General Motors Sustainability Report

2021 Sustainability Report ev erybody in.

Our vision of a world with zero crashes, zero emissions and zero congestion requires an everybody in approach. That’s why we’re accelerating our all-electric future and extending our technologies beyond our vehicles to meet the world’s growing demand for more zero-emissions solutions. Today, the GM team is working with an unprecedented sense of urgency, decisiveness, agility and breadth to take everyone on a journey to a more equitable, safe and all-electric future. On the Cover 2023 Cadillac LYRIQ Debut Edition available Summer 2022, by reservation only. Additional LYRIQ models available starting Fall 2022. See dealer for details. Vehicle not available for sale. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 1

About This Report General Motors is committed to publicly reporting on sustainability-related topics on an annual basis, discussing the opportunities and challenges that we encounter as we work to enhance performance and conduct business in the most responsible manner possible. This report has been prepared according to Global Reporting Initiative (GRI) Standards: Comprehensive Option and includes responses to the Sustainability Accounting Standards Board (SASB) framework—Transportation Standards and the Financial Stability Board Task Force on Climate-related Financial Disclosures (TCFD). Responses to sustainability-related frameworks and standards as well as assurance statements can be found in the 2021 Sustainability Supplement, which is available for download on gmsustainability.com. This report covers certain sustainability metrics and data for GM as of and during the year ended December 31, 2021, as applicable, unless otherwise stated. In instances where select information is provided from an earlier period or early 2022, that is noted in the report. The report is limited to automotive operations wholly owned and/or operated by GM. Unless otherwise stated, GM Financial, our financing services provider, and Cruise, our autonomous vehicle subsidiary, are not included in the report. In some instances, data has been included for operations in which GM’s interest is through joint ventures, including our automotive China joint ventures. In these instances, the inclusion of that data is noted. Dollar amounts presented within this report are stated in U.S. dollars. This report was published on April 28, 2022. We annually contract an independent third-party verification of a selection of greenhouse gas (GHG) and certain sustainability data assertions for our global operations. The verification statements and applicable data assertions can be found in the 2021 Sustainability Supplement. This report provides an overview of some of GM’s long-term goals and aspirations, and efforts in support of those goals and aspirations. Some material is derived from other company documents, and links are provided to those documents where appropriate. With respect to goals, commitments and aspirational or otherwise forward-looking statements in this report, actual results may differ, possibly materially. The report also includes certain numbers that are estimates or approximations and that may be based on assumptions. We believe that the estimates employed are appropriate and reasonable; however, due to inherent uncertainties in making estimates and assumptions, actual results could differ from the original estimates. Additional information with respect to forward-looking statements can be found on page 120 . Solely for convenience, trademarks and tradenames referred to in this report may appear without the ® or ™ symbols, but such references are not intended to indicate, in any way, that we will not assert, to the fullest extent under applicable law, our rights or the right of the applicable licensor to these trademarks and tradenames. Products Disclosure In this report, depicted vehicles and features may be simulated or preproduction and are subject to change. Additionally, certain products are not currently available or are subject to limited availability. For vehicle availability and feature use and limitations, including details relating to advanced safety and driver assistance features, consult the vehicle’s Owner’s Manual and brand’s website. IN THIS REPORT Introduction 1 Reducing Carbon Emissions 14 Designing for the Environment 31 Advancing Transformative Technologies 40 Earning Customers for Life 47 Keeping People Safe 52 Developing Talented & Diverse People 63 Upholding Human Rights 77 Supporting Supplier Responsibility 81 Building More Inclusive Communities 98 Ensuring Responsible Governance 104 Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 2

MARY BARRA Leadership Message Earlier this year, I took a driverless ride through San Francisco in a fully electric Cruise autonomous vehicle (AV). It was one of the most inspiring moments of my career, and it reinforced my belief that our opportunity to change the world has never been clearer or closer. During a challenging 2021, a resilient and focused GM team continued to make significant progress toward our vision of a world with zero crashes, zero emissions and zero congestion. Our culture of innovation, which begins with our employees, is unlocking once-in-a-lifetime opportunities to create a better and safer future for all. We delivered to customers the GMC HUMMER EV supertruck and BrightDrop Zevo 600 van, the first-ever electric vehicles (EVs) featuring our Ultium platform, and we have since announced the Chevrolet Silverado EV and Chevrolet Equinox crossover EV—with many more to follow. Production of the sold-out Debut Edition of the Cadillac LYRIQ SUV is underway in Tennessee, and next month we will begin accepting orders for the next editions. Cruise is now at the cusp of commercializing accessible and zero-emissions ride-hailing services. Our transition to EVs and AVs is at the heart of our technology- and software-driven growth strategy. We will continue to increase our investments in these vehicles and new services as we progress toward decarbonizing our business. In fact, we are accelerating our work this year to meet increasing demand for our EVs. We are expanding our global EV manufacturing capacity to over 2 million vehicles by the end of 2025. Half of that will be in North America, where we have set a target to produce 400,000 EVs over the next 24 months—with the ultimate goal of becoming the EV market leader. Our commitments and investments reflect our sense of urgency to get everybody in an EV, and transform our vision into a reality. It’s also imperative that this future be inclusive, including our diverse Board, our workforce and our business partners. Industry-leading innovations like Ultium and Cruise are possible because of a culture at GM that encourages and values diverse ideas and perspectives. As part of our aspiration to be the world’s most inclusive company, we have also launched an internal Inclusivity Index to measure our progress, and we use the results to inform future actions. The brighter and more inclusive future we envision also extends to the communities where we live, work and play. Last year, to meet unique community needs, we provided more than $85 million in cash and in-kind donations to hundreds of local nonprofit partners, with a focus on education, skills and literacy training, climate equity programs and road safety. I am excited about the progress we are making toward reimagining how our customers and communities will move through the world, just as we did more than a century ago. I invite you to learn more in this report, and see why I am so optimistic about the road ahead. Mary T. Barra Chair and CEO I am excited about the progress we are making toward reimagining how our customers and communities will move through the world, just as we did more than a century ago.” Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 3

Powering Growth With Purpose We pioneer the innovations that move and connect people to what matters General Motors is in the midst of a transformation that includes our accelerated transition to EVs and AVs. We are rethinking how and, in many cases, where we work. We are taking bold actions to make our business carbon neutral, and we are broadening our social impact by aiming to help create a zero-emissions future that is both inclusive and equitable. We are also laser-focused on our aspiration to become the most inclusive company in the world. For these reasons, the timing felt right to revisit the question of why we exist and to crystallize and articulate our Purpose. After extensive work by the Board, our Senior Leadership Team and a diverse, cross-functional global team of colleagues, we recently introduced our Purpose statement to our full team. For each and every one of us at General Motors, it’s the answer to why we exist: We pioneer the innovations that move and connect people to what matters. It’s a simple but powerful statement that honors our heritage of innovation, captures who we are today when we’re at our best and looks ahead. By defining our Purpose, it’s much easier to keep it front and center. Behaviors Our eight GM behaviors are the foundation of our culture and how we think and act in service of our Purpose. BE INCLUSIVE I create moments every day that value backgrounds, opinions and ideas that may be different than my own. THINK CUSTOMER I consider the customers’ needs in everything I do. INNOVATE NOW I see things not as they are but as they could be. LOOK AHEAD I make decisions now with the long-term view in mind, and I anticipate what lies ahead. ONE TEAM I collaborate cross-functionally to achieve enterprisewide results. BE BOLD I respectfully speak up, exchange feedback and boldly share ideas without fear. IT’S ON ME I take accountability for safety and my own actions, behaviors and results. WIN WITH INTEGRITY I have a relentless desire to win and do it with integrity. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance

