCRP and all-position welding is possible. It is characterized by oxide coating. The deposition efficiency is about 110%.11 can be used under AC and DC excellent low temperature impact toughness of the weld metal. and all-position welding is possible. It is characterized by excellent welding performance,! 1 stable arc, low spatter and easy slag removal; The weld joint appearance is beautiful. _____________________________ I I Purpose:1I is used for welding of important structures of low carbon steel and low-alloy steel of corresponding strength, such as steel for shipbuilding Pu爀瀀ose:1I is used for welding of carbon steel and low-alloy structures.such as (Q235 series Grades A, B, D and E), boilers, bridges.pressure vessels and other welding of ships, vehicles and mechanical structures of 16Mn, etc. 1 structures subjected to dynamic loads under low temperature conditions. _____________________________ J _____________________________ I Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn Mn C Si s p Ni Cr Mo V C Si s p Ni Cr Mo V Test item Test item Guarantee Guarantee �0.㐀怀 �0.0㌀㔀 �0.㜀 �0. 15 �0.20 �1.㈀ �1. �0.㈀ �0.氀氀 �0. �0. 堀꼀 �0.20 �0.氀氀 �0.䌀䔀 �o. 0㌀㔀 �1.25 �o. 䤀挀 �-0㌀㔀 value value Measured Measured 0.068 0.95 0. 26 0.007 0.018 0.37 0.030 0.002 0.012 0.087 0. 65 0.25 0.014 0.024 0.032 0.032 0.005 0.015 value value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) KV2(J) Rm (MPa) ReL(MPa) A(%) Rm (MPa) ReL(MPa) A(%) Test item Test item 0뀀䌀 �430 �20 -40뀀䌀 �490 �400 �16 - �27 �330 Guarantee value Guarantee value 530 450 29 187 530 435 25 69 Measured value Measured value X-ray radiographic inspection requirements: Level II X-ray radiographic inspection requirements: Level I + Reference current (DC ) Reference current (AC.DC) welding rod Welding rod 䌀䐀2. 5 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀2. 5 diameter· (mm) diameter (mm) 60~100 80~140 110~210 70~90 90~130 160~210 210~250 Welding current (A) Welding current (A) Welding position Welding position Precautions: Precautions: ° 1.The rust, oil stain, water and other impurities of the 1 Welding rods must be baked at 350 C for 1 h before weldment must be. welding and they shall be baked immediately before use. 2.removed before welding. 2.The rust, oil stain, water and other impurities of the 3Welding rods that have been stored for a very long weldment must beremoved before welding. period shall be baked for 1h at 180-200"C before welding. 3. It is advisable to select the single pass welding method, avoiding swing 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 3 - - - - - - 22 - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - 2

J501Fe15 J502 Conform to GB/I 511㜀⸀ E5003 Conform to GB/I 511㜀⸀ E5024 AWS A5.1 E7024 ISO 2560-B-E 49 03 A J501Fe18 ISO 2560-B-E 49 24 A lnstructions:J501Fe15 and J501 Fe18 are high-efficient carbon steel welding rods 1 lnst爀甀ctions:J502 is carbon steel welding rod covered with titaniumcalcium coating. It covered with iron-powder titanium oxide coating. The deposition efficiency is about I can be used under AC and DC and all-position welding is possible. It is characterized 150% and 180% respectively. They can be used under AC and DC and are suitable for 1 by excellent welding performance and mechanical properties, stable arc, low spatter fillet welding in the flat position, downward welding and flat fillet welding. They are and easy slag removal;The weld joint appearance is beautiful. characterized by stable arc, low spatter, easy slag removal and beautiful weld joint I ------------------------------ a e ra c 1 _ � � � 㨀开: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Purpose: It is mainly used for welding of low-alloy steel structures with tensile strength 1 2 Purpose:They are used for welding of carbon steel and low-alloy structures, such as grade of 490N / mm , such as welding of screwthreaded steel used in construction 1 welding of ships, rolling stock and boilers of Grades A,B and D steel, 16Mn, etc. and other structural steel of 16Mn, etc. _____________________________ I Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn C Mn Si s p Ni Cr Mo V C Si s p Ni Cr Mo V Test item Test item Guarantee Guarantee �0.15 �0.氀氀 �0.氀氀 �0. �0.氀氀 �0.氀氀 �0. �0.㌀攀 �0.0㌀㔀 �0.㐀怀 �0.㌀攀 �0.㤀 �1.25 �1.25 �0.15 �o. 㤀 �0.20 �0.㈀ value value Measured Measured 0. 081 0.90 0.48 0.010 0.023 0.032 0.030 0.005 0.014 0. 10 0. 76 0.27 0.015 0.022 0.025 0.036 0.010 0.008 value value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) KV2(J) Test item ReL(MPa) Rm (MPa) ReL(MPa) A(%) Rm (MPa) A(%) Test item 0뀀䌀 0뀀䌀 Guarantee value �490 �490 �400 �16 �47 �400 �20 �47 Guarantee value Measured value 540 465 29 79 530 435 24 96 Measured value X-ray radiographic inspection requirements: Level II X-ray radiographic inspection requirements: Level II Reference current (AC.DC) Reference current (AC.DC) Welding rod Welding rod 琀ꄀ2. 5 琀ꄀ2. 5 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter (mm) diameter'(mm) 90~130 130~160 140~200 160~220 60~100 80~140 140~220 180~240 Welding current (A) Welding current (A) Welding position Welding position Precautions: 1.The rust, oil stain, water and other impurities of the weldment must be removed before welding. 2Welding rods that have been stored for a very long ° period shall be baked for 1h at 180-200 C before welding. Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 25 24 - - - - - - - - - - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd

