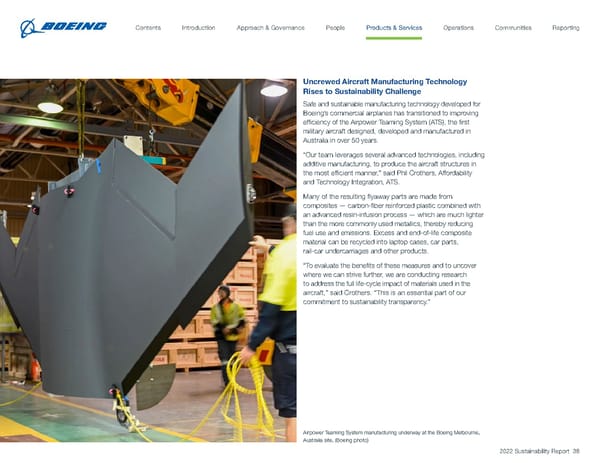

Uncrewed Aircraft Manufacturing Technology Rises to Sustainability Challenge Safe and sustainable manufacturing technology developed for Boeing’s commercial airplanes has transitioned to improving efficiency of the Airpower Teaming System (ATS), the first military aircraft designed, developed and manufactured in Australia in over 50 years. “Our team leverages several advanced technologies, including additive manufacturing, to produce the aircraft structures in the most efficient manner,” said Phil Crothers, Affordability and Technology Integration, ATS. Many of the resulting flyaway parts are made from composites — carbon-fiber reinforced plastic combined with an advanced resin-infusion process — which are much lighter than the more commonly used metallics, thereby reducing fuel use and emissions. Excess and end-of-life composite material can be recycled into laptop cases, car parts, rail-car undercarriages and other products. “To evaluate the benefits of these measures and to uncover where we can strive further, we are conducting research to address the full life-cycle impact of materials used in the aircraft,” said Crothers. “This is an essential part of our commitment to sustainability transparency.” Airpower Teaming System manufacturing underway at the Boeing Melbourne, Australia site. (Boeing photo) 2022 Sustainability Report 38 Contents People Introduction Communities Operations Reporting Approach & Governance Products & Services

The Boeing Company 2022 Sustainability Report Page 37 Page 39

The Boeing Company 2022 Sustainability Report Page 37 Page 39