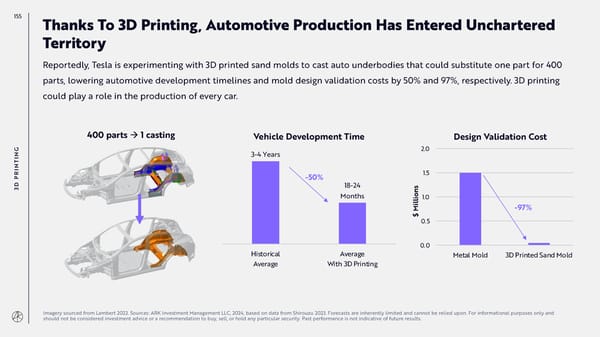

155 Thanks To 3D Printing, Automotive Production Has Entered Unchartered Territory Reportedly, Tesla is experimenting with 3D printed sand molds to cast auto underbodies that could substitute one part for 400 parts, lowering automotive development timelines and mold design validation costs by 50% and 97%, respectively. 3D printing could play a role in the production of every car. 400 parts à 1 casting Vehicle Development Time Design Validation Cost G 2.0 N 3-4 Years I T N I R 1.5 P -50% 3D 18-24 ns Months io1.0 l il -97% M $ 0.5 0.0 Historical Average Metal Mold 3D Printed Sand Mold Average With 3D Printing Imagery sourced from Lambert 2022. Sources: ARK Investment Management LLC, 2024, based on data from Shirouzu 2023. Forecasts are inherently limited and cannot be relied upon. For informational purposes only and should not be considered investment advice or a recommendation to buy, sell, or hold any particular security. Past performance is not indicative of future results.

Annual Research Report | Big Ideas 2024 Page 154 Page 156

Annual Research Report | Big Ideas 2024 Page 154 Page 156