How GM Creates Value The needs of our customers are at the forefront of every decision we make. Today, we’re working to leverage our core business strengths to find new market opportunities that solve challenges for both individual customers and society at large. For example, we leveraged our Ultium battery platform to launch BrightDrop, which is focused on developing and commercializing smarter ways to deliver goods and services. And, Cruise is developing autonomous robo-taxis that we believe will reduce congestion in cities and improve safety. Our Vision ZERO crashes, ZERO emissions and ZERO congestion Our Growth Strategy This diagram shows an illustrative overview of some of GM’s performance indicators and is not meant to be inclusive of all key performance indicators (KPIs); rather, it is an example of how GM creates value for our stakeholders. Details on KPIs can be found in each of the corresponding sections. PRODUCT LEADERSHIP DRIVE EV/AV MONETIZE EXISTING & NEW BUSINESS DOMINANCE TRUCK & SUV ENTERPRISE LEVERAGE SCALE WORKPLACE OF CHOICE IMPACT SOCIAL SEGMENTS & SERVICES LAUNCH NEW PLATFORMS ADVANCE CUSTOMER EXPERIENCE REIMAGINE THE Deliver world-class customer interactions LEAD IN WORLD-CLASS DIGITAL CAPABILITY Inputs: GM Capital HUMAN CAPITAL • ~146,000 employees • 11 employee resource groups (ERGs) • 6 Global Diversity, Equity and Inclusion (DEI) Councils • 18,940 approximate global supplier count FINANCIAL CAPITAL • $128B automotive assets • $36.8B automotive liquidity • $7. 4B capital expenditures • $76B approximate supply chain spend INFRASTRUCTURE CAPITAL • 100+ facilities • 12,340 dealerships INTELLECTUAL CAPITAL • $ 7.9B R&D spend (inclusive of GM Financial and Cruise) • GM Global Innovation Team SOCIAL AND RELATIONSHIP CAPITAL • $50M Climate Equity Fund • $22M committed through the Justice and Inclusion Fund • $87M in cash and in-kind donations NATURAL CAPITAL • 25,304 ML water withdrawn • ~329,000 materials and services purchased • 45.2 GJ energy used Outputs: Value Created HUMAN CAPITAL: Our Employees • 2.9M+ training hours • 10,229 global salary promotions • Announced $7B investment in four Michigan manufacturing sites, expected to create 4,000 new jobs and retain 1,000 jobs FINANCIAL CAPITAL: Our Shareholders • $114B automotive net sales and revenue • $10B net income (inclusive of GM Financial and Cruise) • $ 9.7B net automotive cash provided by operating activities INFRASTRUCTURE CAPITAL: Our Customers • 6 .3M vehicles sold • 5 0 vehicle models with one or more Advanced Driver Assistance Systems (ADAS) • Increased EV charging infrastructure INTELLECTUAL CAPITAL: Our Customers • N ew solutions and services such as OnStar Guardian, BrightDrop, Ultifi, and Ultium batteries • S afety technologies SOCIAL AND RELATIONSHIP CAPITAL: Our Communities • 19 nonprofits received Climate Equity Fund grants • ~$ 6B North America Tier I and Tier II diverse supplier spend (including media) • $ 46M in grantmaking to support a portfolio of 364 U.S.-based nonprofit projects NATURAL CAPITAL: Our Planet • 1 .2M metric tons waste diverted from landfills and incinerators • 1 46,832 MWh renewable energy for electricity generated at our facilities (includes electricity generated from landfill gas sold to the grid for Orion and excludes on-site PPAs) • 4 .54 m3/vehicle water intensity reduction at our facilities • 3 1 Certified Wildlife Habitats Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 5

2021 Sustainability Highlights 2040 Carbon neutral goal by 2040 and Science Based Target initiative (SBTi) approved targets for operations and products 1M+ Planned units of EV capacity in each of North America and China by 2025 $35B+ Planned investment from 2020 to 2025 in EVs and AVs 2035 Announced plan to eliminate tailpipe emissions from all new light-duty vehicles by 2035 $7B Announced investment in four Michigan manufacturing sites for a significant expansion of battery cell and EV assembly capacity in the United States 50% Manufacturing footprint in North America and China to be capable of EV production by 2030 100% Plan to source 100% renewable electricity at sites in the United States by 2025 and globally by 2035 $750M Planned investment of nearly $750 million through 2025 to expand access to EV charging in the United States and Canada $50M In early 2022, we doubled our Climate Equity Fund pledge to help ensure the people and communities most affected by climate change are not left behind Zevo 600 Delivered first all-electric delivery vans, with the Zevo 600 being the fastest vehicle to market in GM history 5K Expected to create 4,000 new jobs and retain 1,000 jobs in four Michigan manufacturing sites 3 Deployed three strategic pillars—DEI Maturity, Transparency and Talent Innovation—to drive DEI integration throughout the enterprise EEO-1 Published consolidated EEO-1 data for the first time 100K+ Ultium Charge 360 enables access, using GM mobile apps 1 , to more than 100,000 charging plugs throughout the United States and Canada 1 A vailable on select Apple and Android devices. Service availability, features and functionality vary by vehicle, device and the plan you are enrolled in. User terms apply. 2021 Recognitions Placed on the Bloomberg Gender Equality Index (GEI) 4th year in a row Diversity Inc Top 50 Companies for Diversity 6 years in a row 5th year for the World Index and 7th consecutive year as the only automaker on the North American index and a first-in-our-industry Gold Award Ranked 2nd among top U.S. auto companies in 2022 CDP Climate and Water Security A List 3rd year in a row 2022 World’s Most Ethical Companies ® 3rd year in a row and the only automotive original equipment manufacturer to be recognized on the list Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 6

Our Climate Action Framework for an Equitable Transition Our future is electric and includes everyone. Climate change affects different communities in different ways. As we move toward a carbon neutral future, we must lead positive change and implement inclusive solutions that address everyone’s unique needs, especially those of the communities where we live and work. In 2021, we put forth a Climate Action Framework to help guide our actions as our industry and company undergo a fundamental shift in mobility. Building on our philanthropic commitment to equitable climate action, GM has announced that we will provide an additional $25 million through our Climate Equity Fund, dedicating a total of $50 million to help close equity gaps in the transition to EVs and other sustainable technologies. To date, grants have been made to 19 nonprofit organizations that are helping to implement inclusive solutions for a zero-emissions, carbon neutral future. Read more about GM’s impact through the Climate Equity Fund on page 101 . FOCUS AREAS Future of Work Current and future employees will have a role to play in GM’s transition to an EV portfolio, and we will invest in necessary training and reskilling to make that transition. EV Access Achieve through a wide range of EVs across most segments and price points. Infrastructure Equity Committing to accessible charging solutions that can help meet customers where they are and understanding the need to help address charging deserts and other scenarios that can hinder EV ownership. Climate Equity Funding organizations that are helping to close the climate equity gap at the community level. PRINCIPLES • Help make mobility safe, accessible and environmentally friendly for all. • Incorporate and normalize equity considerations across our business operations and program implementation efforts, including workforce strategy, sustainability efforts, and products and services. • Work with community-based stakeholders to identify their unique needs, assets and priorities as well as collaboratively assist impacted communities. • Advocate for inclusive and equitable climate change action, renewable energy and transportation-related policies at the federal, state and local levels. • Help support organizations that are providing equitable access to a more sustainable future. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 7