J506R J506 Conform to GB/T511㜀⸀ E5016 Con orm to NB/I 4㜀⸀018 E5016 AWS A5.1 E7016 GB/T 5117 E5016 (J48•56) ISO 2560-B-E 49 16 A AWS A5.1 E7016 ISO 2560-B-E 49 16 A lnst_爀甀ctions:J506 is carbon steel welding rod covered with lowhydrogen potassium lnst爀甀ctions:J506R is carbon steel welding rod covered with lowhydrogen potassium 1 coating. It can be used under AC and DC and allposition welding is possible. It is coating that is exclusive for pressure vessels. It can be used under AC and DC and 1 1 characterized by good welding performance, stable arc, low spatter and easy slag allows all-position welding. It is characterized by good welding performance, stable arc, 1 removal. Its deposited metal has excellent mechanical properties and crack resistance, low spatter and easy slag removal. Its deposited metal has good mechanical properties and its low temperature impact toughness is good. 1 and crack resistance, and its low temperature impact toughness is good. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1 _____________________________ J Purpose:lt is used for welding of medium-carbon steel and low-alloy steel structures, Pu爀瀀ose:lt is used for welding of medium-carbon steel and low-alloy steel such_ as 16M_n, 09Mn2S1 and Grades A, B, D and E steel for shipbuilding, as well as structures such as pressure vessels and pressure-bearing pipes. welding of thick plates and carbon steelstructures with poor weldability. Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn C Si s p Ni Cr Mo V Test item C Mn Si s p Ni Cr Mo V Test item Guarantee Guarantee �0. 㜀㔀 �0.15 �.015 �0.㈀攀 �0.帀쌀 �1.昀케 �O. 氀氀 �0.20 �0.氀氀 �0.15 �0.0㌀㔀 �1.昀케 �0.氀氀 �0.娀氀 �0.氀氀 �0. �0.75 �o. 0㌀㔀 value value Measured Measured 0.078 0.96 0. 54 0.007 0.013 0.008 0.028 0.007 0.004 0.080 1. 05 0.51 0.012 0.020 0.012 0.030 0.007 0.016 value value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) KV2(J) Test item Rm (MPa) ReL(MPa) A(%) Rm (MPa) ReL(MPa) A(%) Test item 뀀䌀 -20 -30뀀䌀 -30뀀䌀 Guarantee value �490 �27 �400 �20 �47 �400 �22 �54 Guarantee value 490~610 Measured value 545 440 32 175 169 540 440 32 170 Measured value Water content of the coating: 㨀㔀0.35% X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + + Reference current (AC.DC ) Reference current (AC.DC ) Welding od Welding rod / 琀ꄀ2. 5 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 1) diameter mm diameter'< mm) 60~100 80~140 110~210 160~230 90~130 140~180 180~230 Welding current (A) Welding current (A) Welding position Welding position Precautions: ° Precautions: 1 Welding rods must be baked at 350 C for 1 h before 1Welding rods must be baked at 350'C for 1h before welding and they shall be baked immediately before use. welding and they shall be baked immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The rust, oil stain, water and other impurities of the weldment must be removed before welding. weldment must be removed before welding. 3Short arc operation is required for welding, and string 3Short arc and string bead are preferred for welding. bead is preferred. 2 - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,䰀氀d - - - - - - - - - - - - 7 - - - 6 - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - 2

JQ•J506D J506Fe Con orm to GB/T 511㜀⸀ E5018 Conform to GB/T511㜀⸀ E5016 -䤀焀脀頀焀簀瘀簀焀鴀瘀蜀였저蠀픀혀椀欀---- AWS AS.1 E7016 AWS AS.1 E7018 ISO 2560-B-E 49 16 A ISO 2560-B-E 49 18 A lnst爀甀ctions:JQ.J506D is special carbon steel welding rod for backing welding covered lnst爀甀ctions:J506Fe is carbon steel welding rod covered with iron powder with low-hydrogen potassium coating. This model of welding rods has the feature that the I low-hydrogen potassium coating, and it can be used under AC and DC. Since the arc has certain blowing force. In addition, when backing welding is performed, adopt 1 coating contains iron powder, the deposition efficiency can be improved. Arc is stable, single-side welding with back formation. Meanwhile, arc is stable, slag removal is easy spatter is low, slag removal is easy,process performance is good, the deposited metal and the weld joint generated on the back side is beautiful, which can avoid root chipping 1 has good mechanicalproperties, and all-position welding is possible. and sealing run, beneficial to improving work efficiency,but it is not suitable for multi-layer 1 welding. Pu爀瀀ose:lt is used for welding of carbon steel and low-alloy steel structures, such as : Pu爀瀀ose: It is exclusively used for backing welding of the groove of carbon steel and 1 16Mn. _____________________________ I low-alloy steel structures, such as 16Mn, 09Mn2Si and Grades A, B, D, and E steel used 1 for shipbuilding. Chemical composition of deposited metal ( % ) ________________________ 1 Chemical composition of deposited metal ( % ) Mn C Si s p Ni Cr Mo V Test item Mn C Si s p Ni Cr Mo V Test item Guarantee �0.0㌀㔀 �0.15 �1.昀케 �0. 堀꼀 �O. 氀氀 �0.20 �0.氀氀 �0.䌀䔀 �-0㌀㔀 value Guarantee �0.0㌀㔀 �0.15 �0.75 �1.昀케 �0.氀氀 �0.娀氀 �0.氀氀 �0. �o. 0㌀㔀 Measured value 0.077 1. 07 0. 54 0.005 0.014 0. 011 0.028 0.007 0.016 value Measured 0.072 0.93 0.43 0.009 0.017 0.025 0.028 0.006 0.016 value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) KV2(J) Rm (MPa) ReL(MPa) A(%) Test item Rm (MPa) ReL(MPa) A(%) Test item -30뀀䌀 �490 �400 �20 -30뀀䌀 �27 Guarantee value �400 �20 �490 �27 Guarantee value 550 455 32 156 Measured value 530 435 26 90 Measured value X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + Reference current (backing welding)(DC㈀㨀) Reference current (AC.DC ) Welding rod Welding rod 䌀䐀2. 5 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀 2. 5 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter(mm) diameter (mm) 50~80 70~100 100~160 60~100 80~140 110~210 160~230 Welding current (A) Welding current (A) Welding position Welding position Precautions: Precautions: 1 Welding rods must be baked at 350 °C for 1 h before 1Welding rods must be baked at 350'C for 1h before welding and they shall be baked immediately before use. welding and they shall be baked immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The rust, oil stain, water and other impurities of the weldment must be removed before welding. weldment must be removed before welding. 3Short arc operation is required for welding, without 3Short arc operation is required for welding, and string swing, and string bead is preferred. bead is preferred. 2 - - - - - - 8 - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd 吀椀anjin Golden Bridge Welding Materials Group Co.,䰀氀d - - - - - - - - - - - - 9 - - - - 2

