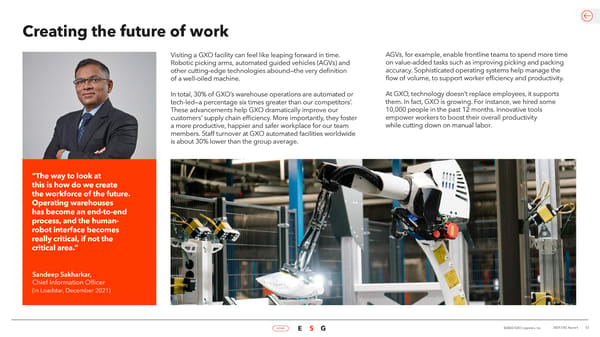

Creating the future of work Visiting a GXO facility can feel like leaping forward in time. AGVs, for example, enable frontline teams to spend more time Robotic picking arms, automated guided vehicles (AGVs) and on value-added tasks such as improving picking and packing other cutting-edge technologies abound—the very definition accuracy. Sophisticated operating systems help manage the of a well-oiled machine. flow of volume, to support worker efficiency and productivity. In total, 30% of GXO’s warehouse operations are automated or At GXO, technology doesn’t replace employees, it supports tech-led—a percentage six times greater than our competitors’. them. In fact, GXO is growing. For instance, we hired some These advancements help GXO dramatically improve our 10,000 people in the past 12 months. Innovative tools customers’ supply chain efficiency. More importantly, they foster empower workers to boost their overall productivity a more productive, happier and safer workplace for our team while cutting down on manual labor. members. Staff turnover at GXO automated facilities worldwide is about 30% lower than the group average. “The way to look at this is how do we create the workforce of the future. Operating warehouses has become an end-to-end process, and the human- robot interface becomes really critical, if not the critical area.” Sandeep Sakharkar, Chief Information Officer (in Loadstar, December 2021) HOME E S G ©2022 GXO Logisitcs, Inc. 2021 ESG Report | 57

GXO Logistics ESG Report Page 56 Page 58

GXO Logistics ESG Report Page 56 Page 58