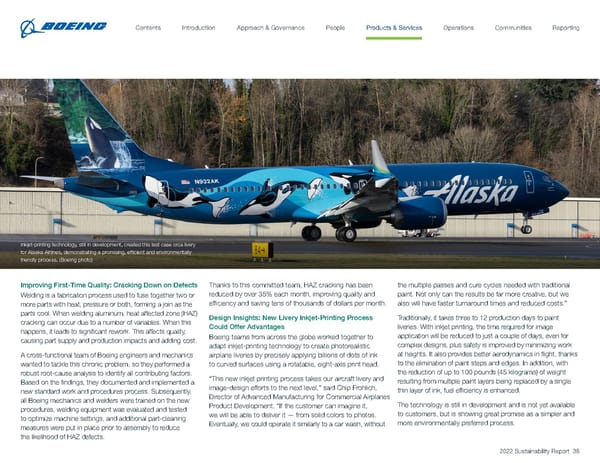

Inkjet-printing technology, still in development, created this test case orca livery for Alaska Airlines, demonstrating a promising, efficient and environmentally friendly process. (Boeing photo) Improving First-Time Quality: Cracking Down on Defects Welding is a fabrication process used to fuse together two or more parts with heat, pressure or both, forming a join as the parts cool. When welding aluminum, heat affected zone (HAZ) cracking can occur due to a number of variables. When this happens, it leads to significant rework. This affects quality, causing part supply and production impacts and adding cost. A cross-functional team of Boeing engineers and mechanics wanted to tackle this chronic problem, so they performed a robust root-cause analysis to identify all contributing factors. Based on the findings, they documented and implemented a new standard work and procedures process. Subsequently, all Boeing mechanics and welders were trained on the new procedures, welding equipment was evaluated and tested to optimize machine settings, and additional part-cleaning measures were put in place prior to assembly to reduce the likelihood of HAZ defects. Thanks to this committed team, HAZ cracking has been reduced by over 35% each month, improving quality and efficiency and saving tens of thousands of dollars per month. Design Insights: New Livery Inkjet-Printing Process Could Offer Advantages Boeing teams from across the globe worked together to adapt inkjet-printing technology to create photorealistic airplane liveries by precisely applying billions of dots of ink to curved surfaces using a rotatable, eight-axis print head. “This new inkjet printing process takes our aircraft livery and image-design efforts to the next level,” said Chip Frohlich, Director of Advanced Manufacturing for Commercial Airplanes Product Development. “If the customer can imagine it, we will be able to deliver it — from solid colors to photos. Eventually, we could operate it similarly to a car wash, without the multiple passes and cure cycles needed with traditional paint. Not only can the results be far more creative, but we also will have faster turnaround times and reduced costs.” Traditionally, it takes three to 12 production days to paint liveries. With inkjet printing, the time required for image application will be reduced to just a couple of days, even for complex designs, plus safety is improved by minimizing work at heights. It also provides better aerodynamics in flight, thanks to the elimination of paint steps and edges. In addition, with the reduction of up to 100 pounds (45 kilograms) of weight resulting from multiple paint layers being replaced by a single thin layer of ink, fuel efficiency is enhanced. The technology is still in development and is not yet available to customers, but is showing great promise as a simpler and more environmentally preferred process. 2022 Sustainability Report 36 Contents People Introduction Communities Operations Reporting Approach & Governance Products & Services

The Boeing Company 2022 Sustainability Report Page 35 Page 37

The Boeing Company 2022 Sustainability Report Page 35 Page 37