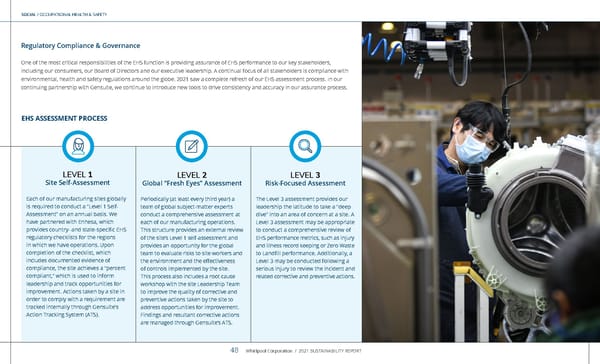

SOCIAL / OCCUPATIONAL HEALTH & SAFETY Regulatory Compliance & Governance One of the most critical responsibilities of the EHS function is providing assurance of EHS performance to our key stakeholders, including our consumers, our Board of Directors and our executive leadership. A continual focus of all stakeholders is compliance with environmental, health and safety regulations around the globe. 2021 saw a complete refresh of our EHS assessment process. In our continuing partnership with Gensuite, we continue to introduce new tools to drive consistency and accuracy in our assurance process. LEVEL 3 Risk-Focused Assessment The Level 3 assessment provides our leadership the latitude to take a “deep dive” into an area of concern at a site. A Level 3 assessment may be appropriate to conduct a comprehensive review of EHS performance metrics, such as injury and illness record keeping or Zero Waste to Landfill performance. Additionally, a Level 3 may be conducted following a serious injury to review the incident and related corrective and preventive actions. LEVEL 1 Site Self-Assessment Each of our manufacturing sites globally is required to conduct a “Level 1 Self- Assessment” on an annual basis. We have partnered with Enhesa, which provides country- and state-specific EHS regulatory checklists for the regions in which we have operations. Upon completion of the checklist, which includes documented evidence of compliance, the site achieves a “percent compliant,” which is used to inform leadership and track opportunities for improvement. Actions taken by a site in order to comply with a requirement are tracked internally through Gensuite’s Action Tracking System (ATS). LEVEL 2 Global “Fresh Eyes” Assessment Periodically (at least every third year) a team of global subject-matter experts conduct a comprehensive assessment at each of our manufacturing operations. This structure provides an external review of the site’s Level 1 self-assessment and provides an opportunity for the global team to evaluate risks to site workers and the environment and the effectiveness of controls implemented by the site. This process also includes a root cause workshop with the site Leadership Team to improve the quality of corrective and preventive actions taken by the site to address opportunities for improvement. Findings and resultant corrective actions are managed through Gensuite’s ATS. EHS ASSESSMENT PROCESS Whirlpool Corporation / 2021 SUSTAINABILITY REPORT 48

Whirlpool Sustainability Report Page 47 Page 49

Whirlpool Sustainability Report Page 47 Page 49