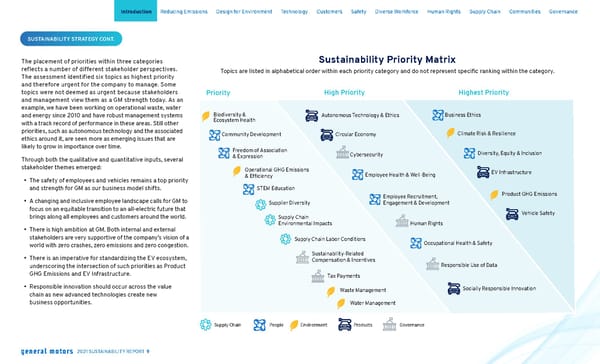

Sustainability Strategy GM’s sustainability strategy is led at the enterprise level to ensure a holistic approach across the company. Sustainability is overseen by the Board. GM’s sustainability strategy is led by senior leaders throughout the organization. Our chief sustainability officer is the enterprisewide leader of sustainability and directs initiatives through the Office of Sustainability. The Office of Sustainability has been strategically designed to ensure accountability for key sustainability targets and initiatives at the highest levels of the company; nurture a culture of sustainability across the organization; track and measure progress through transparent disclosure; and engage with both internal and external stakeholders on relevant matters. The Office of Sustainability leaders are charged with innovating and advocating as well as supporting social responsibility and transparent corporate practices. Our Sustainability Office uses a “team of teams” approach to help ensure that functional areas across the enterprise have accountability for their respective functions’ role in accelerating the company’s vision. Within each functional area, a single leader represents sustainability objectives and priorities, and owns sustainability goals and metrics. The teams focus on environmental and social aspects of sustainability. For example, a representative from engineering who sources cobalt for battery development works with the representative from supply chain to help ensure cobalt is sourced through strategic partnerships in an ethical manner that respects human rights. Sustainability Priority Assessment We prioritize sustainability topics by engaging with our stakeholders to understand those topics most relevant to them and our business, and those that offer the greatest opportunity to create meaningful shared value. This process is formally conducted through an assessment, and we performed our most recent assessment in 2021. We plan to conduct similar assessments every two to three years so that it takes into account emerging sustainability issues, macro events and current dynamics in the world around us. We performed our assessment in collaboration with a third party who guided us through a four-part process aligned with the GRI materiality principle for sustainability reporting. Identify a list of sustainability topics relevant to GM and the automotive industry. Understand stakeholder perspectives and priorities through an internal survey of more than 100 GM employees as well as 40 interviews with internal and external stakeholders. Score the topics based on quantitative and qualitative inputs. Prioritize the topics through the development of a tiered matrix as shown on the next page. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 8

SUSTAINABILITY STRATEGY CONT. The placement of priorities within three categories reflects a number of different stakeholder perspectives. The assessment identified six topics as highest priority and therefore urgent for the company to manage. Some topics were not deemed as urgent because stakeholders and management view them as a GM strength today. As an example, we have been working on operational waste, water and energy since 2010 and have robust management systems with a track record of performance in these areas. Still other priorities, such as autonomous technology and the associated ethics around it, are seen more as emerging issues that are likely to grow in importance over time. Through both the qualitative and quantitative inputs, several stakeholder themes emerged: • The safety of employees and vehicles remains a top priority and strength for GM as our business model shifts. • A changing and inclusive employee landscape calls for GM to focus on an equitable transition to an all-electric future that brings along all employees and customers around the world. • There is high ambition at GM. Both internal and external stakeholders are very supportive of the company’s vision of a world with zero crashes, zero emissions and zero congestion. • There is an imperative for standardizing the EV ecosystem, underscoring the intersection of such priorities as Product GHG Emissions and EV Infrastructure. • Responsible innovation should occur across the value chain as new advanced technologies create new business opportunities. Sustainability Priority Matrix Topics are listed in alphabetical order within each priority category and do not represent specific ranking within the category. Priority Biodiversity & Ecosystem Health Community Development Freedom of Association & Expression Operational GHG Emissions & Efficiency STEM Education Supplier Diversity Supply Chain Environmental Impacts Supply Chain Labor Conditions Sustainability-Related Compensation & Incentives Tax Payments Waste Management Water Management High Priority Autonomous Technology & Ethics Circular Economy Cybersecurity Employee Health & Well-Being Employee Recruitment, Engagement & Development Human Rights Occupational Health & Safety Responsible Use of Data Socially Responsible Innovation Highest Priority Business Ethics Climate Risk & Resilience Diversity, Equity & Inclusion EV Infrastructure Product GHG Emissions Vehicle Safety Supply Chain People Environment Products Governance Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 9

KRISTEN SIEMEN A conversation with our Chief Sustainability Officer As climate transition strategies continue to make headlines, the focus on social issues is also on the rise. How is GM working to address an equitable transition? We know that, across the globe, no two communities are impacted by climate change in the same way. Last year, we announced our Equitable Climate Action initiative to ensure that our transition to an all-electric, carbon neutral future is an inclusive one for our current and future workforce, customers and communities that may be more likely to disproportionately experience the effects of climate change. This initiative is rooted in four key areas: the future of work, EV access, infrastructure equity and climate equity. It’s a fact that the realities of climate change aren’t the same in every community—and that means the solutions can’t be the same either. As we move to a carbon neutral future, it is on us to lead positive change and implement inclusive solutions that bring everyone along. What have been your priorities in your first year as CSO? Where do you intend to focus your efforts? In my first year as CSO, my priority has been to ensure our sustainability strategy connects to our overall corporate vision. Our commitment to a vision of a world with zero crashes, zero emissions and zero congestion positions us to become a leader in the industry. As we implement our growth strategy, we have an opportunity—and an obligation—to create a better future for everyone. The pursuit of a safe and sustainable world is a passionate movement within GM; one that’s gaining momentum as our technologies reveal their increasingly profound potential. As a leader, an engineer and a mom, I am here to help break down barriers and advance our plans toward creating a world with zero emissions for generations to come. What are the most critical challenges we are facing as an industry as we transition to all-electric vehicles, and how are we working toward achieving our carbon neutral ambition? Announcing our vision of a world with zero crashes, zero emissions and zero congestion has led to important business growth and innovation—primarily in our AVs and EVs. We have put in place a cohesive strategy and set science-based targets aligned with the Paris Agreement. Our goals include a plan to introduce more than 30 EV models globally by 2025, become carbon neutral in our global products and operations by 2040 and source 100% renewable electricity at sites in the United States by 2025 and globally by 2035. One of the most critical challenges we face is that we cannot reach the future we envision alone—we must continue to pursue opportunities for collaboration with stakeholders across the globe, including suppliers, dealers, policymakers, climate thought leaders and others. A shift this massive requires everybody in, working together toward a single goal—an inclusive, all-electric future. Because talent and recruitment have never been more important, how is GM fostering a culture of inclusion and integrating sustainability across the enterprise? When our CEO, Mary Barra, announced our ambition to be the most inclusive company in the world, it was intended to reflect our approach to shaping our own workplace culture, as well as how we want to impact the world on the journey to a more sustainable future. Our path to innovation starts and ends with our employees, who are fundamental to the vibrancy and success of our company. That is why we have established employee development programs that address both individual and business needs, as well as effective recruitment programs that reach out to diverse populations. In addition, we are continuing to evolve our hiring and employee engagement practices to attract, engage and develop critical skills and best-in-class talent with diverse backgrounds and experiences. “Everybody in” is the rallying cry of GM’s transition to an all-electric future. GM wants to put everyone in an EV, and our aspiration to be the most inclusive company in the world will accelerate that mission. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 10

