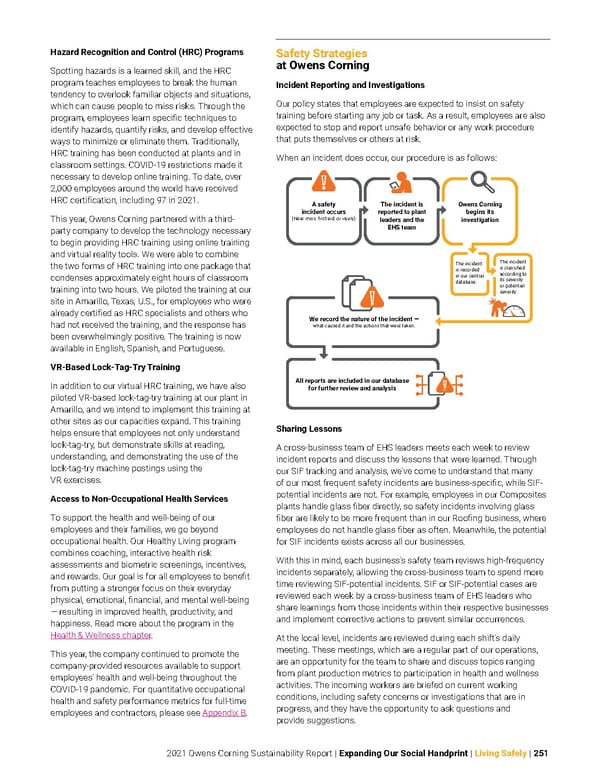

2021 Owens Corning Sustainability Report | Expanding Our Social Handprint | Living Safely | 251 Hazard Recognition and Control (HRC) Programs Spotting hazards is a learned skill, and the HRC program teaches employees to break the human tendency to overlook familiar objects and situations, which can cause people to miss risks. Through the program, employees learn specific techniques to identify hazards, quantify risks, and develop effective ways to minimize or eliminate them. Traditionally, HRC training has been conducted at plants and in classroom settings. COVID-19 restrictions made it necessary to develop online training. To date, over 2,000 employees around the world have received HRC certification, including 97 in 2021. This year, Owens Corning partnered with a third- party company to develop the technology necessary to begin providing HRC training using online training and virtual reality tools. We were able to combine the two forms of HRC training into one package that condenses approximately eight hours of classroom training into two hours. We piloted the training at our site in Amarillo, Texas, U.S., for employees who were already certified as HRC specialists and others who had not received the training, and the response has been overwhelmingly positive. The training is now available in English, Spanish, and Portuguese. VR-Based Lock-Tag-Try Training In addition to our virtual HRC training, we have also piloted VR-based lock-tag-try training at our plant in Amarillo, and we intend to implement this training at other sites as our capacities expand. This training helps ensure that employees not only understand lock-tag-try, but demonstrate skills at reading, understanding, and demonstrating the use of the lock-tag-try machine postings using the VR exercises. Access to Non-Occupational Health Services To support the health and well-being of our employees and their families, we go beyond occupational health. Our Healthy Living program combines coaching, interactive health risk assessments and biometric screenings, incentives, and rewards. Our goal is for all employees to benefit from putting a stronger focus on their everyday physical, emotional, financial, and mental well-being — resulting in improved health, productivity, and happiness. Read more about the program in the Health & Wellness chapter . This year, the company continued to promote the company-provided resources available to support employees’ health and well-being throughout the COVID-19 pandemic. For quantitative occupational health and safety performance metrics for full-time employees and contractors, please see Appendix B. Safety Strategies at Owens Corning Incident Reporting and Investigations Our policy states that employees are expected to insist on safety training before starting any job or task. As a result, employees are also expected to stop and report unsafe behavior or any work procedure that puts themselves or others at risk. When an incident does occur, our procedure is as follows: A saf ety incident occurs (Near miss, first aid, or injury ) The incident is repo rted to plant leaders and the EHS team Owens Corning begins its investigation The incident is recorded in our centr al database. The incident is classified according to its severity or potential severity . We record the nature of the incident — what caused it and the actions that were taken. All repo rts are included in our database for fu rther review and analysis Sharing Lessons A cross-business team of EHS leaders meets each week to review incident reports and discuss the lessons that were learned. Through our SIF tracking and analysis, we’ve come to understand that many of our most frequent safety incidents are business-specific, while SIF- potential incidents are not. For example, employees in our Composites plants handle glass fiber directly, so safety incidents involving glass fiber are likely to be more frequent than in our Roofing business, where employees do not handle glass fiber as often. Meanwhile, the potential for SIF incidents exists across all our businesses. With this in mind, each business’s safety team reviews high-frequency incidents separately, allowing the cross-business team to spend more time reviewing SIF-potential incidents. SIF or SIF-potential cases are reviewed each week by a cross-business team of EHS leaders who share learnings from those incidents within their respective businesses and implement corrective actions to prevent similar occurrences. At the local level, incidents are reviewed during each shift’s daily meeting. These meetings, which are a regular part of our operations, are an opportunity for the team to share and discuss topics ranging from plant production metrics to participation in health and wellness activities. The incoming workers are briefed on current working conditions, including safety concerns or investigations that are in progress, and they have the opportunity to ask questions and provide suggestions.

Owens Corning Sustainability Report Page 250 Page 252

Owens Corning Sustainability Report Page 250 Page 252