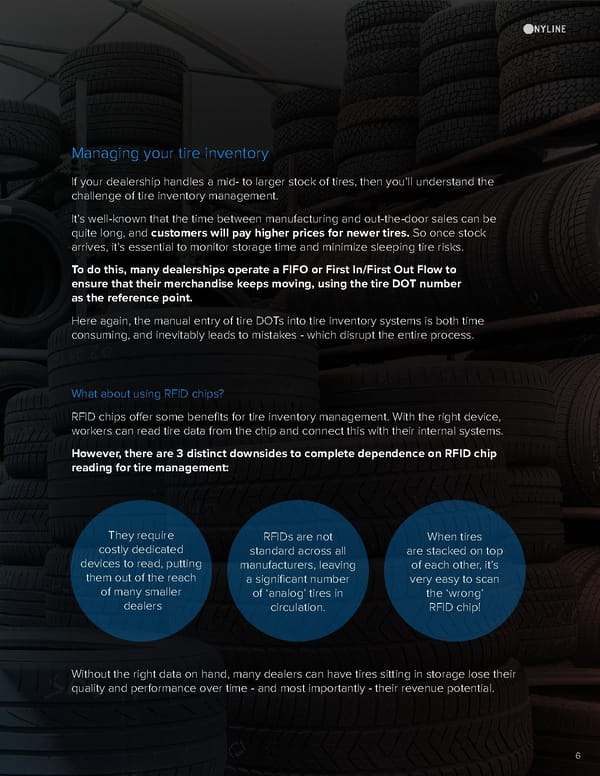

What about using RFID chips? RFID chips offer some benefits for tire inventory management. With the right device, workers can read tire data from the chip and connect this with their internal systems. However, there are 3 distinct downsides to complete dependence on RFID chip reading for tire management: Without the right data on hand, many dealers can have tires sitting in storage lose their quality and performance over time - and most importantly - their revenue potential. 6 They require costly dedicated devices to read, putting them out of the reach of many smaller dealers RFIDs are not standard across all manufacturers, leaving a significant number of ‘analog’ tires in circulation. When tires are stacked on top of each other, it’s very easy to scan the ‘wrong’ RFID chip! Managing your tire inventory If your dealership handles a mid- to larger stock of tires, then you’ll understand the challenge of tire inventory management. It’s well-known that the time between manufacturing and out-the-door sales can be quite long, and customers will pay higher prices for newer tires. So once stock arrives, it’s essential to monitor storage time and minimize sleeping tire risks. To do this, many dealerships operate a FIFO or First In/First Out Flow to ensure that their merchandise keeps moving, using the tire DOT number as the reference point. Here again, the manual entry of tire DOTs into tire inventory systems is both time consuming, and inevitably leads to mistakes - which disrupt the entire process.

Tire Services eBook Page 5 Page 7

Tire Services eBook Page 5 Page 7