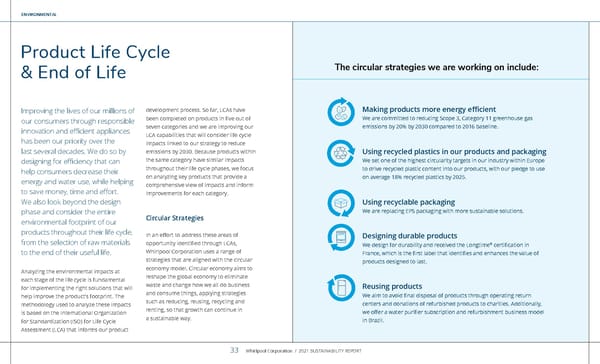

ENVIRONMENTAL / OUR ESG APPROACH ENVIRONMENTAL Product Life Cycle & End of Life Improving the lives of our millions of our consumers through responsible innovation and efficient appliances has been our priority over the last several decades. We do so by designing for efficiency that can help consumers decrease their energy and water use, while helping to save money, time and effort. We also look beyond the design phase and consider the entire environmental footprint of our products throughout their life cycle, from the selection of raw materials to the end of their useful life. Analyzing the environmental impacts at each stage of the life cycle is fundamental for implementing the right solutions that will help improve the product’s footprint. The methodology used to analyze these impacts is based on the International Organization for Standardization (ISO) for Life Cycle Assessment (LCA) that informs our product development process. So far, LCAs have been completed on products in five out of seven categories and we are improving our LCA capabilities that will consider life cycle impacts linked to our strategy to reduce emissions by 2030. Because products within the same category have similar impacts throughout their life cycle phases, we focus on analyzing key products that provide a comprehensive view of impacts and inform improvements for each category. Circular Strategies In an effort to address these areas of opportunity identified through LCAs, Whirlpool Corporation uses a range of strategies that are aligned with the circular economy model. Circular economy aims to reshape the global economy to eliminate waste and change how we all do business and consume things, applying strategies such as reducing, reusing, recycling and renting, so that growth can continue in a sustainable way. Making products more energy efficient We are committed to reducing Scope 3, Category 11 greenhouse gas emissions by 20% by 2030 compared to 2016 baseline. Using recycled plastics in our products and packaging We set one of the highest circularity targets in our industry within Europe to drive recycled plastic content into our products, with our pledge to use on average 18% recycled plastics by 2025. Using recyclable packaging We are replacing EPS packaging with more sustainable solutions. Designing durable products We design for durability and received the Longtime ® certification in France, which is the first label that identifies and enhances the value of products designed to last. Reusing products We aim to avoid final disposal of products through operating return centers and donations of refurbished products to charities. Additionally, we offer a water purifier subscription and refurbishment business model in Brazil. The circular strategies we are working on include: Whirlpool Corporation / 2021 SUSTAINABILITY REPORT 33 Whirlpool Corporation / 2021 SUSTAINABILITY REPORT 33

Whirlpool Sustainability Report Page 32 Page 34

Whirlpool Sustainability Report Page 32 Page 34