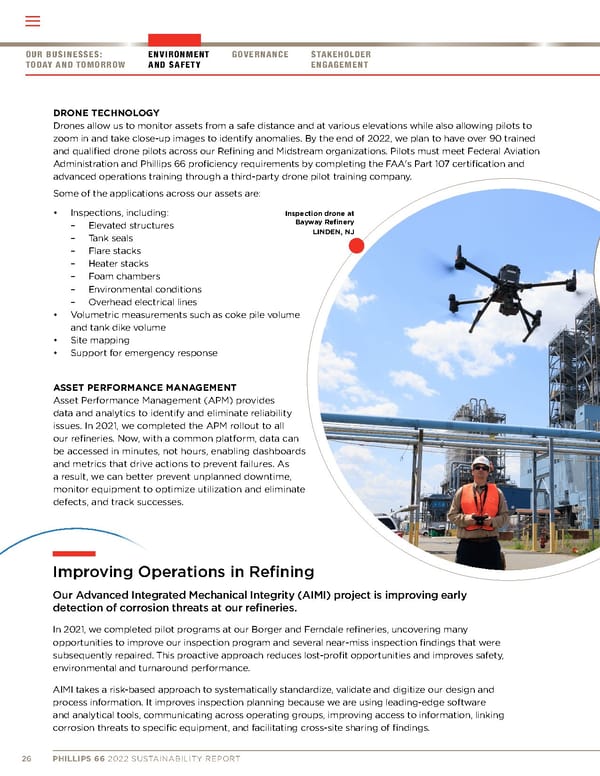

ASSET PERFORMANCE MANAGEMENT Asset Performance Management (APM) provides data and analytics to identify and eliminate reliability issues. In 2021, we completed the APM rollout to all our refineries. Now, with a common platform, data can be accessed in minutes, not hours, enabling dashboards and metrics that drive actions to prevent failures. As a result, we can better prevent unplanned downtime, monitor equipment to optimize utilization and eliminate defects, and track successes. Improving Operations in Refining Our Advanced Integrated Mechanical Integrity (AIMI) project is improving early detection of corrosion threats at our refineries. In 2021, we completed pilot programs at our Borger and Ferndale refineries, uncovering many opportunities to improve our inspection program and several near-miss inspection findings that were subsequently repaired. This proactive approach reduces lost-profit opportunities and improves safety, environmental and turnaround performance. AIMI takes a risk-based approach to systematically standardize, validate and digitize our design and process information. It improves inspection planning because we are using leading-edge software and analytical tools, communicating across operating groups, improving access to information, linking corrosion threats to specific equipment, and facilitating cross-site sharing of findings. DRONE TECHNOLOGY Drones allow us to monitor assets from a safe distance and at various elevations while also allowing pilots to zoom in and take close-up images to identify anomalies. By the end of 2022, we plan to have over 90 trained and qualified drone pilots across our Refining and Midstream organizations. Pilots must meet Federal Aviation Administration and Phillips 66 proficiency requirements by completing the FAA's Part 107 certification and advanced operations training through a third-party drone pilot training company. Some of the applications across our assets are: • Inspections, including: – Elevated structures – Tank seals – Flare stacks – Heater stacks – Foam chambers – Environmental conditions – Overhead electrical lines • Volumetric measurements such as coke pile volume and tank dike volume • Site mapping • Support for emergency response Inspection drone at Bayway Refinery LINDEN, NJ 26 PHILLIPS 66 2022 SUSTAINABILITY REPORT OUR BUSINESSES: TODAY AND TOMORROW ENVIRONMENT AND SAFETY GOVERNANCE STAKEHOLDER ENGAGEMENT

Philips 66 ESG Report Page 27 Page 29

Philips 66 ESG Report Page 27 Page 29