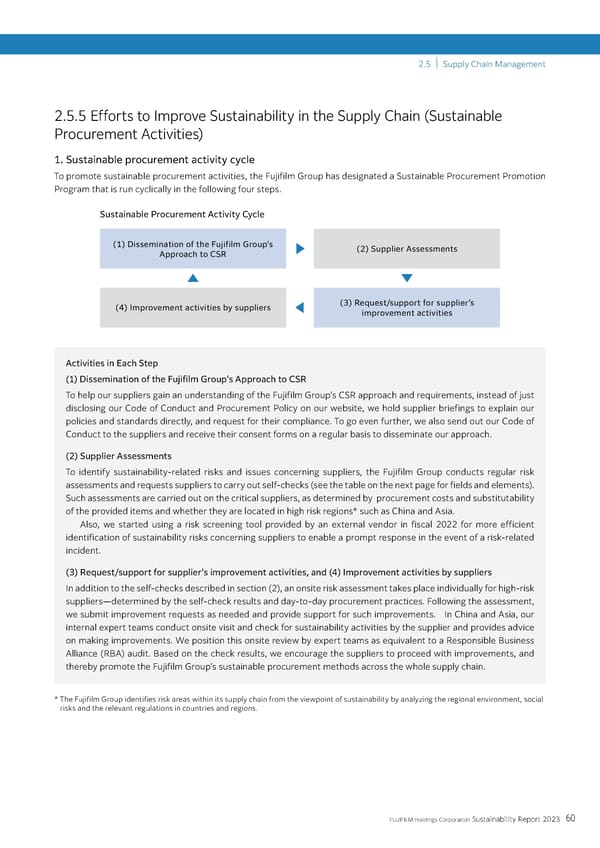

2.5 | Supply Chain Management 2.5.5 Efforts to Improve Sustainability in the Supply Chain (Sustainable Procurement Activities) 1. Sustainable procurement activity cycle To promote sustainable procurement activities, the Fujifilm Group has designated a Sustainable Procurement Promotion Program that is run cyclically in the following four steps. Sustainable Procurement Activity Cycle (1) Dissemination of the Fujifilm Group’s (2) Supplier Assessments Approach to CSR (4) Improvement activities by suppliers (3) Request/support for supplier’s improvement activities Activities in Each Step (1) Dissemination of the Fujifilm Group's Approach to CSR To help our suppliers gain an understanding of the Fujifilm Group’s CSR approach and requirements, instead of just disclosing our Code of Conduct and Procurement Policy on our website, we hold supplier briefings to explain our policies and standards directly, and request for their compliance. To go even further, we also send out our Code of Conduct to the suppliers and receive their consent forms on a regular basis to disseminate our approach. (2) Supplier Assessments To identify sustainability-related risks and issues concerning suppliers, the Fujifilm Group conducts regular risk assessments and requests suppliers to carry out self-checks (see the table on the next page for fields and elements). Such assessments are carried out on the critical suppliers, as determined by procurement costs and substitutability of the provided items and whether they are located in high risk regions* such as China and Asia. Also, we started using a risk screening tool provided by an external vendor in fiscal 2022 for more efficient identification of sustainability risks concerning suppliers to enable a prompt response in the event of a risk-related incident. (3) Request/support for supplier's improvement activities, and (4) Improvement activities by suppliers In addition to the self-checks described in section (2), an onsite risk assessment takes place individually for high-risk suppliers—determined by the self-check results and day-to-day procurement practices. Following the assessment, we submit improvement requests as needed and provide support for such improvements. In China and Asia, our internal expert teams conduct onsite visit and check for sustainability activities by the supplier and provides advice on making improvements. We position this onsite review by expert teams as equivalent to a Responsible Business Alliance (RBA) audit. Based on the check results, we encourage the suppliers to proceed with improvements, and thereby promote the Fujifilm Group’s sustainable procurement methods across the whole supply chain. * The Fujifilm Group identifies risk areas within its supply chain from the viewpoint of sustainability by analyzing the regional environment, social risks and the relevant regulations in countries and regions. 60 FUJIFILM Holdings Corporation Sustainability Report 2023

2023 | Sustainability Report Page 60 Page 62

2023 | Sustainability Report Page 60 Page 62