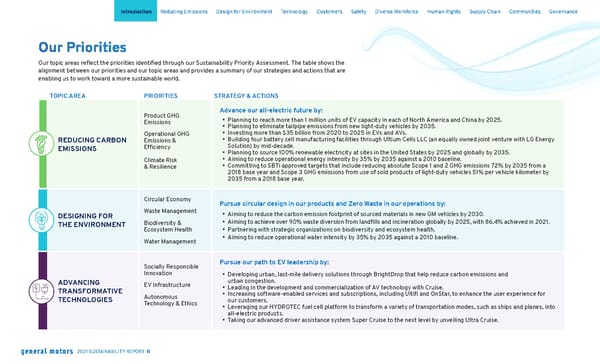

Our Priorities Our topic areas reflect the priorities identified through our Sustainability Priority Assessment. The table shows the alignment between our priorities and our topic areas and provides a summary of our strategies and actions that are enabling us to work toward a more sustainable world. TOPIC AREA PRIORITIES STRATEGY & ACTIONS REDUCING CARBON EMISSIONS Product GHG Emissions Operational GHG Emissions & Efficiency Climate Risk & Resilience Advance our all-electric future by: • Planning to reach more than 1 million units of EV capacity in each of North America and China by 2025. • Planning to eliminate tailpipe emissions from new light-duty vehicles by 2035. • Investing more than $35 billion from 2020 to 2025 in EVs and AVs. • Building four battery cell manufacturing facilities through Ultium Cells LLC (an equally owned joint venture with LG Energy Solution) by mid-decade. • Planning to source 100% renewable electricity at sites in the United States by 2025 and globally by 2035. • Aiming to reduce operational energy intensity by 35% by 2035 against a 2010 baseline. • Committing to SBTi approved targets that include reducing absolute Scope 1 and 2 GHG emissions 72% by 2035 from a 2018 base year and Scope 3 GHG emissions from use of sold products of light-duty vehicles 51% per vehicle kilometer by 2035 from a 2018 base year. DESIGNING FOR THE ENVIRONMENT Circular Economy Waste Management Biodiversity & Ecosystem Health Water Management Pursue circular design in our products and Zero Waste in our operations by: • Aiming to reduce the carbon emission footprint of sourced materials in new GM vehicles by 2030. • Aiming to achieve over 90% waste diversion from landfills and incineration globally by 2025, with 86.4% achieved in 2021. • Partnering with strategic organizations on biodiversity and ecosystem health. • Aiming to reduce operational water intensity by 35% by 2035 against a 2010 baseline. ADVANCING TRANSFORMATIVE TECHNOLOGIES Socially Responsible Innovation EV Infrastructure Autonomous Technology & Ethics Pursue our path to EV leadership by: • Developing urban, last-mile delivery solutions through BrightDrop that help reduce carbon emissions and urban congestion. • Leading in the development and commercialization of AV technology with Cruise. • Increasing software-enabled services and subscriptions, including Ultifi and OnStar, to enhance the user experience for our customers. • Leveraging our HYDROTEC fuel cell platform to transform a variety of transportation modes, such as ships and planes, into all-electric products. • Taking our advanced driver assistance system Super Cruise to the next level by unveiling Ultra Cruise. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 11

This is a modal window.

OUR PRIORITIES CONT. TOPIC AREA PRIORITIES STRATEGY & ACTIONS KEEPING PEOPLE SAFE Vehicle Safety Occupational Health & Safety Personal Safety Approach safety holistically by: • Creating a culture of safety through governance mechanisms and strategies that “Live values that return people home safely. Every Person. Every Site. Every Day.” • Applying safety advocacy, research and technology to focus on the safety of drivers, passengers and those outside the vehicle through our safety brand, Periscope. • Working with world-class research institutes to study how current safety technologies are making a real-world difference on the path to zero crashes. • Deploying various advanced driving technologies, such as forward collision alert, as standard equipment on select models across our product portfolio. • Providing our customers with OnStar safety services, in and beyond the vehicle, keeping them connected to 24/7 emergency support from specially-trained OnStar Advisors. DEVELOPING TALENTED & DIVERSE PEOPLE Diversity, Equity & Inclusion Employee Engagement, Retention & Development Freedom of Association & Expression Employee Health & Well-Being Advance our aspiration to be the most inclusive company in the world by: • Enhancing talent recruiting practices to attract a more diverse pool of candidates through programs that create new entry pathways into our workforce. • Building a positive work environment by creating a place where employees feel inspired to do their best work and feel valued for doing it. • Providing professional training and development opportunities for all employees at all levels to optimize their full potential. • Offering competitive benefits and promoting work-life balance by adopting new philosophies such as “Work Appropriately” to accommodate on-site, remote and hybrid work options. • Improving DEI through recommendations from our Inclusion Advisory Board of internal and external leaders, led by Chair and CEO Mary Barra. • Improving DEI maturity throughout our global business by leveraging ERGs, nearly all of which have executive-led advisory councils to help them advance and address issues and opportunities. • Supporting freedom of association and expression by working with 28 unions globally that represent 99% of our represented workforce and 61% of our total global workforce. UPHOLDING HUMAN RIGHTS Human Rights Respecting rights of all people within our value chain by: • Creating a strengthened Human Rights Policy , which was approved by the Board in 2021. • Utilizing the Cobalt Reporting Template, Mica Reporting Template and Conflict Minerals Reporting Template with our in-scope suppliers to support conflict mineral supply chain due diligence. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 12

OUR PRIORITIES CONT. TOPIC AREA PRIORITIES STRATEGY & ACTIONS SUPPORTING SUPPLIER RESPONSIBILITY Supply Chain Environmental Impacts Supply Chain Labor Conditions Supplier Diversity Build strong, transparent and trusted relationships with our suppliers in pursuit of an inclusive, zero-emissions future by: • Assisting suppliers in sourcing renewable energy for electricity through the GM Supplier Renewable Energy Solutions program. • Publishing the GM Sustainability Partner Guide and Framework for our Tier I suppliers to communicate our supply chain goals, priorities and processes. • Collaborating inside and outside the automotive industry to build sustainable and socially responsible supply chains by participating in programs such as Responsible Business Alliance, Responsible Minerals Initiative, Initiative for Responsible Mining Assurance and Global Platform for Sustainable Natural Rubber. • Spending of approximately $3.8 billion in 2021 with North America diverse Tier I suppliers for direct materials. • Inviting our Tier I suppliers to sign our Environmental, Social and Governance (ESG) Partnership Pledge. BUILDING MORE INCLUSIVE COMMUNITIES Community Development STEM Education Climate Risk & Resilience Create inclusive and sustainable solutions within the communities we live and work by: • Putting forth a Climate Action Framework for an equitable transition to help guide our actions as our industry and company undergo a fundamental shift in mobility. • Committing $50 million to a Climate Equity Fund to lead positive change and implement inclusive solutions that bring along everyone in the transition to an all-electric future. • Providing philanthropic support that helps develop community opportunities, support science, technology, engineering and mathematics (STEM) education and improve vehicle and road safety. • Promoting progress in our hometown of Detroit through a $50 million commitment to support nonprofits, education, employment and neighborhood revitalization efforts. ENSURING RESPONSIBLE GOVERNANCE Sustainability-Related Compensation & Incentives Business Ethics Ensure full transparency and ethical integrity throughout all operations by: • Enhanced Board oversight of ESG risk. • Integrating sustainability principles throughout the company’s business strategy, including management of climate change risk. • Incorporating robust cybersecurity and privacy protection policies and procedures as critical enablers of our digital transformation. • Creating and maintaining an ethical culture across all levels of our global workforce. • Adopting EV performance measures (including EV volume, launch timing and launch quality) for our long-term incentive plan to further align our executive compensation programs with our all-electric future and placing additional focus on GM’s growth and ESG performance. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 13

Reducing Carbon Emissions IN THIS SECTION The Journey to Zero Emissions 15 Accelerating an Inclusive All-Electric Future 16 Leveraging the Ultium Platform 17 Creating a Superior EV Ownership Experience 18 A Purpose-Built EV Portfolio 19 Growing the EV Market & Charging Infrastructure 21 Transforming a World-Class Manufacturing Footprint 22 Factory ZERO: How Our Future Looks 23 Reducing Emissions From ICE Vehicles 24 Conserving Energy in Our Facilities 25 Accelerating an All-Renewable Future 27 Our Strengths y Providing the talent, manufacturing scale, customer insights, as well as battery and software technology necessary to lead in an all-electric future y Changing consumer perceptions of what electric vehicles (EVs) can be by offering products across a range of price points and segments, from small crossovers to sport utility vehicles and trucks y Using our scale to help accelerate the renewable energy industry Our Opportunities y Helping consumers better understand, accept and adopt EVs as their choice for personal mobility y Achieving price and range parity between EVs and internal combustion engine (ICE) vehicles y Continuing to establish collaborative and coordinated public-private partnerships to help accelerate the buildout of charging infrastructure y Securing complementary national government policies to support charging infrastructure, renewable energy investments and EV adoption Edition 1 Pickup limited availability by waitlist. Additional GMC HUMMER EV models available Fall 2022. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 14

