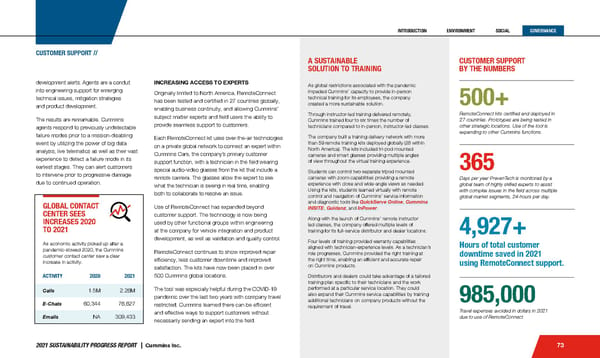

73 ACTIVITY 2020 2021 Calls 1.5M 2.26M E-Chats 60,344 76,627 Emails NA 309,433 GLOBAL CONTACT CENTER SEES INCREASES 2020 TO 2021 As economic activity picked up after a pandemic-slowed 2020, the Cummins customer contact center saw a clear increase in activity. INCREASING ACCESS TO EXPERTS Originally limited to North America, RemoteConnect has been tested and certified in 27 countries globally, enabling business continuity, and allowing Cummins’ subject matter experts and field users the ability to provide seamless support to customers. Each RemoteConnect kit uses over-the-air technologies on a private global network to connect an expert within Cummins Care, the company’s primary customer support function, with a technician in the field wearing special audio-video glasses from the kit that include a remote camera. The glasses allow the expert to see what the technician is seeing in real time, enabling both to collaborate to resolve an issue. Use of RemoteConnect has expanded beyond customer support. The technology is now being used by other functional groups within engineering at the company for vehicle integration and product development, as well as validation and quality control. RemoteConnect continues to show improved repair efficiency, less customer downtime and improved satisfaction. The kits have now been placed in over 500 Cummins global locations. The tool was especially helpful during the COVID-19 pandemic over the last two years with company travel restricted. Cummins learned there can be efficient and effective ways to support customers without necessarily sending an expert into the field. CUSTOMER SUPPORT // A SUSTAINABLE SOLUTION TO TRAINING As global restrictions associated with the pandemic impeded Cummins’ capacity to provide in-person technical training for its employees, the company created a more sustainable solution. Through instructor-led training delivered remotely, Cummins trained four to six times the number of technicians compared to in-person, instructor-led classes. The company built a training delivery network with more than 59 remote training kits deployed globally (28 within North America). The kits included tri-pod mounted cameras and smart glasses providing multiple angles of view throughout the virtual training experience. Students can control two separate tripod mounted cameras with zoom capabilities providing a remote experience with close and wide-angle views as needed. Using the kits, students learned virtually with remote control and navigation of Cummins’ service information and diagnostic tools like QuickServe Online , Cummins INSITE , Guidanz , and InPower . Along with the launch of Cummins’ remote instructor led classes, the company offered multiple levels of training for its full-service distributor and dealer locations. Four levels of training provided warranty capabilities aligned with technician-experience levels. As a technician’s role progresses, Cummins provided the right training at the right time, enabling an efficient and accurate repair on Cummins products. Distributors and dealers could take advantage of a tailored training plan specific to their technicians and the work performed at a particular service location. They could also expand their Cummins service capabilities by training additional technicians on company products without the requirement of travel. CUSTOMER SUPPORT BY THE NUMBERS 985,000 Travel expenses avoided in dollars in 2021 due to use of RemoteConnect. 4,927+ Hours of total customer downtime saved in 2021 using RemoteConnect support. 365 Days per year PrevenTech is monitored by a global team of highly skilled experts to assist with complex issues in the field across multiple global market segments, 24-hours per day. 500+ RemoteConnect kits certified and deployed in 27 countries. Prototypes are being tested in other strategic locations. Use of the tool is expanding to other Cummins functions. development alerts. Agents are a conduit into engineering support for emerging technical issues, mitigation strategies and product development. The results are remarkable. Cummins agents respond to previously undetectable failure modes prior to a mission-disabling event by utilizing the power of big data analysis, live telematics as well as their vast experience to detect a failure mode in its earliest stages. They can alert customers to intervene prior to progressive damage due to continued operation. 2021 SUSTAINABILITY PROGRESS REPORT | Cummins Inc.

Cummins Sustainability Progress Report Page 73 Page 75

Cummins Sustainability Progress Report Page 73 Page 75