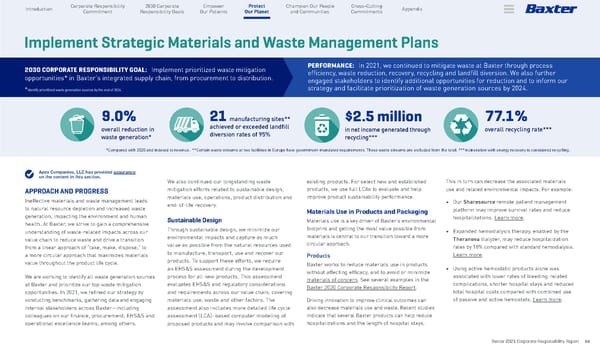

Baxter 2021 Corporate Responsibility Report 30 Protect Our Planet Corporate Responsibility Commitment Introduction 2030 Corporate Responsibility Goals Empower Our Patients Appendix Champion Our People and Communities Cross-Cutting Commitments Implement Strategic Materials and Waste Management Plans 2030 CORPORATE RESPONSIBILITY GOAL : Implement prioritized waste mitigation opportunities* in Baxter’s integrated supply chain, from procurement to distribution. * Identify prioritized waste generation sources by the end of 2024. PERFORMANCE: In 2021, we continued to mitigate waste at Baxter through process efficiency, waste reduction, recovery, recycling and landfill diversion. We also further engaged stakeholders to identify additional opportunities for reduction and to inform our strategy and facilitate prioritization of waste generation sources by 2024. 77.1% overall recycling rate*** 9.0% overall reduction in waste generation* *Compared with 2020 and indexed to revenue. **Certain waste streams at two facilities in Europe have government-mandated requirements. These waste streams are excluded from the total. ***Incineration with energy recovery is considered recycling. APPROACH AND PROGRESS Ineffective materials and waste management leads to natural resource depletion and increased waste generation, impacting the environment and human health. At Baxter, we strive to gain a comprehensive understanding of waste-related impacts across our value chain to reduce waste and drive a transition from a linear approach of “take, make, dispose,” to a more circular approach that maximizes materials value throughout the product life cycle. We are working to identify all waste generation sources at Baxter and prioritize our top waste mitigation opportunities. In 2021, we refined our strategy by conducting benchmarks, gathering data and engaging internal stakeholders across Baxter—including colleagues on our finance, procurement, EHS&S and operational excellence teams, among others. We also continued our longstanding waste mitigation efforts related to sustainable design, materials use, operations, product distribution and end-of-life recovery. Sustainable Design Through sustainable design, we minimize our environmental impacts and capture as much value as possible from the natural resources used to manufacture, transport, use and recover our products. To support these efforts, we require an EHS&S assessment during the development process for all new products. This assessment evaluates EHS&S and regulatory considerations and requirements across our value chain, covering materials use, waste and other factors. The assessment also includes more detailed life cycle assessment (LCA)–based computer modeling of proposed products and may involve comparison with existing products. For select new and established products, we use full LCAs to evaluate and help improve product sustainability performance. Materials Use in Products and Packaging Materials use is a key driver of Baxter’s environmental footprint and getting the most value possible from materials is central to our transition toward a more circular approach. Products Baxter works to reduce materials use in products without affecting efficacy, and to avoid or minimize materials of concern. See several examples in the Baxter 2020 Corporate Responsibility Report. Driving innovation to improve clinical outcomes can also decrease materials use and waste. Recent studies indicate that several Baxter products can help reduce hospitalizations and the length of hospital stays. This in turn can decrease the associated materials use and related environmental impacts. For example: • Our Sharesource remote patient management platform may improve survival rates and reduce hospitalizations. Learn more. • Expanded hemodialysis therapy, enabled by the Theranova dialyzer, may reduce hospitalization rates by 18% compared with standard hemodialysis. Learn more. • Using active hemostatic products alone was associated with lower rates of bleeding-related complications, shorter hospital stays and reduced total hospital costs compared with combined use of passive and active hemostats. Learn more. Apex Companies, LLC has provided assurance on the content in this section. 21 manufacturing sites** achieved or exceeded landfill diversion rates of 95% $2.5 million in net income generated through recycling*** Protect Our Planet Corporate Responsibility Commitment Introduction 2030 Corporate Responsibility Goals Empower Our Patients Appendix Champion Our People and Communities Cross-Cutting Commitments

Baxter Corporate Responsibility Report Page 29 Page 31

Baxter Corporate Responsibility Report Page 29 Page 31