J506Fe16 J506Fe-1 Conform to GB吀鐀 5117 E5018-1 Con orm to GBIT 511㜀⸀ E5028 AWS A5.1 E7018-1 AWS A5.1 E7028 J506Fe18 ISO 2560-B-E 49 18-1 A ISO 2560-B-E 49 28 A lnst爀甀ctions:J506Fe-1 is carbon steel welding rod covered with iron powder lnst爀甀ctions:J506Fe16 and J506Fe18 are high-efficiency carbon steel welding rods low-hydrogen potassium coating. It can be used under AC and DC and all-position covered with iron powder low-hydrogen potassium coating, of which, deposition welding is possible. Due to addition of a large number of alloying elements, it has good efficiency can reach about 160% and 180% respectively. In addition, they can be used plasticity and low temperature impact toughness, together with good welding under AC and DC. They are characterized by deposited metal with good mechanical 1 1 performance, stable arc, low spatter, easy slag removal and high deposition efficiency. properties, stable arc, low spatter, easy slag removal and beautiful weld joint appearancef They are suitable for downward welding and flat fillet welding. 1 Purpose:lt is applicable to welding of carbon steel and low-alloy steel structures such 1 as offshore oil platforms and ocean-going vessels. Pu爀瀀ose:They are used for downward welding and flat fillet welding of carbon steel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - _I 1 and low-alloy steel structures, such as 16Mn, 09Mn2Si and Grades A, B, D, and E steel used for shipbuilding. Chemical composition of deposited metal ( % ) _____________________________ I Chemical composition of deposited metal ( % ) Mn C Si s p Ni Cr Mo V Test item Mn C Si s p Ni Cr Mo V Test item Guarantee �0.0㌀㔀 �0.㤀 �0.15 �1.昀케 �0.氀氀 �0.娀氀 �0.氀氀 �0. �o. 0㌀㔀 value Guarantee �0.㤀 �0.15 �1.昀케 �O. 氀氀 �0.20 �0.氀氀 �0.䌀䔀 �o. 0㌀㔀 �-0㌀㔀 value Measured 0.069 1. 20 0. 36 0.006 0.016 0.26 0. 031 0.008 0.017 value Measured 0.077 1. 03 0.005 0.014 0. 011 0.028 0.007 0.016 0.35 value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) KV2(J) Rm (MPa) ReL(MPa) A(%) Rm (MPa) ReL(MPa) A(%) Test item Test item 뀀䌀 뀀䌀 뀀䌀 -20 -40 -45 �400 �20 �400 �20 �490 �490 �27 �27 �47 Guarantee value Guarantee value 440 33 190 184 430 26 189 535 535 Measured value Measured value X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level II + + Reference current (AC.DC ) Reference current (AC.DC ) Welding r6d Welding rod 琀ꄀ2. 5 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀4. 0 䌀䐀5. 0 diameter' (mm) diameter· (mm) 60~100 90~140 160~210 180~240 180~240 210~280 Welding current (A) Welding current (A) Welding position Welding position Precautions: Precautions: ° ° 1 .Welding rods must be baked at 350 C for 1 h before 1.Welding rods must be baked at 350 C for 1h before welding and they shall be baked immediately before use. welding and they shall be baked immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The rust, oil stain, water and other impurities of the weldment must be removed before welding. weldment must beremoved before welding. 3Short arc operation is required for welding and swing 3Short arc operation is required for welding, and string shall be avoided. bead is preferred. 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 31 30 - - - - - - - - - - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd

J507R J507 Conform to GB/I 511㜀⸀ E5015 ⸀贀 _ _,Ⰰ堀con!!!for-"'-mⴀ䤀 to蜀鴀N尀娀BⰀ謀r爀⸀똁ᜀ4 㜀⸀⸀堀0堀樀1堀謀8E∀∀S㰀樀01 5 ___ _ ∀䤀 贀堀Ⰰ开 AWSA5.1 E7015 GB/T 5117 E5015 (J48•57) ISO 2560-B-E 49 15 A AWS A5.1 E7015 ISO 2560-B-E 49 15 A lnstructions:J507 is carbon steel welding rod covered with low hydrogen sodium coating. Adopt DCRP and all-position welding is possible. It is characterized by good lnstructions:J507R is carbon steel welding rod covered with lowhydrogen sodium 1 welding performance, stable arc, low spatter and easy slag removal. Its deposited metal coating exclusive for pressure vessels. Adopt DCRP and all-position welding is possible. 1 has excellent mechanical properties and crack resistance, and its low temperature In addition, It is characterized by excellent welding performance, stable arc, low spatter, 1 impact toughness is good. easy slag removal.and its deposited metal has excellent mechanical properties and crack resistance, as well as good low temperature impact toughness. 1 Purpose: It is used for welding of important medium-carbon steel and low-alloy steel ------------------------------ structures (pressure, dynamic load), such as 16Mn, 09Mn2Si, 09Mn2V and Grades A, B, Purpose:lt is used for welding of medium-carbon steel and low-alloy steel structures 1 1 D and E steel for shipbuilding, as well as welding of thick plates and carbon steel such as pressure vessels and pressure-bearing pipes. structures with poorweldability. -----------------------------' _____________________________ J Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) C Mn Si s p Ni Cr Mo V Test item Mn C Si s p Ni Cr Mo V Test item Guarantee �0.㈀攀 �0.15 �0.75 �1. 昀케 �0.氀氀 �0.娀氀 �0.氀氀 �o. 015 �o.m Guarantee value �0.0㌀㔀 �0.㌀攀 �0.15 �1. 昀케 �0.氀氀 �0.20 �0.氀氀 �0. �-㤀 value Measured 0.070 1. 20 0. 62 0.008 0.012 0.010 0.032 0.008 0.004 Measured value 0.087 1. 12 0.58 0.012 0. 021 0. 011 0.028 0.007 0.016 value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) KV2(J) Test item ReL(MPa) Rm (MPa) A(%) Rm (MPa) ReL(MPa) A(%) Test item 뀀䌀 -20 -30뀀䌀 -30뀀䌀 Guarantee value �490 �400 �20 �47 �27 490~610 �400 �22 �54 Guarantee value Measured value 560 450 32 150 142 545 450 32 150 Measured value Water content of the coating: 㨀㔀0.35% X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + + Reference current (DC ) Reference current (DC ) we1amg roa Welding rod 䌀䐀2. 5 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter (mm) diameter' (mm) Welding current (A) 60~100 80~140 110~210 160~230 90~130 140~180 180~230 Welding current (A) Welding position Welding position Precautions: ° Precautions: ° 1 Welding rods must be baked at 350 C for 1 h before 1. Welding rods must be baked at 350 C for 1 h before welding and theyshall be baked immediately before use. welding and they shall be baked immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The rust, oil stain, water and other impurities of the weldment must beremoved before welding. weldment must be removed before welding. 3Short arc and string bead are preferred for welding. 3Short arc operation is required for welding, and string bead is preferred. 32 - - - - - - - - - - - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd Tianjin Golden Bridge Welding Materials Group Co.,Lld - - - - - - - - - - - - 33