The Journey to Zero Emissions Our vision is a future with zero emissions to help create a more sustainable planet. GM plans to: Become carbon neutral in global products and operations by 2040. Achieve approved Science Based Target initiative ( SBTi) targets for operations and products. Meet our commitments under the Business Ambition Pledge for 1.5°C, an urgent call to action from a global coalition of United Nations agencies, businesses and industry leaders. Work with federal, state and local governments for implementation of supportive policies to move the United States closer to carbon neutrality consistent with the goals of the Paris Agreement. Collaborate with suppliers to set ambitious targets for the supply chain to reduce emissions, increase transparency and source more sustainable materials. Everybody in As we transition to an all-electric future, we will apply our climate equity framework to help ensure an equitable transition. 2% SCOPE 1 & 2 Strategic Plans • Plan to source 100% renewable electricity at sites in the United States by 2025 and globally by 2035. • Target a reduction in operational energy intensity by 35% by 2035 against a 2010 baseline. 14% SCOPE 3—Purchased Services and Supply Chain 2 Strategic Plans • Inviting our Tier I suppliers to sign the GM ESG Partnership Pledge to show their commitment to the principles of sustainability and human rights. • Monitor our suppliers' environmental and social progress through CDP and EcoVadis. • Leverage the GM Partner Sustainability Framework for suppliers to set goals. 84% SCOPE 3—Use of Sold Products 1 Strategic Plans • Take action to reach 1M+ planned units of EV capacity in each of North America and China by 2025. • Plan to achieve sales of 40% to 50% of annual U.S. volumes of EVs by 2030. • Plan to eliminate tailpipe emissions from new light-duty vehicles by 2035. From everybody in to everything in We have the opportunity to extend our electric and fuel cell technologies beyond light-duty vehicles to other transportation modes such as rail, shipping and heavy-duty trucks. Learn more . 1 A ligned with the SBTi for Scope 3, use of sold products. The SBTi standards require well-to-wheel (from fuel production to vehicle driving) for vehicle CO2 intensity (gCO2/km) calculations. We have revised our numbers for 2018 through 2020 for this requirement. Going forward, GM will use the SBTi standards in calculating vehicle CO2 intensity. 2 Inc ludes other Scope 3 categories. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 15

Accelerating an Inclusive All-Electric Future Climate change needs to be addressed, and we want to be part of the solution by putting everyone in an EV. We accelerated our plans to transition to an all-electric future in 2021 when we announced increased investments in EV and autonomous vehicle (AV) development to more than $35 billion from 2020 through 2025 from our initial target of $20 billion. We also announced plans to introduce more than 30 EVs globally by the end of 2025, with more than two-thirds of these available in North America. These introductions, along with additional EVs being planned, should position us to have EVs represent 40% to 50% of annual U.S. sales volume by 2030. To reach this upper range, we will continue to work with federal, state and local governments for implementation of supportive policies to move the United States closer to carbon neutrality consistent with the goals of the Paris Agreement. In China, the world’s largest EV market, we will accelerate electrification through a plan in which 40% of new vehicles introduced through the end of 2025 will be EVs. This will build on our current market momentum in China. Based on our planned cadence of EV introductions, by the end of 2025, GM will have more than 1 million units of EV capacity in North America. This is in addition to more than 1 million units of EV capacity in China over the same time frame. Our EV portfolio is planned to be among the broadest in the industry with entries from affordable, high-volume market segments to top-of-the-line models and everything in between. The new all-electric GMC HUMMER EV and upcoming Cadillac LYRIQ , Chevrolet Silverado EV and Chevrolet Equinox EV feature the company’s Ultium platform, a combined EV architecture and propulsion system, which enables EVs at scale, across a broad set of lifestyles and price points. EVGRO is our dedicated team leading efforts to drive mass consumer adoption of EVs. This team combines startup agility with the broad strength of GM to minimize complexity and turn quick decisions into actionable programs across the enterprise, while leveraging cross-functional expertise and creativity. With projects spanning the EV ecosystem—from EV shopping to charging solutions—the team is working to reimagine the end-to-end customer experience by leveraging a broad array of collaborations and partnerships, including our dealer network, which represents a key competitive advantage. How We’re Driving EV Adoption The company’s Ultium platform, a combined EV architecture and propulsion system, enables EVs at scale, across a broad set of lifestyles and price points. EV education and engagement programs to maximize the ownership experience. A product lineup that complements a broad set of services to support residential and commercial energy options. Innovative energy solutions. Investments and collaborations in public and community charging networks. Reimagined service convenience. Creating a world-class digital retail experience. Connected services for a reimagined ownership experience, centered around the myBrand mobile app 2 . Turnkey services, such as home and fleet charging solutions. The Wuling Hong Guang MINIEV has been #1 in sales in the world’s largest new energy vehicle (NEV) market for 16 consecutive months from its launch in July 2020 to December 2021. The model also was the best-selling NEV model in the entire world for five months during 2021. 1 1 A ccording to EV Sales a market research organization. 2 A vailable on select Apple and Android devices. Service availability, features and functionality vary by vehicle, device and the plan you are enrolled in. User terms apply. 2023 Cadillac LYRIQ Debut Edition available Summer 2022, by reservation only. Additional LYRIQ models available starting Fall 2022. See dealer for details. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 16

Leveraging the Ultium Platform Our EV strategy leverages a highly flexible global EV platform powered by our proprietary Ultium propulsion system. GM’s Ultium-based EVs are powered by rectangular, pouch-style battery cells that are simple, lightweight and space-efficient. Our ability to stack the long pouch cells vertically or horizontally is unique in the industry and allows for a flat cabin floor and more interior room than comparable EVs that use cylindrical battery packs. This platform can power mobility across a broad range of price points from luxury vehicles to work trucks to high-performance vehicles. As a result, Ultium is enabling GM to compete on an entirely new level and pursue nearly every customer type and preference in the market. In 2021, we increased our vertical integration of key supply chains to accelerate technology adoption, drive down costs and mitigate supply chain risks. One of these initiatives includes next-generation silicon carbide devices that will be used in the integrated power electronics contained within Ultium Drive units in next- generation EVs. The device enables system efficiencies while lowering weight and conserving space. We also are working to reduce supply chain risks by improving supplies of heavy and light rare earth materials and magnets, copper and electrical steel—all critical components used in the manufacturing of electric motors for automotive and renewable power generation. As an example, we are forming a strategic relationship and commercial collaboration with Controlled Thermal Resources to secure local and low-cost lithium from the Salton Sea area of California. This lithium will be produced through a closed-loop, direct extraction process that results in a smaller physical footprint, no production tailing and lower carbon emissions when compared to traditional processes like pit mining or evaporation ponds. Importantly, the agreement positions us to source lithium through a U.S. supplier. These initiatives help us ensure availability of critical materials, drive supply chain innovation and, ultimately, deliver both higher-quality and more affordable vehicles to our customers. Ultium: A Revolutionary EV Platform Built on a flexible battery architecture for the production of EVs across different vehicle types with outstanding power, range and performance. 300+ miles 1 GM-estimated range of up to 300+ miles. 10 minutes 2 Level 2 and direct current (DC) fast charging with the capability to charge nearly 100 miles of range in 10 minutes. 50 to 200 kWh Battery energy storage ranging from 50 to 200 kWh. Ultium Drive Ultium Drive units to support front-wheel, rear-wheel, all-wheel and performance all-wheel drive applications. ~3 seconds GM-estimated acceleration of 0 to 60 mph in as little as approximately 3 seconds on the GMC Hummer EV. 1 A ctual range will vary based on several factors, including temperature, terrain, battery age, loading, use and maintenance. 2 GM-estimated. Actual charge times will vary based on battery condition, output of charger, vehicle settings and outside temperature. → Learn More about our Battery Chemistry Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 17

