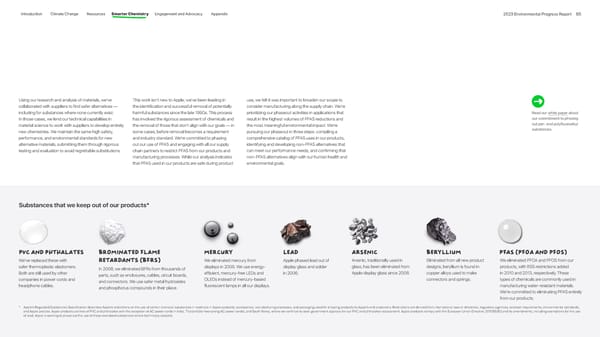

Introduction Climate Change Resources Smarter Chemistry Engagement and Advocacy Appendix 2023 Environmental Progress Report 65 Using our research and analysis of materials, we’ve This work isn’t new to Apple; we’ve been leading in use, we felt it was important to broaden our scope to collaborated with suppliers to find safer alternatives — the identification and successful removal of potentially consider manufacturing along the supply chain. We’re including for substances where none currently exist. harmful substances since the late 1990s. This process prioritizing our phaseout activities in applications that Read our white paper about In those cases, we lend our technical capabilities in has involved the rigorous assessment of chemicals and result in the highest volumes of PFAS reductions and our commitment to phasing material science to work with suppliers to develop entirely the removal of those that don’t align with our goals — in the most meaningful environmental impact. We’re out per- and polyfluoroalkyl new chemistries. We maintain the same high safety, some cases, before removal becomes a requirement pursuing our phaseout in three steps: compiling a substances. performance, and environmental standards for new and industry standard. We’re committed to phasing comprehensive catalog of PFAS uses in our products, alternative materials, submitting them through rigorous out our use of PFAS and engaging with all our supply identifying and developing non-PFAS alternatives that testing and evaluation to avoid regrettable substitutions. chain partners to restrict PFAS from our products and can meet our performance needs, and confirming that manufacturing processes. While our analysis indicates non-PFAS alternatives align with our human health and that PFAS used in our products are safe during product environmental goals. Substances that we keep out of our products* PVC and phthalates Brominated flame Mercury Lead Arsenic Beryllium PFAS (PFOA and PFOS) We’ve replaced these with retardants (BFRs) We eliminated mercury from Apple phased lead out of Arsenic, traditionally used in Eliminated from all new product We eliminated PFOA and PFOS from our safer thermoplastic elastomers. In 2008, we eliminated BFRs from thousands of displays in 2009. We use energy- display glass and solder glass, has been eliminated from designs, beryllium is found in products, with RSS restrictions added Both are still used by other parts, such as enclosures, cables, circuit boards, efficient, mercury-free LEDs and in 2006. Apple display glass since 2008. copper alloys used to make in 2010 and 2013, respectively. These companies in power cords and and connectors. We use safer metal hydroxides OLEDs instead of mercury-based connectors and springs. types of chemicals are commonly used in headphone cables. and phosphorus compounds in their place. fluorescent lamps in all our displays. manufacturing water-resistant materials. We’re committed to eliminating PFAS entirely from our products. * Apple ’s Regulated Substances Specification describes Apple’s restrictions on the use of certain chemical substances in materials in Apple products, accessories, manufacturing processes, and packaging used for shipping products to Apple’s end customers. Restrictions are derived from international laws or directives, regulatory agencies, ecolabel requirements, environmental standards, and Apple policies. Apple products are free of PVC and phthalates with the exception of AC power cords in India, Thailand (for two-prong AC power cords), and South Korea, where we continue to seek government approval for our PVC and phthalates replacement. Apple products comply with the European Union Directive 2011/65/EU and its amendments, including exemptions for the use of lead. Apple is working to phase out the use of these exempted substances where technically possible.

Apple Environmental | Immersive Page 64 Page 66

Apple Environmental | Immersive Page 64 Page 66