J507X Conform to GB/⸀吀 511㜀⸀ E5028 Conform to GB/T 511㜀⸀ E5015 J507Fe16 AWS A5.1 E7028 AWSA5.1 E7015 ISO 2560-B-E 49 28 A ISO 2560-B-E 49 15 A lnstructions:J507Fe16 is high-efficiency carbon steel welding rod covered with iron powder low-hydrogen sodium coating. The deposition efficiency is lnstructions:J507X is special carbon steel welding rod covered with low-hydrogen about 160%. Adopt DCRP and it is suitable for downward welding and flat sodium coating for vertical downward fillet weld. Adopt DCRP and it has good welding fillet welding. They are characterized by deposited metal with good performance. Vertical downward welding is dominant. During welding, it is required to mechanical properties, stable arc, low spatter, easy slag removal and move from top to bottom.The arc is stable, slag removal is easy, weld ripples are beautiful weld joint appearance. uniform and weld joint appearance is beautiful. Purpose:lt is used for downward welding and flat fillet welding of carbon steel and Pu爀瀀ose:lt is applicable to welding of vertical downward fillet weld of carbon steel low-alloy steel structures, such as 16Mn, 09Mn2Si, 09Mn2V and Grades A, B, D, and and low-alloy steel structures. E steel for shipbuilding. - - - - ⸀䨀 Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn C Si s p Ni Cr Mo V Test item Mn C Si s p Ni Cr Mo V Test item Guarantee Guarantee �0.㤀 �0.15 �1.昀케 �O. 氀氀 �0.20 �0.氀氀 �0.䌀䔀 �o. 0㌀㔀 �-0㌀㔀 �0.0㌀㔀 �0.㤀 �0.15 �1.昀케 �0.氀氀 �0.娀氀 �0.氀氀 �0. �o. 0㌀㔀 value value Measured Measured 0.067 0. 70 0.46 0.012 0.013 0.27 0.028 0.007 0.016 0.086 1. 13 0.55 0.012 0. 021 0. 011 0.028 0.007 0.016 value value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2 J KV2 J ) ) ( ( Rm (MPa) ReL(MPa) A(%) Test item Rm (MPa) ReL(MPa) A(%) Test item 뀀䌀 뀀䌀 -20 -30 �400 �20 Guarantee value �400 �20 �27 �27 �490 �490 Guarantee value 560 450 30 147 560 432 30 112 Measured value Measured value The water content of the coating is 㨀㔀0.60% X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level II + + Reference current (DC ) Reference current (DC ) 瘀瘀eldmg rod Welding rod 䌀䐀4. 0 䌀䐀5. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter·(mm) diameter· (mm) 180~240 210~280 80~130 110~180 160~210 Welding current (A) Welding current (A) Welding position Welding position Precautions: ° Precautions: 1 .Welding rods must be baked at 350 C for 1 h before ° 1.Welding rods must be baked at 350 C for 1h before welding and they shall be baked immediately before use. welding and they shall be baked immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The rust, oil stain, water and other impurities of the weldment must be removed before welding. weldment must be removed before welding. 3Short arc operation is required for welding, dragging 3Short arc operation is required for welding and swing downward in a straight way, generally not allowing swing shall be avoided. or allowing slight swing 34 - - - - - - - - - - - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 35

Conform to GB/⸀吀 511㜀⸀ E5016-N1 倀ⴀ Conform to GB/I 511㜀⸀ E5015-N1 倀ⴀ J507RH J506RH AWS A5.5 E7016-G AWS A5.5 E7015-G ISO 2560-B-E 49 16-N1 P ISO 2560-B-E 49 15-G P lnstructions:J506RH is high toughness ultra-low-hydrogen low-alloy steel lnstructions:J507RH is high toughness ultra-low-hydrogen low-alloy steel welding rod I welding rod covered with low-hydrogen potassium coating, which can be 1 covered with low-hydrogen sodium coating, and it adopts DCRP. It is characterized by used under AC and DC. It is characterized by good welding process, stable good welding process, stable arc, easy slag removal, and its deposited metal has arc, easy slag removal, and its deposited metal has excellent plasticity, excellent plasticity,toughness and crack resistance. All-position welding is possible. toughness and crack resistance. All-position welding is possible. Pu爀瀀ose:lt is applicable to welding of important structures of low-alloy steel, such as Purpose:lt is applicable to welding of important structures of low-alloy steel, such as 1 E36, DE36 and A537. Such as offshore platforms, ships and pressure vessels. E36, DE36 and A537. Such as offshore platforms, ships and pressure vessels. -----------------------------� Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn C Si s p Ni Mo V Test item Mn C Si s p Ni Mo V Test item 0. 騀錀 o.渀ⴀ Guarantee 0. 騀錀 o.渀ⴀ �o. ㌀㔀 �0.12 �a.cm �a.cm �O.䈀贀 �o. 㤀 Guarantee �0.12 �a.挀洀 �a.挀洀 �0.㌀㔀 �O.䈀贀 �O. 砀鄀 1. 1.椀툀 value 1.椀툀 1. value Measured 0.065 1. 13 0. 28 0.006 0.015 0.65 0.009 0.005 Measured 0.073 1. 15 0.53 0.006 0.015 0.55 0.010 0.005 value value Mechanical properties of deposited metal Mechanical properties of deposited metal KV2(J) ReLIRp0.2 KV2(J) ReLIRp0.2 Rm (MPa) A(%) Test item Test item Rm (MPa) A(%) (MPa) -40뀀䌀 (MPa) -40뀀䌀 �20 �490 �390 �27 Guarantee value Guarantee value �20 �27 �490 �390 550 450 30 138 Measured value Measured value 550 445 29 130 Diffusible hydrogen content of the deposited metal: �5.0ml/1 00g Diffusible hydrogen content of the deposited metal: �5.0ml/100g (thermal conductivity method or mercury method) (thermal conductivity method or mercury method) X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + + Reference current (DC ) Reference current (AC.DC ) 瘀瘀eldmg rod Welding rod 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter·(mm) diameter· (mm) 80~120 130~180 170~240 80~120 130~180 170~240 Welding current (A) Welding current (A) Welding position Welding position Precautions: Precautions: 1.The welding rods must be baked at 400 'C for 1 h before 1 The welding rods must be baked at 400'C for 1 h before ° welding, and then placed in a 100-150 'C thermostat. They welding, and then placed in a 100-150 C thermostat. They shall be taken out immediately before use. shall be baked immediately before use. 2.The rust, oil stain, water and other impurities of the 2. The rust, oil stain, water and other impurities of the weldment must be removed before welding. weldment must be removed before welding. 3.Short arc operation is required for welding, and string 3. Short arc operation is required for welding, and string bead is preferred. bead is preferred. 36 - - - - - - - - - - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 37

