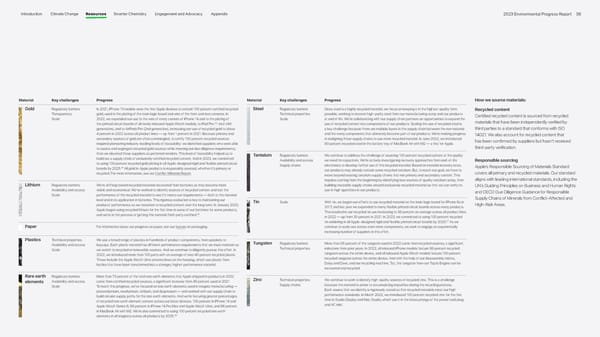

Introduction Climate Change Resources Smarter Chemistry Engagement and Advocacy Appendix 2023 Environmental Progress Report 38 Material Key challenges Progress Material Key challenges Progress How we source materials: Gold Regulatory barriers In 2021, iPhone 13 models were the first Apple devices to contain 100 percent certified recycled Steel Regulatory barriers Since steel is a highly recycled material, we focus on keeping it in the highest-quality form Recycled content Transparency gold, used in the plating of the main logic board and wire of the front and rear cameras. In Technical properties possible, working to recover high-purity steel from our manufacturing scrap and our products Certified recycled content is sourced from recycled Scale 2022, we expanded our use to the wire of every camera of iPhone 14 and to the plating of Scale at end of life. We’re collaborating with our supply chain partners on opportunities to expand the materials that have been independently verified by the printed circuit boards of all newly released Apple Watch models, to iPad Pro 11-inch (4th use of recycled content into components of our products. Scaling the use of recycled steel is generation), and to AirPods Pro (2nd generation), increasing our use of recycled gold to about a key challenge because there are multiple layers in the supply chain between the raw material third parties to a standard that conforms with ISO 4 percent in 2022 across all product lines — up from 1 percent in 2021. Because primary and and the many components that ultimately become part of our products. We’re making progress 14021. We also account for recycled content that secondary sources of gold are often commingled, to certify 100 percent recycled sources in realigning these supply chains to use more recycled material. In June 2022, we introduced has been confirmed by suppliers but hasn’t received required pioneering industry-leading levels of traceability: we identified suppliers who were able 90 percent recycled steel in the battery tray of MacBook Air with M2 — a first for Apple. third-party verification. to source and segregate recycled gold sources while meeting our due diligence requirements; then we elevated these suppliers as preferred vendors. This level of traceability helped us to Tantalum Regulatory barriers We continue to address the challenge of sourcing 100 percent recycled content at the quality build out a supply chain of exclusively certified recycled content. And in 2023, we committed Availability and access we need for capacitors. We’re actively investigating recovery approaches from end-of-life Responsible sourcing to using 100 percent recycled gold plating in all Apple-designed rigid and flexible printed circuit Supply chains electronics to develop further use of this recycled material. Based on material recovery rates, Apple’s Responsible Sourcing of Materials Standard boards by 2025. 44 All gold in Apple products is responsibly sourced, whether it’s primary or our products may already contain some recycled tantalum. But, to reach our goal, we have to recycled. For more information, see our Conflict Minerals Report . move beyond existing tantalum supply chains that mix primary and secondary content. This covers all primary and recycled materials. Our standard requires starting from the beginning by identifying new sources of quality tantalum scrap, then aligns with leading international standards, including the Lithium Regulatory barriers We’re shifting toward recycled materials recovered from batteries as they become more building traceable supply chains around exclusively recycled material so that we can verify its UN’s Guiding Principles on Business and Human Rights Availability and access viable and economical. We’ve worked to identify sources of recycled content and test the use in high quantities in our products. and OECD Due Diligence Guidance for Responsible Scale performance of the recycled material to see if it meets our requirements — both at the material Supply Chains of Minerals from Conflict-Affected and level and in its application in batteries. This rigorous evaluation is key to maintaining our Tin Scale With tin, we began our efforts to use recycled material on the main logic board for iPhone 6s in products’ performance as we transition to recycled content over the long term. In January 2023, 2017, and last year we expanded to many flexible printed circuit boards across many products. High-Risk Areas. Apple began using recycled lithium for the first time in some of our batteries for some products, This resulted in our recycled tin use increasing to 38 percent on average across all product lines and we’re in the process of getting this material third-party certified. 45 in 2022 — up from 30 percent in 2021. In 2023, we committed to using 100 percent recycled tin soldering in all Apple-designed rigid and flexible printed circuit boards by 2025. 47 As we Paper For information about our progress on paper, see our feature on packaging. continue to scale use across even more components, we seek to engage an exponentially increasing number of suppliers in this effort. Plastics Technical properties We use a broad range of plastics in hundreds of product components, from speakers to Tungsten Regulatory barriers More than 95 percent of the tungsten used in 2022 came from recycled sources, a significant Availability and access keycaps. Each plastic material has different performance requirements that we must maintain as Technical properties milestone from prior years. In 2022, all released iPhone models feature 99 percent recycled Scale we switch to recycled or renewable sources. And we continue to diligently pursue this effort. In tungsten across the entire device, and all released Apple Watch models feature 100 percent 2022, we introduced more than 100 parts with an average of over 40 percent recycled plastic. recycled tungsten across the entire device. And with the help of our disassembly robots, These include the Apple Watch Ultra antenna lines on the housing, which use plastic from Daisy and Dave, and our recycling machine, Taz, the tungsten from our Taptic Engine can be bottles that have been transformed into a stronger, higher-performance material. recovered and recycled. Rare earth Regulatory barriers More than 73 percent of the total rare earth elements that Apple shipped in products in 2022 Zinc Technical properties We continue to work to identify high-quality sources of recycled zinc. This is a challenge elements Availability and access came from certified recycled sources, a significant increase from 45 percent used in 2021. Supply chains because the material is prone to accumulating impurities during the recycling process. Scale To reach this progress, we’ve focused on rare earth elements used in magnet manufacturing — Each source that we identify is rigorously tested so that recycled materials meet our high praseodymium, neodymium, terbium, and dysprosium — and worked with our supply chain to performance standards. In March 2022, we introduced 100 percent recycled zinc for the first build circular supply paths for the rare earth elements. And we’re featuring greater percentages time in Studio Display and Mac Studio, which use it in the brass prongs of the power cord plug of recycled rare earth element content across our latest devices: 100 percent in iPhone 14 and and AC inlet. Apple Watch Series 8, 99 percent in iPhone 14 Pro Max and Apple Watch Ultra, and 98 percent in MacBook Air with M2. We’re also committed to using 100 percent recycled rare earth elements in all magnets across all products by 2025. 46

Apple Environmental | Immersive Page 37 Page 39

Apple Environmental | Immersive Page 37 Page 39