LEVERAGING THE ULTIUM PLATFORM CONT. Ultium represents a milestone achievement in electrification, with battery pack costs nearly 40% lower compared to the previous generation, and we expect the second generation Ultium packs will cost nearly 60% less than the batteries used today 1 . We are committed to continuous manufacturing, materials and packaging efficiencies, high-energy cell design and increased vertical integration with local production that are expected to deliver greater energy density at a lower cost. We also are incorporating responsible battery recycling considerations. Today we refurbish, recycle or reuse 100% of batteries returned to us and apply the lessons in future design. Among the recycling initiatives that we are pursuing is a collaboration with the Department of Energy’s (DOE) U.S. Advanced Battery Consortium and recyclers to advance lithium-ion battery recycling. These projects are validating recycled materials as alternatives to mined materials for battery manufacturing with the goal of reducing future needs for mining. Learn more in Design for the Environment . Creating a Superior EV Ownership Experience In 2021, GM introduced Ultium Charge 360, a holistic approach that integrates charging networks, GM vehicle mobile apps, products and services to simplify the overall charging experience. Through Ultium Charge 360, GM Fleet, OnStar Business Solutions (where available) and BrightDrop, customers will be able to customize plans and select from preferred providers for their fleet electrification needs in the United States and Canada. 2 Ultium Charge 360 Capabilities • Access to Charging: GM continues to work with a variety of third parties, including charge point operators, electric utilities and government agencies to make home, workplace, public and fleet charging ubiquitous and easy for customers. • Mobile Apps: We will continue to update GM vehicle mobile apps to provide an even more intuitive mobile experience that simplifies navigating to a charging station, initiating charging sessions and paying for charging. • Products and Services: To help ensure a seamless EV transition, GM plans to offer EV owners charging accessories and installation services tailored to their lifestyle. A Holistic Solution for Fleets • A comprehensive solution to help new and existing fleet customers identify providers, tools and solutions required to plan, finance, deploy and operate charging infrastructure in fleet yards and depots. • Fleet and facility management tools. • Integration with GM’s fleet management solution, OnStar Vehicle Insight and the BrightDrop Software Platform. • Support for a wide range of fleet segments, including delivery, sales, utilities and motor pool. Convenient and Rewarding Ownership Experience • Implementing connected diagnosis and over-the-air programming with easy mobile service or dealer pick-up/drop-off options for service convenience. • Competitive battery warranty with battery performance monitoring. • A seamless, omnichannel customer experience with connected product offerings. • Make the myBrand apps as the “ownership hub” to access connected services, monitor battery health and energy status and plan routes. 2024 Chevrolet Equinox EV RS available Fall 2023. Availability of LT shown to be announced at a later date. 1 C ost reduction might vary by region and cell chemistry. 2 A vailable on select Apple and Android devices. Service availability, features and functionality vary by vehicle, device and the plan you are enrolled in. User terms apply. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 18

→ A Purpose-Built EV Portfolio The EV portfolio that we are building today is designed to meet the needs of a broad range of customers. We have the advantage of the most loyal customer base in the industry and intend to reward that loyalty with a convenient and seamless transition to an electric future. U.S. EV Models 2022 Chevrolet Bolt EV/EUV The 2022 Bolt EV and Bolt electric utility vehicle (EUV) both launched in summer 2021. The Bolt EUV has an EPA-estimated range of 247 miles on a full charge . 1 2022 GMC HUMMER EV Pickup 1, 2 As the world’s first zero-tailpipe-emissions, all-electric supertruck, the GMC HUMMER EV is built to navigate off-road conditions. A 24-module pack of Ultium battery cells offers a GM-estimated range of up to 329 miles. 2023 Cadillac LYRIQ 3 Cadillac’s introduction of its electric portfolio begins with the debut of the LY R I Q —a fully electric luxury crossover is expected to offer a GM-estimated range of over 300 miles per full charge. It will also offer the enhanced version of Super Cruise . 2022 BrightDrop Zevo 600 The BrightDrop Zevo 600 is an electric light commercial vehicle (eLCV) built for the delivery of goods and services over long ranges and is the fastest vehicle to market in GM’s history. 2024 Chevrolet Silverado EV 1, 4 The Silverado EV is expected to offer customers a GM-estimated range of 400 miles on a full charge and will feature an available fixed- glass roof for retail models, offering an experience of spaciousness. 2024 Chevrolet Equinox EV SUV and 2024 Chevrolet Blazer EV SUV Both models will be available in 2023. These two products, along with the Chevrolet Silverado EV, will place Chevrolet EVs in the industry’s two largest segments and one of the fastest-growing segments in the United States. Cadillac CELESTIQ 5 The Cadillac CELESTIQ will represent the ultimate expression of Cadillac innovation. The luxury sedan will offer all-wheel drive , four- wheel steering and a full-glass roof that allows each occupant of the vehicle to set their own level of transparency. 1 A ctual range will vary based on several factors, including temperature, terrain, battery age, loading, use and maintenance. 2 E dition 1 Pickup limited availability by waitlist. Additional GMC HUMMER EV models available Fall 2022. Available on EV3X based on a full charge. GM estimated. 3 2 023 Cadillac LYRIQ Debut Edition available Summer 2022, by reservation only. Additional LYRIQ models available starting Fall 2022. See dealer for details. 4 S ilverado EV RST GM-estimated range on a full charge based on current capability of analytical projection consistent with SAE J1634 revision 2017—MCT. Model year 2024 Silverado EV available Fall 2023. 5 C oncept vehicle. Not available for sale. Learn more about our Ultium effect Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 19

China EV Models 2021 BAOJUN KiWi EV 1 The KiWi EV has a NEDC-estimated range of 305 kilometers on a full charge and supports DC fast charging , which enables it to be charged from 30% to 80% in one hour. Buick VELITE 6 EV 2 Range of up to 518 kilometers and supports fast charging from 30% to 80% capacity in just 30 minutes. 2022 Chevrolet Menlo The sporty-looking sedan is the brand’s first all-electric vehicle in China. The 2022 Chevrolet Menlo has an extended NEDC-estimated range of up to 518 kilometers on a single charge. 2022 Wuling Hong Guang MINIEV The Hong Guang MINIEV is China’s #1 selling EV, an affordable four-seat runabout that is fun to personalize. Rong Guang EV The Rong Guang EV is Wuling’s first electric minivan for the commercial vehicle market. 1 T he 2022 BAOJUN KiWi EV will be launched in the second half of 2022. 2 T he up to 518km range on a full charge is based on China Light-duty Vehicle Test Circle (CLTC). Actual fast-charging time may vary based on several factors, including temperature and external power environment. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 20

Growing the EV Market & Charging Infrastructure In the transition to an all-electric future, automakers must meet customer expectations relating to range, charging, battery and ownership. Our charging infrastructure strategy seeks to help solve these concerns. GM Charging Infrastructure Initiatives in the United States and Canada Nearly $750M planned investment through 2025 to expand charging for residences, workplaces and public areas. 3,250 EVgo DC fast charging (DCFC) stalls installed through 2025. 10 Signed agreements with major charging providers that include Blink Charging, ChargePoint, EV Connect, EVgo, FLO, Greenlots, EvGateway, EV Passport, PlugShare and SemaConnect. Up to 40,000 Level 2 EV chargers to be deployed as part of a Dealer Community Charging Program through 2025. This will help address gaps in public charging availability, including “charging deserts” in rural and underserved communities, by providing participating EV dealers up to 10 Ultium Level 2 charging stations. 100,000+ Ultium Charge 360 enables access, using GM mobile apps 1 , to more than 100,000 charging plugs. GM’s strategy to grow the EV market begins at the retail level, with initiatives to educate dealer partners, create a network of EV experts and engage customers to drive EV awareness, consideration and sales. Key pillars to GM’s strategy to grow the EV market include: • An all-new Electric Vehicle Experience Standards Program for participating dealerships. Through the program, each dealership designates an “EV Specialist” to champion the EV selling process at the store. • Access to “EV Academy” and dedicated EV training courses for the EV Specialist to help them navigate customers through the charging experience, all while maintaining GM standards for customer satisfaction. Training is expected to include quarterly training courses as identified by the GM Center for Learning, and enrolled specialists must achieve a 100% training percentage each quarter. • A new “gamification” microtraining platform to supplement EV training and drive EV literacy. • “EV Live,” a new platform to educate and guide dealers, customers, fleets and other parties with access to on-demand interactive training and consultation. • An “EV Learn” feature of the myBrand mobile apps 1 to allow shoppers insight into the EV ownership experience, including a cost savings calculator. • Innovative digital engagement tools, both in the physical and digital retail space, to guide customers through the shopping process. The Electric Vehicle Experience Standards Program provides dealers the opportunity to earn a monthly incentive for participating in initiatives designed to deliver on these customer experience objectives for EVs. 1 A vailable on select Apple and Android devices. Service availability, features and functionality vary by vehicle, device and the plan you are enrolled in. User terms apply. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 21