Conform to GB/⸀吀 511㜀⸀ E5015-G 倀ⴀ Conform to GB/T 511㜀⸀ E5015-G 倀ⴀ J507Q J507Ni AWS A5.5 E7015-G AWS A5.5 E7015-G ISO 2560-B-E 49 15-G P ISO 2560-B-E 49 15-G P lnstructions:J507Ni is low-alloy steel welding rod covered with lowhydrogen lnstructions:J507Q is special low-alloy steel welding rod covered with low-hydrogen sodium coating. Adopt DCRP and all-position welding is possible. It has low sodium coating for ultra-low-hydrogen high-toughness bridge steel. Adopt DCRP. It has 1 diffused hydrogen content and excellent low temperature impact toughness. good welding performance and allows all-position welding, and the weld metal is 1 characterized by excellent plasticity, toughness and crack resistance. 1 Purpose:lt is applicable to welding of medium-carbon steel and lowtemperature steel Purpose: It is used for welding of low-alloy bridge steel structures. 1 pressure vessels, such as 16MnDR. -----------------------------� Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn Mn C Si s p Ni C Si s p Ni Test item Test item Guarantee 1. 崀 1. 崀 Guarantee �O. 0㌀㔀 �0.㌀攀 �0.10 �1.昀케 �0.㤀 �0.10 �1.昀케 �0.㜀 �0.㈀怀 �o. cm value 2 2 value Measured Measured 0. 071 1. 05 0.50 0.006 0.014 1. 30 0.065 1. 0 0.38 0.008 0.016 1. 40 value value ° Mechanical properties of deposited metal (620 C x 1 h heat treatment) Mechanical properties of deposited metal KV2(J) KV2(J) ReLIRp0.2 ReLIRp0.2 Test item Rm (MPa) A(%) Rm (MPa) A(%) Test item (MPa) (MPa) -40뀀䌀 -40뀀䌀 Guarantee value �400 �20 �22 �27 �490 �490 �390 �47 Guarantee value 575 465 30 167 Measured value 550 460 30 120 Measured value X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + + Reference current (DC ) Reference current (DC ) Welding rod welding rod 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter·(mm) diameter·(mm) 90~120 120~180 160~210 80~120 130~180 170~240 Welding current (A) Welding current (A) Welding position Welding position Precautions: ° Precautions: 1.The welding rods must be baked at 350-400 C for 1 h ° ° 1 .Welding rods must be baked at 350 C for 1 h before before welding.and then placed in a 100-150 C thermostat. welding and they shall be baked immediately before use. They shall be taken out immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The rust, oil stain, water and other impurities of the weldment must be removed before welding. weldment must be removed before welding. 3Short arc operation is required for welding, and string bead is preferred. Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 39 38 - - - - - - - - - - - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd

J507FeNi J507CrNi Conform to GB吀鐀 511㜀⸀ E5018-G e Conform to GB/I 511㜀⸀ E5015-G e AWSA5.5 E7018-G AWSA5.5 E7015-G I SO 2560-B-E 49 18-G P ISO 2560-B-E 49 15-G P I lnstructions:J507CrNi is low-alloy steel welding rod covered with lowhydrogen sodium 1 lnstructions:J507FeNi is low-alloy steel welding rod covered with ironpowder coating which can resist seawater corrosion, with good plasticity, low temperature low-hydrogen coating. Adopt DCRP and all-position welding is possible. It has low toughness and seawater corrosion resistance.Adopt DCRP and all-position welding is diffused hydrogen content and excellent low temperature impact toughness. possible. Purpose:lt is applicable to welding of medium-carbon steel and lowtemperature Purpose:lt is applicable to welding of important marine structures with seawater steel pressure vessels, such as 16MnDR corrosion resistance of Q235, 16Mn and Cr-Al systems. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - _I _____________________________ I Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn Mn C Si s p Ni C Si s p Cr Ni Cu Test item Test item O.케錀 0. 开 0. 开 Guarantee Guarantee 1. 崀2. �0.0㌀㔀 �0.0㌀㔀 �0.0㌀㔀 �0.㌀攀 �0.㤀 �O. 砀鄀 �0.10 �1. 昀케 �0.10 �1. 昀케 0.㔀 0.㔀 value 0. 堀氀 value Measured Measured 0.070 1. 12 0.25 0.006 0.016 1. 40 0.065 0.95 0. 33 0.006 0.016 0. 70 0.42 0.30 value value ° ° Mechanical properties of deposited metal (620 C x 1 h heat treatment) Mechanical properties of deposited metal (620 C x 1 h heat treatment) KV2(J) KV2(J) ReLIRp0.2 ReLIRp0.2 Test item Test item Rm (MPa) A(%) Rm (MPa) A(%) (MPa) (MPa) -30뀀䌀 -40뀀䌀 Guarantee value Guarantee value �400 �20 �400 �20 �490 �490 �27 �27 575 460 30 140 Measured value 565 465 26 136 Measured value X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + + Reference current (DC ) Reference current (DC ) Welding rod Welding rod 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diamete爀∀(mm) diameter·(mm) 90~120 120~180 160~210 90~120 140~180 170~210 Welding current (A) Welding current (A) Welding position Welding position Precautions: Precautions: ° ° 1.The welding rods must be baked for 1h at about 350 C 1.Welding rods must be baked at 350 C for 1h before before use and they shall be taken out immediately before use. welding and they shall be baked immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The rust, oil stain, water and other impurities of the weldment must be removed before welding. weldment must be removed before welding. 3Short arc operation is adopted for welding. Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 41 40 - - - - - - - - - - - • Tianjin Golden Bridge Welding Materials Group Co.,Ltd

