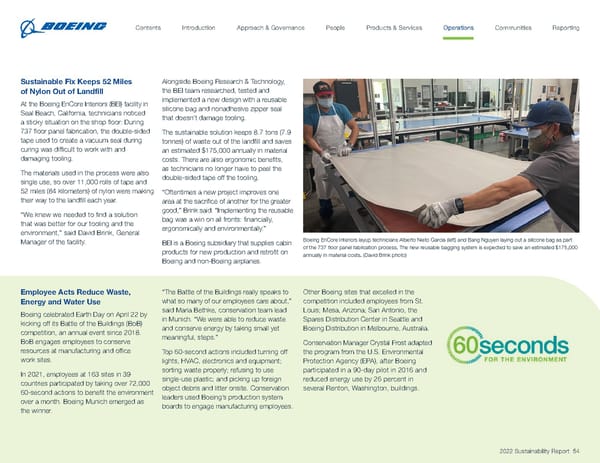

Sustainable Fix Keeps 52 Miles of Nylon Out of Landfill At the Boeing EnCore Interiors (BEI) facility in Seal Beach, California, technicians noticed a sticky situation on the shop floor: During 737 floor panel fabrication, the double-sided tape used to create a vacuum seal during curing was difficult to work with and damaging tooling. The materials used in the process were also single use, so over 11,000 rolls of tape and 52 miles (84 kilometers) of nylon were making their way to the landfill each year. “We knew we needed to find a solution that was better for our tooling and the environment,” said David Brink, General Manager of the facility. Alongside Boeing Research & Technology, the BEI team researched, tested and implemented a new design with a reusable silicone bag and nonadhesive zipper seal that doesn’t damage tooling. The sustainable solution keeps 8.7 tons (7.9 tonnes) of waste out of the landfill and saves an estimated $175,000 annually in material costs. There are also ergonomic benefits, as technicians no longer have to peel the double-sided tape off the tooling. “Oftentimes a new project improves one area at the sacrifice of another for the greater good,” Brink said. “Implementing the reusable bag was a win on all fronts: financially, ergonomically and environmentally.” BEI is a Boeing subsidiary that supplies cabin products for new production and retrofit on Boeing and non-Boeing airplanes. Boeing EnCore Interiors layup technicians Alberto Nieto Garcia (left) and Bang Nguyen laying out a silicone bag as part of the 737 floor panel fabrication process. The new reusable bagging system is expected to save an estimated $175,000 annually in material costs. (David Brink photo) Employee Acts Reduce Waste, Energy and Water Use Boeing celebrated Earth Day on April 22 by kicking off its Battle of the Buildings (BoB) competition, an annual event since 2018. BoB engages employees to conserve resources at manufacturing and office work sites. In 2021, employees at 163 sites in 39 countries participated by taking over 72,000 60-second actions to benefit the environment over a month. Boeing Munich emerged as the winner. “The Battle of the Buildings really speaks to what so many of our employees care about,” said Maria Bethke, conservation team lead in Munich. “We were able to reduce waste and conserve energy by taking small yet meaningful, steps.” Top 60-second actions included turning off lights, HVAC, electronics and equipment; sorting waste properly; refusing to use single-use plastic; and picking up foreign object debris and litter onsite. Conservation leaders used Boeing’s production system boards to engage manufacturing employees. Other Boeing sites that excelled in the competition included employees from St. Louis; Mesa, Arizona; San Antonio, the Spares Distribution Center in Seattle and Boeing Distribution in Melbourne, Australia. Conservation Manager Crystal Frost adapted the program from the U.S. Environmental Protection Agency (EPA), after Boeing participated in a 90-day pilot in 2016 and reduced energy use by 26 percent in several Renton, Washington, buildings. 2022 Sustainability Report 54 Contents People Introduction Communities Operations Reporting Approach & Governance Products & Services

The Boeing Company 2022 Sustainability Report Page 53 Page 55

The Boeing Company 2022 Sustainability Report Page 53 Page 55