Transforming a World-Class Manufacturing Footprint We are building our electric future by leveraging our existing manufacturing footprint as well as building new plants for battery cell production. We plan to rapidly scale EV manufacturing. Globally, we are adding battery assembly/pack facilities to our existing sites in North America and China and converting some propulsion facilities to the manufacturing of drive units. Since 2020, we have announced investments totaling more than $14 billion in 10 sites across North America to increase our manufacturing capacity in the region to more than 1 million EVs annually by the end of 2025. This is a key step to deliver on our target to achieve carbon neutrality in our global products and operations by 2040. We believe that leveraging established assembly plants for EV production reduces capital expenditures up to $1.5 billion per assembly plant versus building an all-new plant and enables us to go into vehicle production in less than half the time required of a greenfield plant. GM is investing $7 billion in four Michigan manufacturing sites, significantly increasing battery cell and electric truck manufacturing capacity. This is the single largest investment announcement in GM history. The investment includes construction of a new Ultium Cells battery cell plant in Lansing, Michigan and the conversion of GM’s assembly plant in Orion Township, Michigan for production of the Chevrolet Silverado EV and the electric GMC Sierra, GM’s second assembly plant scheduled to build full-size electric pickups. In 2021, we also announced the Wallace Battery Cell Innovation Center, an all-new facility is expected to significantly expand our battery technology operations and accelerate the development and commercialization of longer- range, more affordable EV batteries. The Center, located at our Global Technical Center in Warren, Michigan, is slated to be completed in mid-2022. The latest addition of 50,000 square feet brings the Center to 85,000 total square feet as demand for EVs increases. Investing in an All-Electric Future (Projects completed, in progress or announced through the first quarter of 2022 in the United States as examples of our transformation) By the end of 2025, GM plans to have more than 1 million units of EV capacity in North America. This is in addition to more than 1 million units of EV capacity in China over the same time frame. Battery Cell Manufacturing 1 Lansing, Michigan New $2.6 billion plant to supply battery cells to Orion and other GM assembly plants. Factor y ZERO Detroit Hamtramck, Michigan Retooling of existing manufacturing facility, representing a $2.3 billion investment. Electric Motor Component Plant Lockport, New York Renovation and new equipment installation, a $154 million investment. Battery Cell Manufacturing 1 Lordstown, Ohio A $2.3 billion investment to mass-produce Ultium battery cells. EV Truck Assembly Orion, Michigan Retooling of existing manufacturing facility through a $4 billion investment. EV Assembly Spring Hill, Tennessee A $2.3 billion retooling of an existing manufacturing facility. Battery Cell Manufacturing 1 A $2.3 billion investment to supply batteries to the Spring Hill assembly plant. Die Casting Foundry Bedford, Indiana More than $51 million invested to support drive unit castings for Silverado EV. 1 B uilt through Ultium Cells LLC (an equally owned joint venture with LG Energy Solution) Our manufacturing investments in four Michigan manufacturing sites are expected to create 4,000 new jobs and retain 1,000 jobs in Michigan. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 22

Factory ZERO: How Our Future Looks Walk through the doors of Factory ZERO in Detroit, Michigan, and you’ll not only see the launchpad for GM’s multibrand EV strategy but also GM’s low carbon future. From sourcing renewable energy to power the all-electric vehicles it will produce, the retooling of this 36-year-old facility is reflective of the company that GM is becoming. SUSTAINABLE Reused or recycled a wide range of materials that came out of the facility during conversion. • Roads on the plant site are made from crushed concrete from the old floor. • All operations are expected to be powered by sourcing 100% renewable energy for electricity by 2023. • The in-plant fleet of forklifts, tuggers and Seegrid AVs is powered by hydrogen fuel cells–a first for a GM plant. • Treated stormwater will be used in cooling towers and a fire suppression system. • A 16.5-acre wildlife habitat is home to monarch butterflies, foxes and turkeys. ELECTRIC All Factory ZERO EVs will be built on the Ultium Platform, the heart of our EV product strategy. Among the vehicles that are expected to call the plant home: • 2022 GMC HUMMER EV pickup, which began production in late 2021 • 2024 GMC HUMMER EV SUV • Chevy Silverado all-electric pickup • GMC Sierra all-electric pickup • Cruise Origin INCLUSIVE Our target to bring everyone along on our EV journey has started here. • Redesigned employee experience for all plant employees incorporates newly developed orientations led by plant leaders and centered around GM behaviors. • Workspaces and gathering areas are designed to encourage a climate of collaboration among all groups and levels of responsibility. • Employees actively recognize and share success. • Site leadership and employees actively participate in an operational excellence project focused on actions to promote an inclusive environment. COMPETITIVE The retooled facility is a model for future GM facility renovations. • Retooling requires only two-thirds of the capital required to build a greenfield plant. • GM projects that it will avoid up to $15 billion in capital costs by 2030 through the renovation of existing manufacturing facilities versus ground-up construction. • Through virtual tools and working in parallel with production engineering teams, manufacturing launch time is reduced from two years to less than one, as opposed to up to four years for greenfield planning and construction. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 23

Learn more about fuel efficiency and emissions regulation in the Public Policy section of this report. → Reducing Emissions From ICE Vehicles As we move closer to our vision of an all-electric portfolio, we also are improving the efficiency of ICE vehicles. Continual improvements in vehicle engine and transmission efficiency, as well as vehicle weight, have helped us to eliminate excess materials use in manufacturing, while reducing fuel use and costs for customers. For example, the 4WD Crew Cab Silverado has seen an improvement in tailpipe CO2 emissions of 25% from 2000 through 2020. 3 Within GM, we have institutionalized extensive governance processes that predict, plan, measure and assess our fleet’s fuel efficiency and emissions performance according to established government test procedures on a dynamic and country-by-country basis. Well-to-Wheel CO2 Emissions per Light-Duty Vehicle 1, 2 (gCO2e/km) 2018 2019 2020 USA 287 293 280 China 220 208 206 Brazil 200 198 195 Weighted Average 245 243 240 U.S. Light-Duty Fuel Economy Technologies Across the Fleet Percent of Total U.S. Light-Duty Volume Stop-Start (reduces fuel usage when the vehicle is stopped) 74% MY21 Engine/Transmission Thermal Management (warms up engine and transmission faster to reduce friction and losses) 56% MY21 Aero-Shutter (reduces aerodynamic drag) 83% MY21 High-Efficiency Alternators (72%+) (reduce losses from electricity generation) 88% MY21 1 2 021 data will be available mid-2022. 2 D ata has been restated to align with SBTi for Scope 3, Use of Sold Products. The SBTi standards require well-to-wheel (from fuel production to vehicle driving) for vehicle CO2 intensity (gCO2e/km) calculations. We have revised our numbers for 2018 through 2020 for this requirement. Going forward, GM will use the SBTi standards in calculating vehicle CO2 intensity. Numbers are inclusive of EV portfolio. 3 D ata prior to July 2009 corresponds to General Motors Corporation. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 24