J507NiTiB J507Mo Con orm to GBIT 511㜀⸀ E5015-G 倀ⴀ Conform to GB/T 5117 E5015-G 倀ⴀ AWS A5.5 E7015-G AWS A5.5 E7015-G ISO 2560-B-E 49 15-G P ISO 2560-B-E-49 15-G P lnstructions:J507NiTiB is high-toughness low-alloy steel welding rod covered with lnstructions:J507Mo is low-alloy steel welding rod covered with lowhydrogen sodium 1 low-hydrogen sodium coating. Its deposited metal contains Ni-Ti-B elements, which coating, resisting H2S corrosion. Adopt DCRP and allposition welding is possible. Its makes it have excellent impact toughness at low temperature. The welding rod has good 1 deposited metal has good corrosion resistance and crack resistance, as well as good process performance. Adopt DCRP and all-position welding is possible. 1 welding performance. ------------------------------ 1 Purpose:lt is applied to welding of ships, boilers, pressure vessels, mining engineering Purpose:lt is applicable to welding of corrosion resistant steel containing 1 machinery, offshore engineering structures and other important structures. elements such as Mo, V or low Al. Such as welding of 12CrMoVAI and steel ° - - - - - - - - - - - - - - - - - - - - - - - - - - - - - _I that can resist high temperature of 400 C and S and H2S corrosion. -----------------------------' Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn C Si s p Ni Ti B C Mn Si s p Mo V Test item Test item 0. 㸀餀 0.010- 0. 1- 0. 㸀餀 Guarantee Guarantee �1.昀케 �0. 堀꼀 �1.昀케 �0.娀氀 �0.㌀攀 �0.㌀攀 �0.㤀 �o. 0㌀㔀 �o. 0㌀㔀 �0.10 �0.10 0. 0. 礀爀 0. 搀 0. value value Measured Measured 0.056 1. 14 0.26 0.005 0.014 0.56 0.027 0.003 0.054 0. 78 0.27 0.011 0.018 0.46 0. 11 value value ° ° Mechanical properties of deposited metal (620 C x 1 h heat treatment) Mechanical properties of deposited metal (620 C x 1 h heat treatment) KV2(J) KV2(J) ReLIRp0.2 ReLIRp0.2 Rm (MPa) A(%) Rm (MPa) A(%) Test item Test item (MPa) (MPa) -40뀀䌀 -30뀀䌀 �400 �20 �400 �20 �490 �27 �490 �27 Guarantee value Guarantee value 545 455 30 155 560 460 30 132 Measured value Measured value X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + + Reference current (DC ) Reference current (DC ) 瘀瘀e1amg roa 瘀瘀eldmg rod 䌀䐀2. 5 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀S. 0 䌀䐀3. 2 䌀䐀4. 0 䌀䐀S. 0 䌀䐀2. 5 diameter (mm) diameter (mm) Welding current (A) Welding current (A) 60~100 80~130 120~190 160~230 60~90 90~130 110~180 160~210 Welding position Welding position Precautions: Precautions: ° ° 1 Welding rods must be baked at 400 C for 1 h before 1 Welding rods must be baked at 350 C for 1 h before welding and they shall be baked immediately before use. welding and they shall be baked immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The rust, oil stain, water and other impurities of the weldment must be removed before welding. weldment must be removed before welding. 3Short arc operation is adopted for welding, and string 3S hort arc operation is required for welding, and string bead is preferred. bead is preferred. Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 43 42 - - - - - - - - - - - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd

J507MoW J556 Conform to GB/T5117 E5015-G 倀ⴀ Conform to GBf吀⸀ 5117 E5516-G 倀ⴀ AWS A5.5 E7015-G AWS A5.5 E8016-G I SO 2560-B-E 49 15-G P I SO 2560-B-E 55 16-G P 1 lnstructions:J507MoW is low-alloy steel welding rod covered with lowhydrogen lnstructions:J556 is low-alloy steel welding rod covered with lowhydrogen potassium sodium coating, resisting H, N and NH3 corrosion. Adopt DCRP and all-position coating and it can be used under AC and DC. Allposition welding is possible. ------------------------------ welding is possible. Its deposited metal has good corrosion resistance and welding performance. Purpose:lt is applicable to welding of medium-carbon steel and lowalloy steel Purpose:lt is used for welding of low-alloy steel containing such elements as Mo, W, structures, such as 15Mn Ti and 15MnV. Nb and V and resisting H, N and NH3 corrosion under high temperature and high pressure, such as welding of 1 0MoWVNb resisting hydrogen corrosion under high 1 Chemical composition of deposited metal ( % ) temperature and high pressure or steel resisting H, N and NH3 corrosion under high temperature and high pressure. Mn C Si s p -----------------------------� Test item Chemical composition of deposited metal ( % ) Guarantee �0.12 �1.昀케 �-cm �o. cm �0.㤀 value C Mn Si s p Mo w V Nb Test item Measured 0.073 1. 38 0. 25 0.006 0.015 value 0. 㔀 - 0.㔀 - Guarantee �0.10 �0. �0.㈀怀 �0.㈀怀 �0.20 �0.12 �-㔀 0. 㤀 0. 㤀 value ° Mechanical properties of deposited metal (620 C x 1 h heat treatment) Measured 0.052 0. 78 0.27 0.006 0.012 0.53 0.54 0. 11 0.050 value KV2(J) ReLIRp0.2 Mechanical properties of deposited metal Test item Rm (MPa) A(%) ° (MPa) (740 C x 2.5h heat treatment) Guarantee value �550 �460 �17 -30뀀䌀 �27 KV2(J) ReLIRp0.2 Test item Rm (MPa) A(%) (MPa) 0뀀䌀 Measured value 575 485 26 136 Guarantee value �400 �20 �490 �27 X-ray radiographic inspection requirements: Level I Measured value 650 560 23 60 + Reference current (AC.DC ) X-ray radiographic inspection requirements: Level I Welding rod + 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter (mm) Reference current (DC ) 80~140 110~210 160~230 Welding od Welding current (A) 䌀䐀2. 5 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 / i l diameter mm Welding position Precautions: 60~90 90~120 110~180 160~210 Welding current (A) ° 1 .Welding rods must be baked at 350 C for 1 h before Precautions: welding and they shall be baked immediately before use. ° Welding position 1 .Welding rods must be baked at 350 C for 1 h before 2.The rust, oil stain, water and other impurities of the welding and they shall be baked immediately before use. weldment must be removed before welding. 2.The rust, oil stain, water and other impurities of the 3Short arc operation is required for welding, and string weldment must be removed before welding. bead is preferred. 3Short arc operation is required for welding, and string bead is preferred. 4. The medium-thickness weldment shall be preheated at ° about 150 C before welding, and tempered at ° 740 C after welding. 㐀㐀 - - - - - - - - - - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd Tianjin Golden Bridge Welding Materials Group Co.,Lld - - - - - - - - - - - - 㐀㔀

J556RH J557 Con orm to GBIT 511㜀⸀ E5516-N1 倀ⴀ Conform to GB/T 511㜀⸀ E5515-G 倀ⴀ AWS A5.5 E8016-G AWSA5.5 E8015-G ISO 2560-B-E 55 16-N1 P ISO 2560-B-E 55 15-G P lnstructions:J556RH is high-toughness welding rod covered with ultralow hydrogen potassium coating. Its deposited metal has excellent plasticity, lnstructions:J557 is low-alloy steel welding rod covered with lowhydrogen sodium toughness and crack resistance. It can be used under AC and DC, but it is coating and it adopts DCRP. All-position welding is possible. ------------------------------ recommended to adopt DCRP and all-position welding is possible. Purpose:lt is applicable to welding of medium-carbon steel and lowalloy steel Purpose:lt is applicable to important low-alloy steel structures such as pressure structures, such as 15MnTi and 15MnV. vessels, offshore production platforms and ships. -----------------------------� Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn C Si s p Test item C Mn Si s p Ni Mo V Test item Guarantee 0. 昀椀l- 0. 䤀뜀- Guarantee �0.㤀 �0.12 �1.昀케 �0.氀묀 �0.氀묀 �0.12 �o. 氀砀 �o. 㔀怀 �o. 㤀 �o.爀턀 �o. ㌀㔀 value value 1.昀케 1. Measured Measured 0.074 1. 32 0.50 0.007 0.015 0.076 1. 10 0.22 0.004 0.017 0.81 0. 15 0.005 value value ° ° Mechanical properties of deposited metal (62O C x 1 h heat treatment) Mechanical properties of deposited metal (62O C x 1 h heat treatment) KV2(J) KV2(J) ReLIRpO.2 ReLIRpO.2 Test item Rm (MPa) A(%) Test item Rm (MPa) A(%) (MPa) (MPa) -4O뀀䌀 -3O뀀䌀 �550 �460 �17 �27 Guarantee value Guarantee value �550 �460 �17 �27 590 500 28 108 Measured value Measured value 585 485 28 120 Diffusible hydrogen content of the de osited metal: 㨀匀S.0ml/1 00g p X-ray radiographic inspection requirements: Level I (thermal conductivity method or mercury method) + X-ray radiographic inspection requirements: Level I Reference current (DC ) + Reference current (AC.DC ) Welding rod 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diamete爀✀ (mm) Welding rod 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter·(mm) 80~140 110~210 160~230 Welding current (A) 80~140 130~180 170~240 Welding current (A) Welding position Precautions: ° 1 Welding rods must be baked at 350-400 C for 1 h before Welding position Precautions: ° welding and they shall be baked immediately before use. 1.The welding rods must be baked at 400 C for 1 h before ° 2.The rust, oil stain, water and other impurities of the welding, and then placed in a 100-150 C thermostat. They weldment must be removed before welding. shall be taken out immediately before use. 3Short arc operation is required for welding, and string 2.The rust, oil stain, water and other impurities of the bead is preferred. weldment must be removed before welding. 3Short arc operation is required for welding. 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 47 46 - - - - - - - - - - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd

J557R J557RH Con orm to NB/I 4㜀⸀018 E5515-G 倀ⴀ Conform to GB/I 511㜀⸀ E5515-N1 e GB/T 5117 E5515-G P AWS A5.5 E8015-G AWS A5.5 E8015-G ISO 2560-B-E 55 15-N 1 P ISO 2560-B-E 55 15-G P lnstructions:J557RH is high-toughness welding rod covered with ultra-low hydrogen lnstructions:J557R is low-alloy steel welding rod covered with low-hydrogen sodium coating. Its deposited metal has excellent plasticity.toughness and crack sodium coating exclusive for pressure-bearing equipment.Adopt DCRP and resistance. Adopt DCRP and all-position welding is possible. 1 ------------------------------ all-position welding is possible. _____________________________ J Purpose:lt is applicable to important low-alloy steel structures such as pressure Purpose:lt is applicable to welding of low-alloy steel structures of corresponding vessels, offshore production platforms and ships. strength grade for pressure vessels. -----------------------------� Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) C Mn Si s p Ni Mo V Test item 0.椀 0. ㌀紀- Guarantee Mn C Si s p �a.cm �a.cm �0.㔀怀 �0.㌀㔀 �0.12 �0.90 Test item 1. 昀케 1. value Guarantee Measured �o. 015 0.068 1. 25 0.30 0.007 0.016 0.80 0. 20 0.006 �0.㈀攀 �0.㤀 �0.12 �1. 昀케 value value Measured 0.076 1. 40 0.48 0.006 0. 011 ° value Mechanical properties of deposited metal (620 C x 1 h heat treatment) ° KV2(J) Mechanical properties of deposited metal (620 C x 1 h heat treatment) ReLIRp0.2 Test item Rm (MPa) A(%) (MPa) -40뀀䌀 KV2(J) ReLIRp0.2 Test item Rm (MPa) A(%) (MPa) Guarantee value �460 �550 �17 �27 -40뀀䌀 Measured value Guarantee value 550-670 �460 �20 600 510 28 120 �54 600 510 28 120 Measured value Diffusible hydrogen content of the deposited metal: 㨀匀5.0ml/100g (thermal conductivity method or mercury method) Water content of the coating: 㨀匀0.20% X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + + Reference current (DC ) Reference current (DC ) 瘀瘀eldmg rod 瘀瘀eldmg rod 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter (mm) diameter·(mm) Welding current (A) 80~120 130~180 170~240 80~120 130~180 170~240 Welding current (A) Precautions: Welding position Welding position Precautions: ° ° 1 .The welding rods must be baked at 350-400 C for 1.5h 1.The welding rods must be baked at 400 C for 1 h before ° ° before welding.and then placed in a 100-150 C thermostat. welding, and then placed in a 100-150 C thermostat. They shall be taken out immediately before use. They shall be taken out immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The rust, oil stain, water and other impurities of the weldment must be removed before welding. weldment must be removed before welding. 3Short arc operation is required for welding, and string 3Short arc operation is required for welding, and string bead is preferred. bead is preferred. Tianjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 49 㐀㠀 - - - - - - - - - - - - Tianjin Golden Bridge Welding Materials Group Co.,Ltd