Conserving Energy in Our Facilities Our goal to become carbon neutral in our operations will be achieved in part through an ambitious energy conservation and renewable energy program. An important pillar in GM’s carbon reduction strategy for Scope 1 & 2 emissions is to focus on energy efficiency. Globally, our plants continue to work on improving energy efficiency and reducing GHG emissions through the use of an energy management system (EnMS). In addition to our Science-Based Target goal for GHG emissions, GM expanded our energy intensity goal for operations to 2035 with a 35% reduction from a 2010 baseline. Following are some of the programs and strategies that we deploy to conserve energy in our operations. U.S. DOE 50001 Ready Program In 2021, 27 GM U.S. manufacturing facilities, or 93% of our U.S. manufacturing footprint, implemented the U.S. DOE 50001 Ready program. GM has implemented 50001 Ready at 27 manufacturing and two nonmanufacturing facilities—more than any other participating company. In 2021, we expanded the program to two nonmanufacturing sites in the United States, two plants in Canada and one in Mexico. We plan to expand this program to all manufacturing facilities globally to continuously monitor and improve our EnMS. Better Buildings Low Carbon Pilot We are participating in the DOE Better Buildings program to demonstrate pathways to achieve low or zero carbon in the operation of buildings and manufacturing plants. Energy Star’s Building Portfolio Manager (BPM) GM uses data analytics to measure and track energy consumption globally. BPM is an example of a tool that allows us to benchmark performance and make continuous improvements. 2021 Energy Star Certifications for Superior Energy Management • IT Innovation Centers in Texas and Arizona • Enterprise Data Centers (2) in Michigan • Flint Assembly • Fort Wayne Assembly GM Energy Strategy Increasing Energy Efficiency Reduce energy consumption at our facilities. Sourcing Renewables Source through direct investments, green tariffs and power purchase agreements. Addressing Intermittency Mitigate against gaps in renewable energy for electricity transmission. Policy Advocacy Work to drive down costs and increase renewable energy for electricity opportunities. Goal: Plan to source 100% renewable electricity at sites in the United States by 2025 and globally by 2035. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 25

CONSERVING ENERGY IN OUR FACILITIES CONT. Energy Star Challenge for Industry This continuous improvement program has recognized 69 GM plants multiple times over the past 10 years for a total of 130 recognitions. The Challenge is to reduce energy intensity by 10% within a five-year period. In 2021, five plants met the Challenge with an average 15% reduction over three years. The five plants were Qingdao Assembly, Baojun Assembly and Dongyue Engine, all in China, Silao Assembly in Mexico and Flint Assembly in the United States. Energy Star certifications provide a benchmark system for energy efficiency, identifying buildings and auto assembly plants within the top 25th percentile of operating efficiency. Energy OnStar This tool (unrelated to GM’s OnStar service), is a continuous commissioning system that monitors the performance of our HVAC equipment in real time. Approximately one-third of our operational energy use is heating and cooling, and the system allows us to quickly identify when a unit is malfunctioning and easily find opportunities for improvement. The Energy OnStar tool helped us optimally manage plant shutdowns in 2021 during the semiconductor shortage. Energy Star Treasure Hunts Through this process, we can engage nearly 100 team members to uncover quick ways to save energy. In 2021, we conducted 17 on-site and virtual energy treasure hunts, covering 61 million square feet of space, and found 175 opportunities that could potentially save the company $5 million. We also extended this approach to our suppliers during the year, including rolling out a Virtual Energy Treasure Hunt process. Learn more in Supporting Supplier Responsibility . A More Energy-Efficient Plant One of our energy efficiency projects in 2021 was at Fort Wayne Assembly, where we manufacture the Chevrolet Silverado and GMC Sierra full-size trucks. The 35-year-old plant generated steam with large natural gas boilers to heat the building and manufacturing processes. The Powerhouse also generates six megawatts of renewable electricity from landfill gas, a renewable fuel that would normally be flared, which we instead use to generate renewable electricity as part of our RE-100 target. The remainder of the plant’s electric loads are served by wind and solar and are 100% powered by renewable energy. The project will eliminate steam, an inefficient heating method, by using the waste heat from the landfill gas engines to supply most of the building heat and converting other steam loads to direct or indirect natural gas. Additional energy conservation measures include the installation of ultraviolet lamps in air handling units, lighting and dock heater controls. GM was recognized by the Michigan Battle of the Buildings in 2021 for manufacturing resiliency in the face of rapidly changing dynamics during the pandemic. In 2021, GM received recognition from Energy Star for Sustained Excellence in Energy Management for the 10th year, confirming our continuous improvement activities. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 26

Accelerating an All-Renewable Future In 2021, we accelerated our timeline for sourcing 100% of our electricity from renewable sources for our U.S. sites to 2025, five years earlier than previously announced and 25 years ahead of our initial target set in 2016. In doing so, we also will help drive growth in the renewable energy sector. Just as GM has the scale to promote widespread adoption of EVs, we also have the scale to help bring about a transition to renewable power sources across the United States. We are the 12th largest offtaker in the world 1 , and largest in the automotive industry, of renewable power purchase agreements by capacity. Reducing our own operational carbon footprint and setting up the grid for a future in which EVs can charge using renewable power for electricity is an essential part of our zero-emissions vision. By accelerating our renewable energy for electricity goal, GM aims to avoid 1 million metric tons of carbon emissions that could have been produced between 2025 and 2030. The accelerated U.S. goal will position us to continue working toward our goal of sourcing 100% renewable energy to power global operations by 2035. This U.S. goal builds upon approval of our targets. In 2021, the SBTi assessed GM’s official submission against the Call to Action’s eligibility criteria. The target submission for Scope 1 and 2 emissions is a reduction of absolute emissions of 72% by 2035 from a 2018 base year, which meets the minimum ambitions for a 1.5°C pathway. We are currently on track to meet the target by 2035 with 25% of our global electricity powered by renewable energy in 2021. Quantifying the Impact 5 the number of years we have accelerated our goal to source 100% renewable energy to supply electricity for our U.S. sites. 1M metric tons of potential carbon emissions avoided if we meet our goal by 2025 instead of 2030. The GHG emissions equivalent of 125,963 homes’ energy use annually. 1 BloombergNEF Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 27

ACCELERATING AN ALL-RENEWABLE FUTURE CONT. GM Renewable Energy for Electricity Initiatives 1 MI—Consumers Energy G r e e n Ta r i f f 100 MW MI—DTE G r e e n Ta r i f f 447 MW IN—On-Site Landfill Gas Fort Wayne Assembly—6.4 MW MI—On-Site Landfill Gas Orion Assembly—8 MW Toledo, OH On-Site Solar 1.8 MW Rochester, NY On-Site Solar 0.345 MW Rancho Cucamonga, CA Solar PPA (Rooftop) 3 MW Hilltopper, IL Wind PPA 100 MW Trishe, OH Wind PPA 103 MW Bowling Green, KY On-Site Solar 0.85 MW Cactus Flats, TX Wind PPA 50 MW Newport, AR Solar PPA 180 MW TN , KY—T VA G r e e n Ta r i f f 128 MW Hidalgo, TX Wind PPA 30 MW 1 F igure includes both operating and executed agreements. Total Capacity of Renewable Electricity 14.4 MW Landfill Gas 313.995 MW Solar 830 MW Wind Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 28

Our Energy & Emissions Progress Absolute Scope 1 & 2 Emissions (million metric tons CO2e) 2018 2020 2021 2019 Energy Intensity (MWh/Vehicle) (Energy used in GM’s operations) 2018 2020 2021 2019 2.31 2.13 2.06 2.25 1.50 Goal 2018 BASELINE 2019 2020 2021 2035 Renewable Energy as a Percentage of Global Electricity Use 2018 2020 2021 2019 2021 3% 22% 23% 25% 55% 1 2018 BASELINE 2019 2020 2021 2025 100% Goal 2035 21,489,324 Electricity Consumption (including cooling) Energy Consumption by Source (GJ) 21,048,701 Fuel Consumption From Nonrenewable Sources (including heating) 1,713,704 Fuel Consumption From Renewable Sources (including heating) 938,548 Steam Consumption ACCELERATING AN ALL-RENEWABLE FUTURE CONT. Energy intensity is a global calculation. 2021 performance was higher than prior years due to lower vehicle production driven by semiconductor shortages and other COVID-related constraints. 1 B ased on estimated forecasted global renewable energy sourced through currently executed agreements, subject to change depending on actual future electric usage in operations, and actual future renewable generation. Skip Navigation Introduction Reducing Emissions Design for Environment Technology Customers Safety Diverse Workforce Human Rights Supply Chain Communities Governance 2021 SUSTAINABILITY REPORT 29