J607 J606RH Conform to GB/T 32533 E5915-3M2 倀ⴀ Conform to GB⼀吀32533 E5916-G 倀ⴀ 尀蠀꤀需ꠀ씀伀簀簀焀䬀==娀樀帀贀글꤀눁ጀ ____ _ AWS A5.5 E9016-G AWSA5.5 E9015-D1 Equivalent to ISO 18275-B-E 5916-N1M1 P ISO 18275-B-E 59 15-3 M2 P lnstructions:J606RH is high-roughness welding rod covered with ultralow hydrogen potassium coating for 590MPa crack-free steel of pressure vessels and it can be used under AC and DC. It is characterized by good notch impact lnstructions:J607 is low-alloy high-strength welding rod covered with low-hydrogen toughness and crack resistance and allows all-position welding. sodium coating and it adopts DCRP. I ------------------------------ I ------------------------------ Purpose:lt is applied to welding of important structures, such as pressure vessels, 1 bridges, down comers of hydropower stations and marine engineering and it can be well Purpose:lt is used for welding of medium-carbon steel and low-alloy steel of 1 matched with CF60 (62) steel. corresponding strength, such as 15MnVN. I ------------------------------ _____________________________ I Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) Mn C Si s p Ni Mo Test item Mn C Si s p Mo Test item Guarantee 0.10- 0. 昀昀i- �0.㈀攀 �0.10 �1. �0. �0.㈀餀 value 0.⠀娀 1. 20 Guarantee 1. 25- O.愀ⴀ �0.12 �o. cm �o.爀턀 �O. 昀씀 value 1. 75 0.㐀㔀 Measured 0.087 1. 31 0. 23 0.006 0.017 1. 14 0. 18 value Measured 0.059 1. 38 0.47 0.006 0.014 0. 35 value ° Mechanical properties of deposited metal (620 C x 1 h heat treatment) ° Mechanical properties of deposited metal (620 C x 1 h heat treatment) KV2(J) ReLIRp0.2 Rm (MPa) A(%) Test item (MPa) -40뀀䌀 KV2(J) ReLIRp0.2 Test item Rm (MPa) A(%) (MPa) -20뀀䌀 �620 �530 �17 �47 Guarantee value Guarantee value �620 �530 �17 �27 610 21 76 590 Measured value Measured value 640 110 25 545 Diffusible hydrogen content of the deposited metal: 㨀匀5.Oml/1OOg (thermal conductivity method or mercury method) X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + + Reference current (DC ) Reference current (AC.DC ) 瘀瘀eldmg rod Welding rod 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter (mm) diameter' (mm) Welding current (A) 80~120 130~180 170~240 80~140 110~210 160~230 Welding current (A) Precautions: ° Welding position Welding position Precautions: 1Welding rods must be baked at 350 C for 1h before ° 1.The welding rods must be baked at about 400 C for 1 h welding and they shall be baked immediately before use. ° before welding, and then placed in a 100-150 C thermostat. 2.The rust, oil stain, water and other impurities of the They shall be taken out immediately before use. weldment must be removed before welding. 2.The rust, oil stain, water and other impurities of the 3Short arc operation is required for welding, and string weldment must be removed before welding. bead is preferred. 4When the weldment is relatively thick, it shall be ° preheated until temperature reaches above 150 C Then, conduct slow cooling after welding. 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 53 52 - - - - - - - - - - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd

J607Ni Conform to GB/I 32533 E6215-G e J607RH Conform to GB⼀吀32533 E5915-G 倀ⴀ 言蠀瀀꤀笀鸀簀ꌀ瘀焀ꌀ글开笀樀稀✀ⴀ䐀䐀�簀ꌀ묀뤀 ___ _ AWSA5.5 E9015-G AWSA5.5 E9015-G Equivalent to ISO 18275-B-E 59 15-N1 M1 P I SO 18275-B-E 62 15-G P lnstructions:J607RH is high-roughness welding rod covered with ultralow lnstructions:J607Ni is low-alloy high-strength steel welding rod covered with hydrogen sodium coating for 590MPa crack-free steel of pressure vessels and it low-hydrogen sodium coating and it adopts DCRP. Its deposited metal is characterized adopts DCRP. It is characterized by good notch impact toughness and crack by good notch impact toughness and crack resistance and allows all-position welding. 1 resistance and allows all-position welding. ------------------------------ I ------------------------------ 1 Purpose:lt is applied to welding of important structures, such as pressure vessels, Purpose:lt is applied to welding of structural steel of corresponding strength grade 1 bridges, down comers of hydropower stations and marine engineering and it can be well and has reheating cracking tendency, such as welding and repair welding of nuclear 1 matched with CF60 (62) steel. 1 reactor shells, boiler drums, chemical containers and storage tanks. 1 ----------------------------- 7 Chemical composition of deposited metal ( % ) Chemical composition of deposited metal ( % ) C Mn Si s p Ni Mo Test item Mn C Si s p Ni Mo Test item Guarantee 0. 昀昀i- 0.10- �0.㈀攀 �0.10 �1. �0. �0.㈀餀 Guarantee 0.10- 1. 20- value 1. 20 Q_ ⠀爀 �0.10 �1. �a.挀洀 �o. cm �- value 1.㔀 0.㐀 Measured 0. 061 1. 30 0.32 0.005 0.013 1. 15 0. 24 Measured value 0.068 1. 47 0.52 0. 011 0.015 1. 23 0. 18 value ° Mechanical properties of deposited metal (620 C x 1 h heat treatment) ° Mechanical properties of deposited metal (620 C x 1 h heat treatment) KV2(J) ReLIRp0.2 Test item Rm (MPa) A(%) KV2(J) (MPa) ReLIRp0.2 -40뀀䌀 Test item Rm (MPa) A(%) (MPa) -40뀀䌀 �17 �590 �490 Guarantee value �47 Guarantee value �620 �17 �530 �34 650 550 26 120 Measured value Measured value 660 570 26 80 Diffusible hydrogen content of the deposited metal: �5.0ml/100g (thermal conductivity method or mercury method) X-ray radiographic inspection requirements: Level I X-ray radiographic inspection requirements: Level I + + Reference current (DC ) Reference current (DC ) Welding rod 瘀瘀eldmg rod 䌀䐀3. 2 䌀䐀4. 0 䌀䐀5. 0 䌀䐀 3. 2 䌀䐀4. 0 䌀䐀5. 0 diameter (mm) diameter· (mm) Welding current (A) 80~120 130~180 170~240 Welding current (A) 80~120 130~180 170~240 Precautions: Welding position Welding position Precautions: ° ° 1 Welding rods must be baked at 350 C for 1 h before 1.The welding rods must be baked at about 400 C for 1 h ° welding and they shall be baked immediately before use. before welding.and then placed in a 100-150 C thermostat. ° Place it in a 100-150 C thermostat and take it out They shall be taken out immediately before use. immediately before use. 2.The rust, oil stain, water and other impurities of the 2.The weldment must be cleaned of impurities such as weldment must be removed before welding. oil stain, rust and water before welding. 3Short arc operation and string bead are preferred for welding. 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd - - - - - - - - - - - - 55 54 - - - - - - - - - - - - 吀椀anjin Golden Bridge Welding Materials Group Co.,Ltd